Abstract

Background

To increase the range of motion of total hip endoprostheses, prosthetic heads need to be enlarged, which implies that the cup and/or liner thickness must decrease. This may have negative effects on the wear rate, because the acetabular cups and liners could deform during press-fit implantation and hip joint loading. We compared the metal cup and polyethylene liner deformations that occurred when different wall thicknesses were used in order to evaluate the resulting changes in the clearance of the articulating region.

Methods

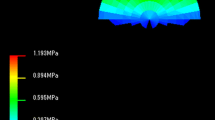

A parametric finite element model utilized three cup and liner wall thicknesses to analyze cup and liner deformations after press-fit implantation into the pelvic bone. The resultant hip joint force during heel strike was applied while the femur was fixed, accounting for physiological muscle forces. The deformation behavior of the liner under joint loading was therefore assessed as a function of the head diameter and the resulting clearance.

Results

Press-fit implantation showed diametral cup deformations of 0.096, 0.034, and 0.014 mm for cup wall thicknesses of 3, 5, and 7 mm, respectively. The largest deformations (average 0.084 ± 0.003 mm) of liners with thicknesses of 4, 6, and 8 mm occurred with the smallest cup wall thickness (3 mm). The smallest liner deformation (0.011 mm) was obtained with largest cup and liner wall thicknesses. Under joint loading, liner deformations in thin-walled acetabular cups (3 mm) reduced the initial clearance by about 50 %.

Conclusion

Acetabular press-fit cups with wall thicknesses of ≤5 mm should only be used in combination with polyethylene liners >6 mm thick in order to minimize the reduction in clearance.

Similar content being viewed by others

References

Krukemeyer M, Möllenhoff G. Endoprothetik. Leitfäden für Praktiker. Berlin: de Gruyter; 2009.

Widmer KH, Zurfluh B, Morscher EW. Load transfer and fixation mode of press-fit acetabular sockets. J Arthroplast. 2002;17(7):926–35.

Maloney WJ. Orthopaedic crossfire—larger femoral heads: a triumph of hope over reason! In opposition. J Arthroplast. 2003;18(3 Suppl 1):85–7.

Hermida JC, Bergula A, Chen P, Colwell CW Jr, D’Lima DD. Comparison of the wear rates of twenty-eight and thirty-two-millimeter femoral heads on cross-linked polyethylene acetabular cups in a wear simulator. J Bone Joint Surg Am. 2003;85-A(12):2325–31.

Kluess D, Martin H, Mittelmeier W, Schmitz KP, Bader R. Influence of femoral head size on impingement, dislocation and stress distribution in total hip replacement. Med Eng Phys. 2007;29(4):465–71.

Teoh SH, Chan WH, Thampuran R. An elasto-plastic finite element model for polyethylene wear in total hip arthroplasty. J Biomech. 2002;35(3):323–30.

Ong KL, Rundell S, Liepins I, Laurent R, Markel D, Kurtz SM. Biomechanical modeling of acetabular component polyethylene stresses, fracture risk, and wear rate following press-fit implantation. J Orthop Res. 2009;27(11):1467–72.

Mai MT, Schmalzried TP, Dorey FJ, Campbell PA, Amstutz HC. The contribution of frictional torque to loosening at the cement–bone interface in Tharies hip replacements. J Bone Joint Surg Am. 1996;78(4):505–11.

Hamilton WG, Calendine CL, Beykirch SE, Hopper RH Jr, Engh CA. Acetabular fixation options: first-generation modular cup curtain calls and caveats. J Arthroplast. 2007;22(4 Suppl 1):75–81.

Jin ZM, Meakins S, Morlock MM, Parsons P, Hardaker C, Flett M, Isaac G. Deformation of press-fitted metallic resurfacing cups. Part 1: experimental simulation. Proc Inst Mech Eng H. 2006;220(2):299–309.

Schmidig G, Patel A, Liepins I, Thakore M, Markel DC. The effects of acetabular shell deformation and liner thickness on frictional torque in ultrahigh-molecular-weight polyethylene acetabular bearings. J Arthroplast. 2010;25(4):644–53.

Yew A, Jin ZM, Donn A, Morlock MM, Isaac G. Deformation of press-fitted metallic resurfacing cups. Part 2: finite element simulation. Proc Inst Mech Eng H. 2006;220(2):311–9.

Fritsche A, Bialek K, Mittelmeier W, Simnacher M, Fethke K, Wree A, Bader R. Experimental investigations of the insertion and deformation behavior of press-fit and threaded acetabular cups for total hip replacement. J Orthop Sci. 2008;13(3):240–7.

Crowninshield RD, Maloney WJ, Wentz DH, Humphrey SM, Blanchard CR. Biomechanics of large femoral heads: what they do and don’t do. Clin Orthop Relat Res. 2004;429:102–7.

Bergmann G, Deuretzbacher G, Heller M, Graichen F, Rohlmann A, Strauss J, Duda GN. Hip contact forces and gait patterns from routine activities. J Biomech. 2001;34(7):859–71.

Dalstra M, Huiskes R, van Erning L. Development and validation of a three-dimensional finite element model of the pelvic bone. J Biomech Eng. 1995;117(3):272–8.

Garcia JM, Doblare M, Seral B, Seral F, Palanca D, Gracia L. Three-dimensional finite element analysis of several internal and external pelvis fixations. J Biomech Eng. 2000;122(5):516–22.

ASTM International. ASTM-D695. Standard test method for compressive properties of rigid plastics. West Conshohocken: ASTM International; 2010.

ASTM International. ASTM-D1621. Standard test method for compressive properties of rigid cellular plastics. West Conshohocken: ASTM International; 2010.

Zhang C, Leng Y, Chen J. Elastic and plastic behavior of plasma-sprayed hydroxyapatite coatings on a Ti-6Al-4V substrate. Biomaterials. 2001;22(11):1357–63.

Burger W, Richter HG. High strength and toughness alumina matrix composites by transformation toughening and “in situ” platelet reinforcement (ZPTA)—the new generation of bioceramic. Bioceramics. 2001;13:545–8.

Kluess D, Souffrant R, Mittelmeier W, Wree A, Schmitz KP, Bader R. A convenient approach for finite-element-analyses of orthopaedic implants in bone contact: modeling and experimental validation. Comput Methods Programs Biomed. 2009;95(1):23–30.

Speirs AD, Heller MO, Duda GN, Taylor WR. Physiologically based boundary conditions in finite element modelling. J Biomech. 2007;40(10):2318–23.

Heller MO, Bergmann G, Kassi JP, Claes L, Haas NP, Duda GN. Determination of muscle loading at the hip joint for use in pre-clinical testing. J Biomech. 2005;38(5):1155–63.

Heiner AD. Structural properties of fourth-generation composite femurs and tibias. J Biomech. 2008;41(15):3282–4.

Kim JE, Li Z, Ito Y, Huber CD, Shih AM, Eberhardt AW, Yang KH, King AI, Soni BK. Finite element model development of a child pelvis with optimization-based material identification. J Biomech. 2009;42(13):2191–5.

Polgar K, Viceconti M, O’Connor JJ. A comparison between automatically generated linear and parabolic tetrahedra when used to mesh a human femur. Proc Inst Mech Eng H. 2001;215(1):85–94.

Jin ZM, Dowson D, Fisher J. Analysis of fluid film lubrication in artificial hip joint replacements with surfaces of high elastic modulus. Proc Inst Mech Eng H. 1997;211(3):247–56.

Wang A, Essner A, Klein R. Effect of contact stress on friction and wear of ultra-high molecular weight polyethylene in total hip replacement. Proc Inst Mech Eng H. 2001;215(2):133–9.

Bader R, Scholz R, Steinhauser E, Zimmermann S, Busch R, Mittelmeier W. The influence of head and neck geometry on stability of total hip replacement: a mechanical test study. Acta Orthop Scand. 2004;75(4):415–21.

Waewsawangwong W, Goodman SB. Unexpected failure of highly cross-linked polyethylene acetabular liner. J Arthroplast. 2012;27(2):323.e1–4.

Tower SS, Currier JH, Currier BH, Lyford KA, Van Citters DW, Mayor MB. Rim cracking of the cross-linked longevity polyethylene acetabular liner after total hip arthroplasty. J Bone Joint Surg Am. 2007;89(10):2212–7.

Acknowledgments

The authors would like to thank OHST Medizintechnik AG, 14712 Rathenow, Germany, for technical support.

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Goebel, P., Kluess, D., Wieding, J. et al. The influence of head diameter and wall thickness on deformations of metallic acetabular press-fit cups and UHMWPE liners: a finite element analysis. J Orthop Sci 18, 264–270 (2013). https://doi.org/10.1007/s00776-012-0340-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00776-012-0340-7