Abstract

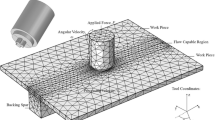

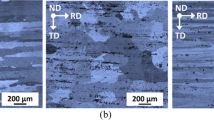

Dissimilar plates (0.6 cm thick) of copper and 6061 aluminum alloy; and 2024 aluminum alloy and 6061 aluminum alloy were friction-stir welded at various rotation speeds (400–1200 rpm) and traverse speeds of 1 to 3 mm/s, and produced variations of vortex and other swirl-like intercalations, especially near the weld-zone/work-piece interface. These vortex-like structures are composed of dynamically recrystallized, fine-grained intercalation microstructures which have been observed by optical metallography, scanning electron microscopy and transmission electron microscopy. They are similar to those characterizing mechanical alloying. Such microstructures are especially fascinating because although they resemble vortex instabilities which occur in turbulent fluids, they are formed by extreme deformation in the solid state since centerline temperatures through the weld zone are about 420°C, or ∼0.7 TM in the 6061 aluminum system.

Similar content being viewed by others

Author information

Authors and Affiliations

Additional information

Received: 21 July 1998 / Accepted: 28 August 1998

Rights and permissions

About this article

Cite this article

Murr, L., Li, Y., Flores, R. et al. Intercalation vortices and related microstructural features in the friction-stir welding of dissimilar metals. Mat Res Innovat 2, 150–163 (1998). https://doi.org/10.1007/s100190050078

Issue Date:

DOI: https://doi.org/10.1007/s100190050078