Abstract

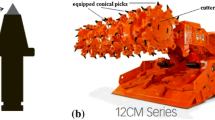

Conical pick is a widely used tool for cutting coal in mines. It has a cemented carbide tip inserted in a steel body. Cemented carbide has been in use for many years for coal/rock cutting because it has the optimum combination of hardness, toughness and resistance against abrasive wear. As coal/rock is a heterogeneous substance, the cutting tool has to undergo various obstructions at the time of excavation that cause the tool to wear out. The cracks and fractures developing in the cemented carbide limit the life of the tool. For a long time, different wear mechanisms have been studied to develop improved grades of cemented carbide with high wear resistance properties. The research is still continuing. Moreover, due to the highly unpredictable nature of coal/rock, it is not easy to understand the wear mechanisms. In the present work, an attempt has been made to understand the wear mechanisms in four conical picks, which were used in a continuous miner machine for underground mining of coal. The wearing pattern of the conical pick indicates damage in its cemented carbide tip as well as the steel body. The worn out parts of the tools have been critically examined using scanning electron microscopy (SEM) and energy dispersive X-ray (EDX) point analysis. Mainly four types of wear mechanisms, namely, coal/rock intermixing, plastic deformation, rock channel formation and crushing and cracking, have been detected. The presence of coal/rock material and their respective concentrations in the selected area of worn out surface were observed using the spectra generated by EDX analysis.

Similar content being viewed by others

References

Beste U, Jacobson S (2008) A new view of the deterioration and wear of WC/Co cemented carbide rock drill buttons. Wear 264:1129–1141

Bilgin N, Demircin MA, Copur H, Balci C, Tuncdemir H, Akcin N (2006) Dominant rock properties affecting the performance of conical picks and the comparison of some experimental and theoretical results. Int J Rock Mech Min Sci 43:139–156. doi:10.1016/j.ijrmms.2005.04.009

Bilgin N, Copur H, Balci C (2013) Mechanical excavation in mining and civil industries. CRC Press, Boca Raton, pp 103–123

Chiaia B, Borri-Brunetto M, Carpinteri A (2013) Mathematical modelling of the mechanics of core drilling in geomaterials. Mach Sci Technol 17:1–25. doi:10.1080/10910344.2012.747881

Daoush WM, Lee KH, Park HS, Hong SH (2009) Effect of liquid phase composition on the microstructure and properties of (W, Ti) C Cemented carbide cutting tools. Int J Refract Met Hard Mater 27:83–89

Deng X et al (2001) Mechanical properties of a hybrid cemented carbide composite. Int J Refract Met Hard Mater 19:547–552

Dixon G, Wright RN, Lee M (1985) Processes involved in the wear of cemented carbide tools. Wear 104(2):157–171

Glowka DA, Stone CM (1986) Effects of thermal and mechanical loading on PDC bit life. Drill Eng 1(3):201–214

Hurt KG, Evans I (1981) Point attack tools: an evaluation of function and use for rock cutting. Min Eng 140(234):673–675

Kenny P, Johnson SN (1976) The effect of wear on the performance of mineral-cutting tools. Colliery Guard 224(6):246–251

Khair AW (2001). Research and Innovations for Continuous Miner’s Cutting Head for Efficient Cutting process of rock/coal. Department of Mining Engineering, West Virginia University, Morgantown, USA. 17* International Mining Congress and Exhibition of Turkey- IMCET2001

Maidl B, Schmid L, Ritz W, Herrenknecht M (2008) Hard rock tunnel boring machines. Ernst & Sohn, Berlin

Miller MH, Sikarskie DL (1968) On the penetration of rock by three-dimensional indentors. Int J Rock Mech Min Sci 5:375–398

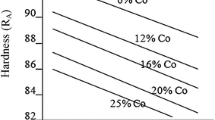

Milman YuV, Luyckx S, Northrop IT (1999) Influence of temperature, grain size and cobalt content on the hardness of WC–Co alloys. Int J Refract Met Hard Mater 17:39–44

Mishnaevsky LL (1995) Mathematical modeling of wear of cemented carbide tools in cutting brittle materials. Int J Mach Tools Manuf 35:717–724

Mukhopadhyay A, Basu B (2011) Recent developments on WC-based bulk composites. J Mater Sci 46:571–589

Olovsjo S, Johanson R, Falsafi F, Bexell U, Olsson M (2013) Surface failure and wear of cemented carbide rock drill buttons—the importance of sample preparation and optimized microscopy settings. Wear 302:1546–1554

Pirso J, Letunovits S, Viljus M (2004) Friction and wear behaviour of cemented carbides. Wear 257:257–265

Plis MN, Wingquist CF, Roepke WW (1988) Preliminary evaluation of the relationship of bit wear to cutting distance, forces and dust using selected commercial and experimental coal and rock cutting tools. USBM, RI-9193

Rajput RK (2007) A text book of Manufacturing technology: (Manufacturing processes), Firewall Media, (page-407)

Stolarski TA (2000) Tribology in machine design. Butterworth-Heinemann, Oxford

Upadhyaya GS (2001) Materials science of cemented carbides—an overview. Mater Des 22:483–489

Wood GA (1970) Quality control in the hard metal industry. Powder Metall 13:338–368

Yardley ED (1987) Wear resistant materials. Colliery Guardian 235(1):8–16

Yilmaz NG, Yurdakul M, Goktan RM (2007) Prediction of radial bit cutting force in high-strength rocks using multiple linear regression analysis. Int J Rock Mech Min Sci 44:962–970. doi:10.1016/j.ijrmms.2007.02.005

Zum Gahr KH (1987) Microstructure and wear of materials. Elsevier, Amsterdam

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dewangan, S., Chattopadhyaya, S. & Hloch, S. Wear Assessment of Conical Pick used in Coal Cutting Operation. Rock Mech Rock Eng 48, 2129–2139 (2015). https://doi.org/10.1007/s00603-014-0680-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-014-0680-z