Abstract

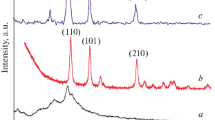

Polyaniline–tin dioxide (PANI-SnO2) composites were prepared by chemical polymerization method, and characterized by scanning electron microscopy, transmission electron microscopy, Fourier transform infrared spectroscopy, and X-ray diffraction. Due to the good stability in diluted acidic solution, PANI-SnO2 composites were selected as the catalyst support and second catalyst for methanol electro-oxidation. The electrocatalytic properties of the PANI-SnO2 supported Pt catalyst (Pt/PANI-SnO2) for methanol oxidation have been investigated by cyclic voltammetry, chronoamperometry, and chronopotentiometry. Under the same loading mass of Pt, the Pt/PANI-SnO2 catalyst shows higher electrocatalytic activity towards methanol electro-oxidation than Pt/SnO2 catalyst.

Similar content being viewed by others

References

Antolini E, Salgado JRC, Gonzalez ER (2005) J Electroanal Chem 580:145

Lin YH, Cui XL, Yen C, Wai CM (2005) J Phys Chem B 109:14410

Wang JS, Xi JY, Bai YX, Shen Y, Sun J, Chen LQ, Zhu WT, Qiu XP (2007) J Power Sources 102:172

Paulus UA, Endruschat U, Feldmeyer GJ, Schmidt TJ, Bonnemann H, Behm RJ (2000) J Catal 195:383

Jayaraman S, Jaramillo TF, Baeck S-H, McFarland EW (2005) J Phys Chem B 109:22958

Shim J, Lee C, Lee H, Cairns EJ (2001) J Power Sources 102:172

Campos CL, Roldán C, Aponte M, Ishikawa Y, Carbrera CR (2005) J Electroanal Chem 581:206

Xu C, Shen PK (2004) Chem Commun 19:2238

Villullas HM, Mattos-Costa FI, Bulhǒes LOS (2004) J Phys Chem B 108:12898

Grass K, Lintz H-G (1997) J Catal 172:446

Gangal ND, Gupta NM, Iyer RM (1990) J Catal 126:13

Matsui T, Fujiwara K, Okanishi T, Kikuchi R, Takeguchi T, Eguchi K (2006) J Power Sources 155:152

Kawabe T, Tabata K, Suzuki E, Nagasawa Y (2001) Surf Sci 482–485:183

Santos AL, Profeti D, Olivi P (2005) Electrochim Acta 50:2615

Dimov N, Kugino S, Yoshio M (2003) Electrochim Acta 48:1579

Chen WX, Lee JY, Liu Z (2002) Electrochem Commun 4:260

Poizot P, Laruelle S, Grugeon S, Dupont L, Tarascon JM (2000) Nature 407:496

Lamy C, Leger J-M, Garnier F (1997) In: Nalwa HS (ed) Handbook of organic conductive molecules and polymer. Wiley, New York, p 471 3

Rajendra Prasad K, Munichandraiah N (2002) J Power Sources 103:300

Skothemin T, Elsenbaumer R (1998) Handbook of conductive polymers. Marcel Dekker, New York

Kim S, Park SJ (2008) Solid State Ion 178:1915

Dutta K, De SK (2007) Mater Lett 61:4967

Geng LN, Zhao YQ, Huang XL, Wang SR, Zhang SM, Wu SH (2007) Sens Actuators B 120:568

Hu ZA, Xie LY, Wang YX, Mo LP, Yang YY, Zhang ZY (2009) Mater Chem Phys 114:990

Pang HL, Lu JP, Chen JH, Huang CT, Liu B, Zhang XH (2009) Electrochim Acta 54:2610

Xia HS, Wang Q (2002) Chem Mater 14:2158

He YJ (2005) Mater Chem 43:2892

Geng LN, Zhao YQ, Huang XL, Wang SR, Zahng SM, Wu SH (2007) Sens Actuators B 120:568

Pozio A, Francesco MD, Cemmi A, Cardellini F, Giorgi L (2002) J Power Sources 105:13

Li WS, Lu J, Du JH, Lu DS, Chen HY, Li H, Wu YM (2005) Electrochem Commun 7:406

Xu C, Shen PK (2005) J Power Sources 142:27

Acknowledgements

This work is supported by Program for New Century Excellent Talents in University (NCET-04-0765), National Natural Science Foundation of China (50172014, 20675027), and Scientific Research Foundation for the Returned Overseas Chinese Scholars, State Education Ministry (2001-498).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pang, H., Huang, C., Chen, J. et al. Preparation of polyaniline–tin dioxide composites and their application in methanol electro-oxidation. J Solid State Electrochem 14, 169–174 (2010). https://doi.org/10.1007/s10008-009-0892-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-009-0892-4