Abstract

The cracked chevron-notched Brazilian disc (CCNBD) was proposed by the International Society for Rock Mechanics (ISRM) to test the mode I (opening mode) fracture toughness of rock. The test method has been vigorously discussed and debated, despite being the subject of intensive research for decades. The minimum (critical) dimensionless stress intensity factors affiliated with the formula for calculating the fracture toughness using CCNBD specimens with different geometric parameters remain elusive and complex. The matter cannot be resolved by simply replacing the diameter in the original formula with the radius, as claimed by several authors. In this paper, the formula is fundamentally improved, as wide-ranging minimum dimensionless stress intensity factors pertaining to diversified CCNBD geometries are recalibrated by three-dimensional finite element analysis, and an expression with tabulated coefficients is obtained through curve-fitting the data obtained from the numerical calibration. The present results are shown to be more accurate than those in the literature. Furthermore, the importance of the reasonability of the results is highlighted; a comprehensive comparison of different values shows that the upper bounds of minimum stress intensity factors are violated by the above claim. The confusion resulting from the claim is, thus, clarified conclusively.

Similar content being viewed by others

Abbreviations

- a :

-

Current crack length

- a 0 :

-

Initial chevron notched crack length

- a 1 :

-

Final chevron notched crack length

- a m :

-

Critical crack length

- b :

-

Width of crack front

- B :

-

Specimen thickness

- CCNBD:

-

Cracked chevron-notched Brazilian disc

- CSTBD:

-

Cracked straight-through Brazilian disc

- D :

-

Specimen diameter

- E :

-

Elastic modulus

- K I :

-

Stress intensity factor of the CCNBD

- K IC :

-

Mode I fracture toughness

- K II :

-

Mode II stress intensity factor

- K III :

-

Mode III stress intensity factor

- P :

-

Load applied on the specimen

- P max :

-

Maximum load

- R :

-

Specimen radius

- R s :

-

Saw radius

- SIF:

-

Stress intensity factor

- Y :

-

Dimensionless SIF of the CSTBD with dimensionless crack length α

- \( Y^{*} \) :

-

Dimensionless stress intensity factor of the CCNBD

- \( Y_{\min }^{*} \) :

-

Minimum (critical) dimensionless stress intensity factor

- α :

-

Dimensionless crack length

- α 0 :

-

Initial chevron notched dimensionless crack length

- α 1 :

-

Final chevron notched dimensionless crack length

- α m :

-

Critical dimensionless crack length

- α B :

-

Dimensionless thickness

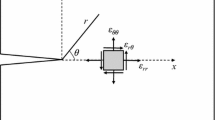

- γ :

-

Angle between the tension stress σ and the crack face

- μ :

-

Poisson’s ratio

- σ :

-

Tension stress

- ω :

-

Angle between the x-axis and the direction of projection of the stress on the crack face

References

Atkinson C, Smelser RE, Sanchez J (1982) Combined mode fracture via the cracked Brazilian disk test. Int J Fract 18(4):279–291

Chang S-H, Lee C-I, Jeon S (2002) Measurement of rock fracture toughness under modes I and II and mixed-mode conditions by using disc-type specimens. Eng Geol 66:79–97

Collins MP, Bentz EC, Sherwood EG, Xie L (2008) An adequate theory for the shear strength of reinforced concrete structures. Mag Concr Res 60(9):635–650

Dwivedi RD, Soni AK, Goel RK, Dube AK (2000) Fracture toughness of rocks under sub-zero temperature conditions. Int J Rock Mech Min Sci 37(8):1267–1275

Fowell RJ, Xu C (1993) The cracked chevron notched Brazilian disc test—geometrical considerations for practical rock fracture toughness measurement. Int J Rock Mech Min Sci Geomech Abstr 30:821–824

Fowell RJ, Xu C (1994) The use of the cracked Brazilian disc geometry for rock fracture investigations. Int J Rock Mech Min Sci Geomech Abstr 31(6):571–579

Gerstle WH, Ingraffea AR (1991) Compliance and stress-intensity factor calibration of the CENRBB specimen using the boundary element method. Int J Rock Mech Min Sci Geomech Abstr 28(1):85–92

Iqbal MJ, Mohanty B (2006) Experimental calibration of stress intensity factors of the ISRM suggested cracked chevron-notched Brazilian disc specimen used for determination of mode-I fracture toughness. Int J Rock Mech Min Sci 43:1270–1276

ISRM Testing Commission (1988, co-ordinator: F. Ouchterlony) Suggested methods for determining the fracture toughness of rock. Int J Rock Mech Min Sci Geomech Abstr 25:71–96

ISRM Testing Commission (1995, co-ordinator: R.J. Fowell) Suggested method for determining mode I fracture toughness using cracked chevron notched Brazilian disc (CCNBD) specimens. Int J Rock Mech Min Sci Geomech Abstr 32:57–64

ISRM Testing Commission (2007, editors: R. Ulusay, J.A. Hudson) The complete ISRM suggested methods for rock characterization, testing and monitoring: 1974–2006. ISRM

Libatskii LL, Kovchik SE (1967) Fracture of discs containing cracks. Mater Sci 3:334–339

Markides ChF, Pazis DN, Kourkoulis SK (2011) Stress intensity factors for the Brazilian disc with a short central crack: opening versus closing cracks. Appl Math Model 35:5636–5651

Matsuki K, Matsune S, Takahashi H (1991) Boundary element analysis for standard specimen configurations in the ISRM suggested methods for determining fracture toughness of rock. Int J Rock Mech Min Sci Geomech Abstr 28:355–363

Ouchterlony F (1990) Fracture toughness testing of rock with core based specimens. Eng Fract Mech 35:351–366

Shetty DK, Rosenfield AR, Duckworth WH (1985) Fracture toughness of ceramics measured by a chevron-notch diametral-compression test. J Am Ceram Soc 68(12):C-325–C-327

Tada H, Paris PC, Irwin GR (1985) The stress analysis of cracks handbook, 2nd edn. Paris Productions Inc., St. Louis

Wang QZ (1998) Stress intensity factors of the ISRM suggested CCNBD specimen used for mode-I fracture toughness determination. Int J Rock Mech Min Sci 35:977–982

Wang QZ (2010) Formula for calculating the critical stress intensity factor in rock fracture toughness tests using cracked chevron notched Brazilian disc (CCNBD) specimens. Int J Rock Mech Min Sci 47:1006–1011

Wang QZ, Jia XM, Kou SQ, Zhang ZX, Lindqvist P-A (2003) More accurate stress intensity factor derived by finite element analysis for the ISRM suggested rock fracture toughness specimen—CCNBD. Int J Rock Mech Min Sci 40:233–241

Wang QZ, Jia XM, Wu LZ (2004) Wide-range stress intensity factors for the ISRM suggested method using CCNBD specimens for rock fracture toughness tests. Int J Rock Mech Min Sci 41:709–716

Wang QZ, Gou XP, Fan H (2012) The minimum dimensionless stress intensity factor and its upper bound for CCNBD fracture toughness specimen analyzed with straight through crack assumption. Eng Fract Mech 82:1–8

Xu C, Fowell RJ (1994) Stress intensity factor evaluation for cracked chevron notched Brazilian disc specimens. Int J Rock Mech Min Sci Geomech Abstr 31:157–162

Yarema SY, Krestin GS (1966) Determination of the modulus of cohesion of brittle materials by compressive tests on disc specimens containing cracks. Mater Sci 2:7–10

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant No. 51179115), State Key Laboratory for GeoMechanics and Deep Underground Engineering (Grant No. K1020), and Doctoral Foundation of the Ministry of Education of China (Grant No. 200806100042).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Q.Z., Fan, H., Gou, X.P. et al. Recalibration and Clarification of the Formula Applied to the ISRM-Suggested CCNBD Specimens for Testing Rock Fracture Toughness. Rock Mech Rock Eng 46, 303–313 (2013). https://doi.org/10.1007/s00603-012-0258-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-012-0258-6