Abstract

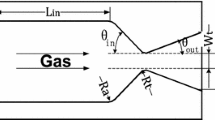

This paper proposes an orthogonal analysis method for decoupling the multiple nozzle geometrical parameters of microthrusters, thus an reconfigured design can be implemented to generate a proper thrust. In this method, the effects of various nozzle geometrical parameters, including throat width W t , half convergence angle θ in , half divergence angle θ out , exit-to-throat section ratio W e /W t and throat radius of the curvature R t /W t , on the performance of microthrusters are sorted by range analysis. Analysis results show that throat width seriously affects thrust because range value of 67.53 mN is extremely larger than the range value of other geometry parameters. For average specific impulse (ASI), the range value of exit-to-throat section ratio W e /W t and half divergence angle θ out are 4.82 s and 3.72 s, respectively. Half convergence angle with the range value of 0.39 s and throat radius with 0.32 s have less influence on ASI compared with exit-to-throat section ratio and half divergence angle. When increasing the half convergence angle from 10° to 40° and throat radius of the curvature from 3 to 9, average specific impulse initially decreases and then increases. A MEMS solid propellant thruster (MSPT) with the reconfigured geometrical parameters of nozzle is fabricated to verify the feasibility of the proposed method. The thrust of the microthruster can reach 25 mN. Power is estimated to be 0.84 W. This work provides design guideline to reasonably configure geometry parameters of microthruster.

Similar content being viewed by others

References

Ahn J, Lee D (2013) Computational prediction of the thrust characteristics of a small thruster at low pressure condition. In: Proceedings 49th AIAA/ASME/SAE/ASEE joint propulsion conference and exhibition, p 3908

Bayt R (1999) Analysis, fabricaiton and testing of a MEMS-based micro propulsion system. Massachusetts Institute of Technology, Cambridge

Cheah KH, Chin JK (2011) Performance improvement on MEMS micropropulsion system through a novel two-depth micronozzle design. Acta Astronaut 69:59–70

Cheah KH, Koh KS, Chiang CL et al (2011) Progress on development of Al2O3-Sio2 ceramic MEMS-based monopropellant micropropulsion system. In: Proceedings 47th AIAA/ASME/SAE/ASEE joint propulsion conference and exhibition, p 5923

Darbandi M, Roohi E (2013) Applying a hybrid Dsmc/Navier-stokes frame to explore the effect of splitter catalyst plates in micro/nanopropulsion systems. Sens Actuator A 189:409–419

Esper J, Neeck S, Slavin JA et al (2003) Nano/micro satellite constellations for earth and space science. Acta Astronaut 52:785–791

Gustafsson BK, Cuppoletti D, Gutmark E et al (2012) Nozzle throat optimization for supersonic jet noise reduction. In: Proceedings 50th AIAA aerospace sciences meeting including the new horizons forum and aerospace exposition, p 0247

Hitt DL, Zakrzwski CM, Thomas MA (2001) MEMS-based satellite micropropulsion via catalyzed hydrogen peroxide decomposition. Smart Mater Struct 10:1163–1175

Köhler J, Bejhed J, Kratz H et al (2002) A hybrid cold gas microthruster system for spacecraft. Sens Actuators A 97–98:587–598

Kondo K, Tanaka S, Habu H et al (2004) Vacuum test of a micro solid propellant rocket array thruster. IEICE Electronics Express. 1:222–227

Lee J, Kim T (2013) MEMS solid propellant thruster array with micro membrane igniter. Sens Actuators A 190:52–60

Lee J, Kim K, Kwon S (2010) Design, fabrication, and testing of MEMS solid propellant thruster array chip on glass wafer. Sens Actuators A 157:126–134

Lewis DH Jr, Janson SW, Cohen RB et al (2000) Digital micropropulsion. Sens Actuators A 80:143–154

London AP, Ayón AA, Epstein AH et al (2001) Microfabrication of a high pressure bipropellant rocket engine. Sens Actuators A 92:351–357

Louisos WF, Hitt DL (2008) Viscous effects on performance of two-dimensional supersonic linear micronozzles. J Propul Power 45:706–715

Louisos WF, Hitt DL (2011) Transient analysis of supersonic Viscous flow in 3D micronozzles. In: Proceedings 41st AIAA fluid dynamics conference and exhibition, p 3996

Mern J, Agarwal R (2013) A study of numerical simulation of supersonic conical nozzle exhaust. In: Proceedings 49th AIAA/ASME/SAE/ASEE joint propulsion conference and exhibition, p 3697

Rossi C, Larangot B, Lagrange D et al (2005) Final characterizations of mems based pyrotechnical microthrusters. Sens Actuators A 121:508–514

Sasanapuri B, Kumar M, Wirogo S et al (2013) Numerical simulation of a supersonic cruise nozzle. In: Proceedings 51th AIAA aerospace sciences meeting including the new horizons forum and aerospace exposition, p 0492

Shen Q, Yuan W, Li X et al (2013) A fully decoupled design method for mems microthruster based on orthogonal analysis. In: Proceedings transducers 2013, p 2353–2356

Spotts N, Guzik S, Gao X (2013) A CFD analysis of compressible flow through convergent-conical nozzles. In: Proceedings 49th AIAA/ASME/SAE/ASEE joint propulsion conference and exhibition, p 3734

Tanaka S, Kondo K, Habu H et al (2008) Test of B/Ti multilayer reactive igniters for a micro solid rocket array thruster. Sens Actuators A 144:361–366

Zelesnik D, Micci MM, Long LN (1993) DSMC simulation of low reynolds number nozzle flows. In: Proceedings 29th AIAA/SAE/ASME/ASEE joint propulsion conference and exhibition, p 2490

Zhang KL, Chou SK, Ang SS (2004) Development of a solid propellant microthruster with chamber and nozzle etched on a wafer surface. J Micromech Microeng 14:785–792

Zhao X, Xu W, Shi Y et al (2002) Mathematical statistics. Science Publishing House, Beijing

Acknowledgments

This research was sponsored by Chinese Hi-Tech Research and Development Program (Grant No. 2012AA0519, 2012AA0468) and Shaanxi Science and Technology Projects (Contract No. 2011KTCQ01-26).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shen, Q., Yuan, W., Li, X. et al. An orthogonal analysis method for decoupling the nozzle geometrical parameters of microthrusters. Microsyst Technol 21, 1157–1166 (2015). https://doi.org/10.1007/s00542-014-2240-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-014-2240-6