Abstract

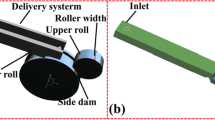

The production of thin aluminium-steel clad strips by means of twin-roll casting is one of the prospective trends in the development of sheet production. The main advantages of twin-roll casting are low specific energy and resource consumption. Besides this, the resulting compound has a high bonding strength owing to the presence of a continuous thin layer of intermetallic phases having an approximate thickness of 3 µm at the interface of the two metals. At the same time, the quality of the clad strip depends on the microstructure and properties of the aluminium layer formed directly from a melt. A deformation immediately following the solidification of the metal between the two rotated, internally water-cooled rolls has a substantial influence on this aluminium layer. Due to the complexity of observing the processes occurring in the melt pool, a numerical simulation became one of the main methods for their investigation. Simulation is widely used to describe the process of twin-roll casting of monomaterial strips, but so far it has not been used for to comprehensively analyse the process of twin-roll casting of clad strips. In the present paper, a two-dimentional finite-element simulation of the system “clad strip—water-cooled rolls” using the ANSYS software is proposed. A joint analysis is carried out of the heat transfer, viscous flow of aluminium melt, its solidification and deformation resulting in the temperature distribution in the cast metal as well as in the tool. The dependences of the deformation strain and outlet temperature of the clad strip on the main technological process parameters; obtained by numerical simulation, are shown.

Zusammenfassung

Die Herstellung von dünnen Aluminium-Stahl-Verbundbändern mittels des Zwei-Rollen-Gießverfahrens ist einer der Trends in der zukünftigen Entwicklung der Blechproduktion. Die wesentlichen Vorteile des Zwei-Rollen-Bandgießens sind geringe spezifische Energie-und Ressourcenverbräuche. Die mit dem Verfahren erzeugten Verbunde haben eine hohe Haftfestigkeit aufgrund der Entstehung auf der Kontaktfläche zwischen beiden Materialien einer kontinuierlichen dünnen Schicht von intermetallischen Phasen mit einer Dicke von ca 3 µm. Die Qualität der plattierten Bänder hängt von den Eigenschaften der dickeren Aluminiumschicht ab, die sich direkt aus der Schmelze bildet. Der entscheidende Einfluss auf die Mikrostruktur des Aluminiums hat die Umformung des gerade erstarrten Metalls zwischen den zwei rotierenden innenwassergekühlten Gießrollen. Da eine direkte Beobachtung des Prozessverlaufs zu komplex ist, hat sich die numerische Simulation zu einer Hauptmethode zur Erstarrungszonenanalyse entwickelt. Die Simulation wird häufig verwendet, um den Prozess des Bandgießens von Monometallen zu beschreiben, bisher jedoch nicht für eine umfassende Prozessanalyse zur Herstellung von Verbundbändern. In der vorliegenden Arbeit wird die zweidimensionale Finite-Elemente Simulation eines Systems „Verbundband – wassergekühlten Walzen“ mittels ANSYS Software vorgestellt. Es wird eine gemeinsame Analyse der Wärmeübertragung, des viskosen Werkstofffließens, der Erstarrung und Umformung des Aluminiums vorgenommen. Aus der numerischen Simulation resultieren die Temperaturverteilungen im Verbundband sowie im Werkzeug. Die mittels der FE-Analyse ermittelten Abhängigkeiten des Umformgrades und der Austrittstemperatur des Verbundbands von den wichtigsten technologischen Prozessparametern sind hier präsentiert worden.

Similar content being viewed by others

Abbreviations

- a 1–10 :

-

Regression equation coefficients [−]

- D :

-

Roll diameter [mm]

- H :

-

Resulting clad strip thickness [mm]

- H 0 :

-

Clad strip thickness prior to deformation in mold [mm]

- H s :

-

Steel strip thickness [mm]

- h :

-

Specific clad strip thickness [−]

- h al :

-

Specific aluminium layer thickness [−]

- h s :

-

Specific steel layer thickness [−]

- L d :

-

Deformation zone length [mm]

- L s :

-

Solidification zone length [mm]

- L t :

-

Total pool length [mm]

- l d :

-

Specific deformation zone length [−]

- l t :

-

Specific melt pool length [−]

- R :

-

Roll radii [mm]

- T :

-

Melt inlet temperature [°C]

- V :

-

Casting speed [m/min]

- α :

-

Pool contact angle [Rad]

- ε :

-

Plastic strain [%]

References

Stahl-Alu-Hybrid-platine ist serienreif (2011) Blech Rohre Profile 1–2:8

Haga T, Nakamura R, Kumai S, Watari H (2009) Clad strip casting by a twin roll caster. Mater Sci Eng 37:117–124

Bae JH, Rao AKP, Kim KH, Kim NJ (2011) Cladding of Mg alloy with Al by twin-roll casting. Scripta Materialia 64:836–839

Grydin O, Gerstein G, Nürnberger F, Schaper M, Danchenko V (2013) Twin-roll casting of aluminium–steel clad strips. J Manuf Process 15:501–507

Kawase BH, Makimoto M, Takagi K, Ishida Y, Tanaka T (1983) Development of aluminium-clad steel sheet by roll-bonding. Transactions ISIJ 23:628–632

Schloegl CM, Planitzer C, Harrer O, Buchmayr B (2011) Herstellung und Umformbarkeit walzplattierter Magnesium (AZ31)—Aluminium (1050)—Verbunde. BHM 156(7):249–254. doi:10.1007/s00501-011-0003-6

Grydin O, Schaper M, Danchenko V (2011) Twin-roll casting of high-strength age-hardened aluminium alloys. Metall Min Ind 3(7):7–16

Zhou SX, Zhong J, Mao D, Funke P (2003) Experimental study on material properties of hot rolled and continuously cast aluminium strips in cold rolling. JOMPT 134:363–373

Manesh HD, Taheri AK (2003) Bond strength and formability of an aluminum-clad steel sheet. J Alloy Compd 361:138–143

Mukae S, Nishio K, Kato M, Inoue T, Sumitomo K (1995) Effect of heat treatment on bond characteristics of aluminium clad steel: Production and characteristics of vacuum roll bonded clad materials. Weld Int 9(5):384–389

Ferry M (2006) Direct strip casting of metals and alloys. Woodhead Publishing Limited, Cambridge

Yun M et al (1991) An experimental investigation of the effect of strip thickness, metallostatic head and tip setback on the productivity of a twin-roll caster. Cast Metals IV(2):108–111

Yun M, Lokyer S, Hunt JD (2000) Twin roll casting of aluminium alloys. Mater Sci Eng A 280:116–123

Westengen H, Nes E (1984) Twin-roll casting of aluminium, The occurrence of structure, Inhomogeneities and defects in As-Cast strips. Light Metals. TMS Proceedings: 1111–1127

Cruchaga MA, Celentano DJ, Lewis RW (2003) Modelling of twin-roll strip casting processes. Commun Numer Meth Engng 19:623–635

Bae JW, Kang CG, Kang SB (2007) Mathematical model for the twin roll type strip continuous casting of magnesium alloy considering thermal flow phenomena. JOMPT 191:251–255

Cao GM, Li ZY, Liu ZY, Wu D, Wang GD, Liu XH (2008) Numerical simulation of molten pool and control strategy of kiss point in a twin-roll strip casting process. Acta metallurgica sinica 21(6):459–468

Gjerkeš H, Hartman S, Vertnik R, Šarler B (2007) Temperature field at the twin-roll casting of aluminium alloys: computational model and measurements. WIT Trans Modelling Simul 46:35–44

Zhao H, Li P, He L (2011) Coupled analysis of temperature and flow during twin-roll casting of magnesium alloy strip. JMPT 211:1197–1202

Miehe A, Gross U (2012) Modelling of heat transfer and solidification processes in horizontal TRC of magnesium alloy AZ31. IOP Conf. Series: Mater Sci Eng 33:12–17. doi:10.1088/1757-899X/33/1/012017

Saxena A, Sahai Y (2002) Modeling of fluid flow and heat transfer in twin roll casting of aluminium alloys. Mater Trans 43(2):206–213

Sarioglu K, Thevoz P (2003) Simulation of solidification process used in twin roll casting. Light metals. TMS Warrendale Proceedings: 747–752

Hazadzadeh A, Wells M, Essadiqi E (2012) Mathematical modeling of the twin roll casting process for AZ31 magnesium alloy—effect on the strip thickness. Mg2012: 9th International Conference on Magnesium Alloys and their Applications: 177–182

Ju DY, Hu XD, Zhao HY (2009) Inelastic behavior and numerical analysis in twin-roll casting process of AZ31 alloy. Arch Mech Warszawa 61(3–4):229–239

Hu XD, Ju DY, Zhao HY (2012) Thermal flow simulation of twin-roll casting magnesium alloy. J Shanghai Jiaotong Univ (Sci) 17(4):479–483. doi:10.1007/s12204-012-1309-6

Liu L et al (2014) 3D numerical simulation on thermal flow coupling field of stainless steel during twin-roll casting. JMEPEG 23:39–48. doi:10.1007/s11665-013-0749-y

Fang Y et al (2009) Numerical simulation of the temperature fields of stainless steel with different roller parameters during twin-roll strip casting. Int J Min Metall Mater 16(3):304–308

Sahoo S, Kumar A, Dhindaw BK, Ghosh S (2013) Modeling and experimental validation of rapid cooling and solidification during high-speed twin-roll strip casting of Al-33 wt pct Cu. Metall Mater Trans B 4(43):915–924

Stolbchenko M (2013) The influence of initial temperature and rolling speed on the deformation parameters at the twin-roll casting of high-strength aluminium-alloyed strips. Materials working by pressure 3(36):173–179

Grydin O, Ogins’kyy Y, Danchenko V, Bach FW (2010) Experimental twin-roll casting equipment for production of thin strips. Metall Min Ind 2(5):348–354

Bondarenko S, Grydin O, Stolbchenko M, Schaper M (2013) Determination of the heat transfer coefficient in the metal-roll system at twin-roll casting of aluminium alloys. Metal Cast Ukraine 5:3–8

Guthrie RIL, Isac M, Kim JS, Tavares RP (2000) Measurements, simulations, and analyses of instantaneous heat fluxes from solidifying steels to the surfacesof twin roll casters and of aluminum to plasma-coated metal substrates. Metall Mater Trans B. Process Metallurgy and Materials Processing Science 31(5):1031–1047

Khvist V, Stolbchenko M, Grydin A, Samsonenko A, Golovko Ð (2013) Influence of temperature-rate modes of twin roll casting on the formation of bimetallic aluminium-steel bands in the twin-roll crystallizer. Materials working by pressure 3(36):180–184

Zeng J, Koitzsch R, Pfeifer H, Friedrich B (2009) Numerical simulation of the twin-roll casting process of magnesium alloy strip. JOMPT 209:2321–2328

Acknowledgments

The authors would like to thank the German Research Foundation (DFG) for their financial support for the work carried out here within the scope of the project SCHA 1484/21-1 “Manufacturing of the aluminium-steel compound by means of twin-roll casting”.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Stolbchenko, M., Grydin, O., Samsonenko, A. et al. Numerical analysis of the twin-roll casting of thin aluminium-steel clad strips. Forsch Ingenieurwes 78, 121–130 (2014). https://doi.org/10.1007/s10010-014-0182-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10010-014-0182-x