Abstract

It is known that the unconfined compressive strength of rock decreases with increasing density of geological features such as micro-cracks, fractures, and veins both at the laboratory specimen and rock block scales. This article deals with the confined peak strength of laboratory-scale rock specimens containing grain-scale strength dominating features such as micro-cracks. A grain-based distinct element model, whereby the rock is simulated with grains that are allowed to deform and break, is used to investigate the influence of the density of cracks on the rock strength under unconfined and confined conditions. A grain-based specimen calibrated to the unconfined and confined strengths of intact and heat-treated Wombeyan marble is used to simulate rock specimens with varying crack densities. It is demonstrated how such cracks affect the peak strength, stress–strain curve and failure mode with increasing confinement. The results of numerical simulations in terms of unconfined and confined peak strengths are used to develop semi-empirical relations that relate the difference in strength between the intact and crack-damaged rocks to the confining pressure. It is shown how these relations can be used to estimate the confined peak strength of a rock with micro-cracks when the unconfined and confined strengths of the intact rock and the unconfined strength of the crack-damaged rock are known. This approach for estimating the confined strength of crack-damaged rock specimens, called strength degradation approach, is then verified by application to published laboratory triaxial test data.

Similar content being viewed by others

Notes

Definitions and adopted terminologies used in this article, such as intact rock, micro-crack, and strength degradation are provided in the “Appendix.”

UCS i and UCS d stand for unconfined compressive strength of intact rock and rock with micro-cracks, respectively (see “Appendix” for definition).

SJ f = 0 % refers to a grain-based specimen where all the smooth-joint contacts are cohesive, and SJ f = 100 % refers to a grain-based specimen where all the smooth-joint contacts are frictional.

References

Bahrani N, Kaiser PK (2013) Strength degradation of non-persistently jointed rock mass. Int J Rock Mech Min Sci 62:28–33

Bahrani N, Kaiser PK, Valley B (2014) Distinct element method simulation of an analogue for a highly interlocked, non-persistently jointed rock mass. Int J Rock Mech Min Sci 71:117–130

Brady BHG, Brown ET (2007) Rock mechanics for underground mining. Kluwer Academic Publishers, The Netherlands

Diederichs MS (2003) Manuel Rocha medal recipient: rock fracture and collapse under low confinement conditions. Rock Mech Rock Eng 36(5):339–381

Eberhardt E, Stead D, Stimpson B (1999) Effects of sample disturbance on the stress-induced microfracturing characteristics of brittle rock. Can Geotech J 36:239–250

Fang Z, Harrison JP (2001) A mechanical degradation index for rock. Int J Rock Mech Min Sci 38:1193–1199

Gerogiannopoulos NG (1976) A critical state approach to rock mechanics. PhD thesis, University of London

Griffith AA (1921) The phenomena of rupture and flow in solids. Philos Trans R Soc Lond A 221:163–198

Hoek E, Bieniawski ZT (1965) Brittle rock fracture propagation in rock under compression. Int J Fract Mech 1:137–155

Hoek E, Brown ET (1980) Underground excavations in rock. Institution of mining and metallurgy, London

Hoek E, Brown ET (1997) Practical estimates of rock mass strength. Int J Rock Mech Min Sci 34(8):1165–1186

Holt RM, Brignoli M, Kenter CJ (2000) Core quality: quantification of coring-induced rock alteration. Int J Rock Mech Min Sci 37:889–907

Itasca (2008) Particle flow code in 2 dimensions (PFC2D), Ver. 4.0. Itasca Consulting Group Inc, Minneapolis

Kaiser PK, Kim B (2015) Characterization of strength of intact brittle rock considering confinement-dependent failure processes. Rock Mech Rock Eng 48(1):107–119

Lanaro F, Sato T, Nakama S (2009) Depth variability of compressive strength test results of Toki granite from Shobasama and Mizunami Construction Sites, Japan. Rock Mech Rock Eng 42:611–629

Martin C (1993) The strength of massive Lac du Bonnet granite around underground openings. PhD thesis, University of Manitoba

Martin CD, Stimpson B (1994) The effect of sample disturbance on laboratory properties of Lac du Bonnet granite. Can Geotech J 31:692–702

Patton FD (1966) Multiple mode of shear failure in rock. In: 1st international conference Rock Mech, Lisbon, pp 509–511

Potyondy DO (2010) A grain-based model for rock: approaching the true microstructure. In: Proceeding of Rock Mech in the Nordic Countries

Potyondy DO, Cundall PA (2004) A bonded particle model for rock. Int J Rock Mech Min Sci 41:1329–1364

Rosengren KJ, Jaeger JC (1968) The mechanical properties of an interlocked low-porosity aggregate. Géotechnique 18:317–326

Watson BP, Kuijpers JS, Henry G, Palmer CE, Ryder JA (2009) Nonlinear rock behaviour and its implications for deeper level platinum mining. J South Afr Inst Min Metall 108:5–13

Acknowledgments

This research project was supported by the Natural Sciences and Engineering Research Council of Canada (NSERC), the Centre for Excellence in Mining Innovation (CEMI) through the Smart Underground Monitoring and Integrated Technologies (SUMIT) program lead by Laurentian University, and the Itasca Consulting Group through its Itasca Education Partnership (IEP) program. The authors would like to acknowledge Nezam Bozorgzadeh from University of Toronto for insightful discussions about the statistical concepts and approach used in this article.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

This Appendix summarizes the terminologies adopted in this article.

1.1 Intact Rock

Intact rock is used to describe the homogeneous portion of a rock, the material between geological features, which might be represented by a hand specimen or piece of drill core examined in the laboratory (Brady and Brown 2007). In this article, intact rock refers specifically to a laboratory specimen that does not contain any strength dominating features such as micro-cracks, fractures, veins, or cemented joints.

1.2 Micro-cracks

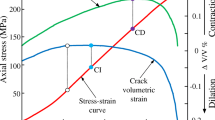

Micro-cracks are noncohesive flaws at the grain scale such as grain and grain boundary cracks, which may influence the strength and/or failure mode of rocks under different stress conditions.

1.3 UCS i and UCS d

UCS stands for unconfined compressive strength. The value of UCS is directly obtained from the laboratory unconfined compression test. In this article, UCS i and UCS d are used to describe the unconfined compressive strength of “intact” rock and rock specimens with micro-cracks, respectively.

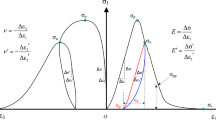

1.4 UCS i and σ ci

UCS i is the unconfined compressive strength obtained directly from laboratory tests on unconfined intact rock specimens. As per recommendation by Hoek and Brown (1997), σ ci is determined by extrapolation, from fitting triaxial test data covering a confinement range up to half of UCS i in five equal increments, to the unconfined state; it is obtained by back projection using a least-square regression analysis. Studies by Kaiser and Kim (2015) have shown that independently determined unconfined strengths from UCS tests and from triaxial tests (σ ci ) on the same rock type do not correspond; UCS i is often lower than σ ci . Thus, UCS data should not be used as a replacement for σ ci .

1.5 Strength Degradation

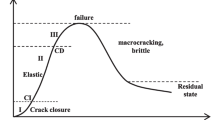

The term “degradation” in rock mechanics is used for different purposes. For example, Fang and Harrison (2001) used the term “degradation” to describe the post-peak strength reduction. In this article, the difference between the peak strengths of intact rock and rock containing micro-cracks (or the peak strength reduction due to micro-cracks) is called “rock strength degradation.” The concept of strength degradation is schematically shown in Fig. 16. Figure 16a illustrates a situation where the strength of a rock with micro-cracks increases rapidly with increasing confinement and approaches the intact strength. Therefore, the strength degradation (∆σ 1), which is the strength difference between the intact rock (σ 1i ) and the rock with micro-cracks (σ 1d ), decreases rapidly with increasing confinement and remains almost constant beyond a critical confining pressure (Fig. 16b).

According to Bahrani and Kaiser (2013), this critical confining pressure is between UCS i /20 and UCS i /6, with a typical central value of UCS i /10, as was suggested by Kaiser and Kim (2015). The rapid increase in the strength of rocks containing micro-cracks with confinement is due to the reduction in the length of propagating cracks and a resistance of an interlocked structure to dilation. When the confining pressure is greater than about 10 % of the applied axial stress, (σ 1/σ 3 > 0.1; Hoek and Bieniawski 1965; Diederichs 2003) shear banding or shear rupture starts and eventually dominates the confined rock failure process.

Rights and permissions

About this article

Cite this article

Bahrani, N., Kaiser, P.K. Estimation of Confined Peak Strength of Crack-Damaged Rocks. Rock Mech Rock Eng 50, 309–326 (2017). https://doi.org/10.1007/s00603-016-1110-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-016-1110-1