Abstract

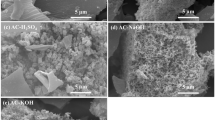

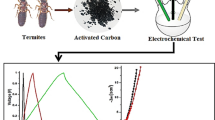

The cost-effective activated carbon based from waste cotton stalks by the KOH activation method is investigated as the electrode material in supercapacitor for the first time. Activation temperature control is one of the most important factors affecting the surface area and pore structure of activated carbon, and it influences the capacitive performance of activated carbon based from cotton stalk. The optimized conditions are as follows: cotton stalk base charcoals and activating agent with a mass ration of 1:4, at an activation temperature of 600, 700, and 800°C for 1, 1, and 2 h, respectively. With these experimental conditions, the activated carbon presents excellent electrochemical characteristics. The specific capacitance of the prepared activated carbon was as high as 180 F g−1at 2 A g−1 in 1.0 mol·L−1 Et4NBF4/AN electrolyte and the specific capacitance without obvious attenuation after 2000 cycles. So, it is reasonable to believe that the activated carbons from cotton stalks by the KOH gradient constant temperature activation method might be one of the innovative carbon electrode materials for supercapacitor.

Similar content being viewed by others

References

Qua QT, Shia Y, Tiana S, Chena YH, Wua YP, Holzeb R (2009) J Power Sources 194:1222–1226

Wu YP, Dai XB, Ma JQ, Cheng YJ (2004) Lithium ion batteries—practice & applications. Chemical Industry Press, Beijing

Xing W, Qiao SZ, Ding RG, Li F, Lu GQ, Yan ZF (2006) Carbon 44:216–224

Lota G, Centeno TA, Frackowiak E, Stoeckli F (2008) Electrochim Acta 53:2210–2216

Bentley P, Stone DA, Schofield N (2005) J Power Sources 147:288–294

Zhang JT, Gong LY, Kang S, Jiang JC, Zhang XG (2012) J Solid State Electrochem 16:2179–2186

Liang HC, Chen F, Li RG, Wang L, Deng ZH (2004) Electrochim Acta 49:3463–3467

Iijima S (1991) Nature 354:56–58

Gao B, Hao L, Fu QB, Su LH, Yuan CZ, Zhang XG (2010) Electrochim Acta 55:3681–3686

Pekala RW (1988) Stone RE. Polymer preprint 29:204–206

Pekala RW (1989) J Material Science 24:3221–3227

Du X, Guo P, Song HH, Chen XH (2010) Electrochim Acta 55:4812–4819

Zhang LL, Zhou R, Zhao XS (2010) J Mater Chem 20:5983–5992

Liu YF, Hu ZH, Xu K, Zheng XW, Qiang G (2008) Acta Phys. Chim Sin 24:1143–1148

Ahmadpour A, Do DD (1997) Carbon 35:1723–1732

Subramanian V, Luo C, Stephan AM, Nahm KS, Thomas S, Wei BJ (2007) J Phys Chem C 111:7527–7531

Wu FC, Tseng RL, Hu CC, Wang CC (2004) J Power Sources 138:351–359

Wu FC, Tseng RL, Hu CC, Wang CC (2005) J Power Sources 144:302–309

Balathanigaimani MS, Wang GS, Lee MJ, Chan K, Lee JW, Hee M (2008) Electrochem Commun 8:868–871

Wang XF, Tian Y (2010) Int Mater Rev 24:21–27

Guo YP, Qi JR, Jiang YQ, Yang SF, Wang ZC, Xu HD (2003) Mater Chem Phys 80:704–709

Li X, Xing W, Zhuo SJ, Qiao SZ, Lu GQ (2011) Bioresour Technol 102:1118–1123

Olivares-Marína M, Fernández JA, Lázaro MJ, Fernández-González C, Macías-García A, Gómez-Serrano V, Stoeckli F, Centenob TA (2009) Mater Chem Phys 114:323–327

Ma YW, Xiong CY, Huang W, Zhao J, Li XA, Fan QL, Huang W (2012) Chinese J Inorg Chem 28:546–550

Akdeniz RC, Acaroglu M, Arif H (2004) Energ Source 26:65–75

Deng H, Zhang GL, Xu XL, Tao GH, Dai JL (2010) J Hazardous Materials 182:217–224

Ahmadpour A, Do DD (1996) Carbon 34:471–479

Armandi MB, Bonelli F (2010) Geobaldo, Garrone E. Micropor Mesopor Mater 132:414–420

Deng H, Li G, Yang H, Tang J (2010) Chem Eng J 163:373–381

Ioannidou O, Zabaniotou A (2007) Renewable and Sustainable Energy Reviews11:1966–2005

Akdeniz RC, Acaroglu M, Arif H (2004) Energ Source 26:65–75

Prahas D, Kartika Y, Indraswatin N (2008) Chem Eng J 140:32–42

Stoeckli HF (1990) Carbon 28:1–6

Andrian EI, Steven W (2010) Bioresour Technol 101:3534–3540

Choy KKH, Barford JP, McKay G (2005) Chin J Chem Eng 109:147–165

Ganan J, González-Garcia CM, Gonzáleza JF, Sabioa E, Macias-Garciab A, Diaz-Diez MA (2004) Appl Surf Sci 238:347–354

Daud WMAW, Ali WSW (2004) Bioresour Technol 93:63–69

Marsh H, Rodriguez-Reinoso F (2006 ) Activated carbon (Elsevier), pp 322–365

Lillo-Ródenas MA, Juan-Juan J, Cazorla-Amoros D, Linares-Solano A (2004) Carbon 42:1371–1375

Li W, Zhang LB, Peng JH, Li N, Zhu XY (2008) Ind Crop Prod 27:341–347

Barsoukov E, Macdonald JR (2005) Impedance spectroscopy: theory, experiment, and applications. Hoboken, NJ, pp. 478–479

Zhou J, Xing W, Zhuo SP, Zhao Y (2011) Solid State Sci 13:2000–2006

Acknowledgments

The authors are grateful for support from Advanced Carbon Materials Research Laboratory, College of Materials Science and Engineering, Beijing University of Chemical Technology.

This work was supported by the Xinjiang science and technology aid project in Xinjiang (No.2013911049), Industrial Science and technology project of Shaanxi Province (NO.2016GY-170), the “West Light” Talents Cultivation Program of the Chinese Academy of Sciences (No.XBBS200919), and the Foundation of State Key Laboratory of Chemical Resource Engineering (BUCT).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Li, W., Wumaier, T., Chen, M. et al. Effect of the gradient constant temperature on the electrochemical capacitance of cotton stalk-based activated carbon. J Solid State Electrochem 20, 2315–2321 (2016). https://doi.org/10.1007/s10008-016-3235-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-016-3235-2