Abstract

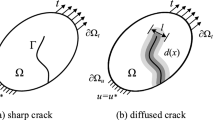

Localised deformation of materials usually takes place in thin bands during the nonlinear phase of the deformation process. The orientation and size of these localisation bands are important properties characterising the post-localisation behaviour of the materials, and hence should be taken into account in constitutive modelling. In this research, a new approach is proposed for the integration of both size and orientation of a localisation band in the constitutive description beyond the onset of localisation. Since a length scale related to the size of the localisation band appears in the model description, its post-localisation response then scales with both the band size and the size of the volume element containing it. Therefore, size effects are intrinsically included and post-localisation behaviour is correctly captured, which helps ensure convergence of numerical solutions upon discretisation refinement in numerical analysis of boundary value problems. The concept together with implementation features of the framework and its performances at constitutive level and in the analysis of boundary value problems are presented in this paper.

Similar content being viewed by others

References

Chemenda AI, Nguyen SH, Petit JP, Ambre J (2011) Mode I cracking versus dilatancy banding: Experimental constraints on the mechanisms of extension fracturing. J Geophys Res 116(B4):B11404

Desrues J, Viggiani G (2004) Strain localisation in sand: an overview of the experimental results obtained in Grenoble using stereophotogrammetry. Int J Numer Anall Methods Geomech 28(4):279–321

Drescher A, Vardoulakis I, Chunhua H (1990) A biaxial apparatus for testing soils. Geotech Test J 13:226–234

Du Bernard X, Eichhubl P, Aydin A (2002) Dilation bands: a new form of localised failure in granular media. Geophys Res Lett 29(24):29–31

Finno RJ, Harris WW, Mooney MA, Viggiani G (1997) Shear bands in plane strain compression of loose sand. Geotechnique 47(1):149–165

Lommatzsch M, Exner U, Gier S, Grasemann B (2015) Dilatant shear band formation and diagenesis in calcareous, arkosic sandstones, Vienna Basin (Austria). Mar Pet Geol 62:144–160

Vardoulakis I, Goldscheider M, Gudehus G (1978) Formation of shear bands in sand bodies as a bifurcation problem. Int J Numer Anal Methods Geomech 2(2):99–128

Vardoulakis I (1980) Shear band inclination and shear modulus of sand in biaxial tests. Int J Numer Anal Methods Geomech 4(2):103–119

Alshibli KA, Akbas IS (2007) Strain localisation in clay: plane strain versus triaxial loading conditions. Geotech Geol Eng 25(1):45–55

Bésuelle P, Viggiani G, Lenoir N, Desrues J, Bornert M (2010) X-ray micro CT for studying strain localisation in Clay Rocks under triaxial compression. In: Advances in X-ray tomography for geomaterials

Hicher PY, Wahyudi H, Tessier D (1994) Microstructural analysis of strain localisation in clay. Comput Geotech 16(3):205–222

Topolnicki M, Gudehus G, Mazurkiewicz BK (1990) Observed stress-strain behaviour of remoulded saturated clay under plane strain conditions. Géotechnique 40(2):155–187

Hutchinson JW, Tvergaard V (1981) Shear band formation in plane strain. Int J Solids Struct 17(5):451–470

Zhou M, Needleman A, Clifton RJ (1994) Finite element simulations of shear localisation in plate impact. J Mech Phys Solids 42(3):423–458

Baud P, Klein E, Wong TF (2004) Compaction localisation in porous sandstones: spatial evolution of damage and acoustic emission activity. J Struct Geol 26(4):603–624

Klein E, Baud P, Reuschlé T, Wong TF (2001) Mechanical behaviour and failure mode of Bentheim sandstone under triaxial compression. Phys Chem Earth Part A 26(1):21–25

Olsson WA (1999) Theoretical and experimental investigation of compaction bands in porous rock. J Geophys Res 104(B4):7219–7228

Wong TF, Baud P, Klein E (2001) Localised failure modes in a compactant porous rock. Geophys Res Lett 28(13):2521–2524

Cedolin L, Dei Poli S, Iori I (1983) Experimental determination of the fracture process zone in concrete. Cem Concr Res 13(4):557–567

Otsuka K, Date H (2000) Fracture process zone in concrete tension specimen. Eng Fract Mech 65(2):111–131

Alshibli KA, Sture S (1999) Sand shear band thickness measurements by digital imaging techniques. J Comput Civil Eng 13(2):103–109

Vardoulakis I, Sulem J (1995) Bifurcation analysis in geomechanics. Chapman & Hall, New York

Bažant ZP, Pijaudier-Cabot G (1989) Measurement of characteristic length of nonlocal continuum. J Eng Mech 115(4):755–767

Hill R (1958) A general theory of uniqueness and stability in elastic-plastic solids. J Mech Phys Solids 6(3):236–249

Neilsen MK, Schreyer HL (1993) Bifurcations in elastic-plastic materials. Int J Solids Struct 30(4):521–544

Ottosen NS, Runesson K (1991) Properties of discontinuous bifurcation solutions in elasto-plasticity. Int J Solids Struct 27(4):401–421

Rudnicki JW, Rice JR (1975) Conditions for the localisation of deformation in pressure-sensitive dilatant materials. J Mech Phys Solids 23(6):371–394

Runesson K, Ottosen NS, Dunja P (1991) Discontinuous bifurcations of elastic-plastic solutions at plane stress and plane strain. Int J Plast 7(1):99–121

Schreyer HL, Neilsen MK (1996) Discontinuous bifurcation states for associated smooth plasticity and damage with isotropic elasticity. Int J Solids Struct 33(20):3239–3256

Schreyer HL, Neilsen MK (1996) Analytical and numerical tests for loss of material stability. Int J Numer Methods Eng 39(10):1721–1736

Nguyen GD, Einav I, Korsunsky AM (2012) How to connect two scales of behaviour in constitutive modelling of geomaterials. Géotech Lett 2:129–134

Jirásek M, Bazant ZP (2002) Inelastic analysis of structures. Wiley, Hoboken

Borja RI (2008) Assumed enhanced strain and the extended finite element methods: a unification of concepts. Comput Methods Appl Mech Eng 197(33–40):2789–2803

Samaniego E, Belytschko T (2005) Continuum-discontinuum modelling of shear bands. Int J Numer Methods Eng 62(13):1857–1872

Sanborn SE, Prévost JH (2011) Frictional slip plane growth by localisation detection and the extended finite element method (XFEM). Int J Numer Anal Methods Geomech 35(11):1278–1298

Wells GN, Sluys LJ (2001) A new method for modelling cohesive cracks using finite elements. Int J Numer Methods Eng 50(12):2667–2682

Borja RI (2000) A finite element model for strain localisation analysis of strongly discontinuous fields based on standard galerkin approximation. Comput Methods Appl Mech Eng 190(11):1529–1549

Foster CD, Borja RI, Regueiro RA (2007) Embedded strong discontinuity finite elements for fractured geomaterials with variable friction. Int J Numer Methods Eng 72(5):549–581

Larsson R, Runesson K, Sture S (1996) Embedded localisation band in undrained soil based on regularized strong discontinuity theory and FE-analysis. Int J Solids Struct 33(20):3081–3101

Oliver J (1996) Modelling strong discontinuities in solid mechanics via strain softening constitutive equations. Part 2: numerical simulation. Int J Numer Methods Eng 39(21):3601–3623

Dias-da-Costa D, Alfaiate J, Sluys LJ, Júlio ENBS (2009) A discrete strong discontinuity approach. Eng Fract Mech 76(9):1176–1201

Mosler J (2004) On the modelling of highly localised deformations induced by material failure: the strong discontinuity approach. Arch Comput Methods Eng 11(4):389–446

Oliver J, Huespe AE, Pulido MDG, Chaves E (2002) From continuum mechanics to fracture mechanics: the strong discontinuity approach. Eng Fract Mech 69(2):113–136

Oliver J, Cervera M, Manzoli O (1999) Strong discontinuities and continuum plasticity models: the strong discontinuity approach. Int J Plast 15(3):319–351

Xu XP, Needleman A (1994) Numerical simulations of fast crack growth in brittle solids. J Mech Phys Solids 42:1397–1434

Belytschko T, Fish J, Engelmann BE (1988) A finite element with embedded localisation zones. Comput Methods Appl Mech Eng 70(1):59–89

Sluys LJ, Berends AH (1998) Discontinuous failure analysis for mode-I and mode-II localisation problems. Int J Solids Struct 35(31):4257–4274

Bažant ZP, Oh BH (1983) Crack band theory for fracture of concrete. Matériaux et Constr 16(3):155–177

De Borst R (2003) Numerical aspects of cohesive-zone models. Eng Fract Mech 70(14):1743–1757

De Borst R, Remmers JJ, Verhoosel CV (2014) Evolving discontinuities and cohesive fracture. Procedia IUTAM 10:125–137

Schreyer HL (1983) A third-invariant plasticity theory for frictional materials. J Struct Mech 11(2):177–196

Nguyen GD, Houlsby GT (2007) Non-local damage modelling of concrete: a procedure for the determination of model parameters. Int J Numer Anal Methods Geomech 31(7):867–891

Chan-O’Keeffe S, Tang S, Kopacz AM, Smith J, Rowenhorst DJ, Spanos G, Liu WK, Olson GB (2015) Multiscale ductile fracture integrating tomographic characterization and 3-D simulation. Acta Mater 82:503–510

Tang S, Kopacz AM, Chan-O’Keeffe S, Olson GB, Liu WK (2013) Concurrent multiresolution finite element: formulation and algorithmic aspects. Comput Mech 52(6):1265–1279

Tang S, Kopacz AM, Chan-O’Keeffe S, Olson GB, Liu WK (2013) Three-dimensional ductile fracture analysis with a hybrid multiresolution approach and microtomography. J Mech Phys Solids 61(11):2108–2124

Liu WK, Qian D, Gonella S, Li S, Chen W, Chirputkar S (2010) Multiscale methods for mechanical science of complex materials: bridging from quantum to stochastic multiresolution continuum. Int J Numerl Methods Eng 83(8–9):1039–1080

Tian R, Chan S, Tang S, Kopacz AM, Wang J-S, Jou H-J, Siad L, Lindgren L-E, Olson GB, Liu WK (2010) A multiresolution continuum simulation of the ductile fracture process. J Mech Phys Solids 58(10):1681–1700

Bažant ZP (1976) Instability, ductility, and size effect in strain-softening concrete. J Eng Mech Div 102(2):331–344

Schreyer HL, Sulsky DL, Munday LB, Coon MD, Kwok R (2006) Elastic-decohesive constitutive model for sea ice. J Geophys Res 111(C11)

Gajo A, Bigoni D, Wood DM (2004) Multiple shear band development and related instabilities in granular materials. J Mech Phys Solids 52(12):2683–2724

Pietruszczak S, Mroz Z (2001) On failure criteria for anisotropic cohesive-frictional materials. Int J Numer Anal Methods Geomech 25(5):509–524

Pietruszczak S, Xu G (1995) Brittle response of concrete as a localisation problem. Int J Solids Struct 32:1517–1533

Xu G, Pietruszczak S (1997) Numerical analysis of concrete fracture based on a homogenisation technique. Comput Struct 63:497–509

Nguyen GD, Korsunsky AM, Einav I (2014) A constitutive modelling framework featuring two scales of behaviour: fundamentals and applications to quasi-brittle failure. Eng Fract Mech 115:221–240

Nguyen GD (2011) A damage model with evolving nonlocal interactions. Int J Solids Struct 48(10):1544–1559

Hill R (1963) Elastic properties of reinforced solids: some theoretical principles. J Mech Phys Solids 11(5):357–372

Nguyen GD (2014) An Enriched constitutive model for fracture propagation analysis using the material point method. Appl Mech Mater 553:731–736

Chambon R, Crochepeyre S, Desrues J (2000) Localisation criteria for non-linear constitutive equations of geomaterials. Mech Cohesive-frictional Mater 5(1):61–82

Das A, Nguyen GD, Einav I (2011) Compaction bands due to grain crushing in porous rocks: a theoretical approach based on breakage mechanics. J Geophys Res 116(B8):1–14

Ortiz M, Leroy Y, Needleman A (1987) A finite element method for localised failure analysis. Comput Methods Appl Mech Eng 61(2):189–214

Nguyen CT, Nguyen GD, Das A, Bui HH (2016) Constitutive modelling of progressive localised failure in porous sandstones under shearing at high confining pressures. J Mech Phys Solids, under revision

Borja RI (1991) Cam-Clay plasticity, part II: implicit integration of constitutive equation based on a nonlinear elastic stress predictor. Comput Methods Appl Mech Eng 88(2):225–240

Simo JC, Hughes TJ (2006) Computational inelasticity. Springer Science & Business Media, Berlin

Drucker DC, Prager W (1952) Soil mechanics and plasticity analysis of limit design. Quart Appl Math 10:157–165

Mises RV (1913) Mechanik der festenKörperim plastisch-deformablenZustand. Nachrichtenvon der Gesellschaft der Wissenschaften zu Göttingen. Math Phys Klasse 70:582–592

Sluys LJ (1992) Wave propagation, localisation and dispersion in softening solids. Delft University of Technology, Delft

Sulsky D, Chen Z, Schreyer HL (1994) A particle method for history-dependent materials. Comput Methods Appl Mech Eng 118(1–2):179–196

Naylor DJ (1974) Stresses in nearly incompressible materials by finite elements with application to the calculation of excess pore pressures. Int J Numer Methods Eng 8(3):443–460

Smith IM, Griffiths DV, Margetts L (2013) Programming the finite element method. Wiley, New York

Bolton MD, Gui MW, Garnier J, Corte JF, Bagge G, Laue J, Renzi R (1999) Centrifuge cone penetration tests in sand. Géotechnique 49:543–552

McDowell GR, Bolton MD (2000) Effect of particle size distribution on pile tip resistance in calcareous sand in the geotechnical centrifuge. Granul Matter 2(4):179–187

Skempton AW (1986) Standard penetration test procedures and the effects in sands of overburden pressure, relative density, particle size, ageing and overconsolidation. Geotechnique 36(3):425–447

Petersson PE (1981) Crack growth and development of fracture zones in plain concrete and similar materials. In Report TVBM-1006, Div. of Build. Mat., Lund Institute of Technology, Lund

Grassl P, Jirásek M (2010) Meso-scale approach to modelling the fracture process zone of concrete subjected to uniaxial tension. Int J Solids Struct 47(7–8):957–968

Ren W, Yang Z, Sharma R, Zhang C, Withers PJ (2015) Two-dimensional X-ray CT image based meso-scale fracture modelling of concrete. Eng Fract Mech 133:24–39

Kolymbas D, Rombach G (1989) Shear band formation in generalized hypoelasticity. Ing Archiv 59:177–186

De Borst R, Sluys LJ, Muhlhaus HB, Pamin J (1993) Fundamental issues in finite element analyses of localisation of deformation. Eng Comput 10(2):99–121

Ladeveze P (1983) Sur une theorie de l’endommagement anisotrope. LMT Cachan, Cachan

Acknowledgments

Funding support from the Australian Research Council via projects DP140100945 (Luming Shen, Giang D. Nguyen), FT140100408 (Giang D. Nguyen) and LP130100884 and DP160100775 (Ha H. Bui) is gratefully acknowledged. The authors would like to express the gratitude towards Drs. Erik Jan Lingen and Martijn Stroeven at the Dynaflow Research Group, The Netherlands, for providing us with the numerical toolkit jem/jive.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1

In this section, the Von Mises and Drucker–Prager constitutive models are briefly summarised, details of those two models can be found elsewhere in literature [19, 74, 76, 87].

1.1 Yield criterion

The Von Mises criterion is a pressure-independent criterion which is normally used for metals and normally-consolidated clays under relatively rapid loading conditions (undrained behaviour). The yield function following the Von Mises criterion is:

in which c is the yield strength which is a function of the softening parameter \(\kappa \), and

is the second invariant of the deviatoric stresses \({\varvec{s}}={\varvec{\sigma }}-p{{\varvec{\delta }} }\) with \(p=\frac{1}{3}\left( \sigma _{1}+\sigma _{2}+\sigma _{3} \right) \) being the hydrostatic pressure, and \({{\varvec{\delta }} }\) the Kronecker delta. The softening parameter \(\kappa \) is normally dependent on the strain history and in this paper the rate of \(\kappa \) is defined as the second invariant of the plastic strain vector \(\dot{{{\varvec{e}}}}^{p}\) based on the strain hardening hypothesis:

and then \(\kappa \) can be integrated along the loading path as:

The softening rule for the yield strength c is either linear- or exponential-function of \(\kappa \) as following:

or:

with \(c_{0}\) being the initial yield strength, b the softening modulus and a a parameter governing the residual strength of the material.

The Drucker–Prager criterion includes a dependence on the hydrostatic pressure p which is widely used to describe the inelastic behaviour of granular materials, drained clays, rock and concrete under compression. The Drucker–Prager yield function is defined as:

with \(\alpha ,\beta \) constants given by:

in which \(\varphi \) is the internal friction angle and c is the cohesion of a material which is a function of the softening parameter \(\kappa \) (Eq. 40). The concept of non-associative flow is applied by defining the plastic potential \(g\left( {\varvec{\sigma }},\kappa \right) \) equal to \(f\left( {\varvec{\sigma }},\kappa \right) \) but with the dilatancy angle \(\psi \) substituted for the friction angle \(\varphi \).

1.2 Flow rule

The Von Mises and Drucker–Prager constitutive models are classical elasto-plastic models in which the evolution of the plastic strains can be written as:

with \(\dot{\lambda }\) being the non-negative plastic multiplier determining the magnitude of the plastic flow and \({\varvec{l}}\) the plastic flow direction. In case of non-associative plasticity, \({\varvec{l}}\) is replaced by \({\varvec{m}}=\frac{\partial g}{\partial {\varvec{\sigma }}}\).

1.3 Tangent stiffness

The tangent stiffness of elasto-plastic constitutive models can be derived in the same procedure. Firstly, the relation between the stress and the elastic strain is defined:

in which \({\varvec{D}}^{e}\) is the elastic stiffness. Secondly, the consistency condition of the plastic flow can be written as:

From the definitions (38) and (44), the hardening variable can be defined as a function of the plastic multiplier:

with \({\varvec{h}}\) being a vector function of the stress and the hardening variable. If we define the hardening modulus h as:

then the consistency condition can be rewritten as:

Differentiating Eq. (45) and substituting it in the consistency condition yield an expression for the magnitude of the plastic flow:

Finally, back substitution the expression of \(\dot{\lambda }\) to the rate form of Eq. (45) leads to the relationship between the stress rate \(\dot{{\varvec{\sigma }} }\) and the strain rate \(\dot{{\varvec{\varepsilon }} }\) in the form:

with \({\varvec{D}}\) being the tangent stiffness.

Appendix 2

Assuming a linear softening behaviour for the material inside the localization band (Fig. 24), with tangent stiffness \(a_{o}>0\) and \(a_{i}<0\) in one-dimensional (1D) cases for the behaviour outside and inside the localization band, respectively. The 1D formulation (Eq. 16) in this case involves inverting \({\left( 1-f \right) a}_{i}+{fa}_{o}\) that can be singular. We will investigate when this singularity can happens in this specific case.

Given the material fracture energy \(G_{F}\) as the energy released due to cracking and the width h of the localiaation band (termed Fracture Process Zone in concrete/rock cracking), we have the following relationship (see Fig. 24):

From this equation, we obtain

On the other hand, from the singularity of \({\left( 1-f \right) a}_{i}+{fa}_{o}\) we can write:

Equating (53) and (54) we can find the condition that makes \({\left( 1-f \right) a}_{i}+{fa}_{o}\) singular:

After a few manipulations, the above condition becomes:

This is in fact the value of fracture energy \(G_{F}\) below which there is macro snap back. The above condition (56) therefore corresponds to perfectly brittle behaviour in the macro response, and singularity in this simple 1D case just happens when \(G_{F}\) is equal to that limit. Higher or lower values of \(G_{F}\) will therefore not affect the inversion of \({\left( 1-f \right) a}_{i}+{fa}_{o}\), and in all these cases it can be straightforwardly proved that the displacement velocity is always a monotonically increasing quantity.

Appendix 3

For quasi-brittle behaviour, a damage model characterising the effects of micro-cracking on the material response can be used. In such cases, the behaviour of the material inside the localisation band is governed by the following constitutive equations:

where \({\varvec{\sigma }}_{i}^{\mathrm {+}}\) is the “positive” part of the stress inside the localisation band, obtained using the eigenvalue decomposition [88]. The evolution of the scalar damage variable \(\mathrm {D}\) is governed by function \(F\left( D \right) \) of the form:

in which \(f_{t}^{{\prime }}\) is the uniaxial tensile strength, and two parameters \(E_{p}\) and n are determined from the fracture energy of the material. Details on links between these parameters and the fracture energy can be found in [52]. The nonlocal version of the model can be found in [65].

Rights and permissions

About this article

Cite this article

Nguyen, G.D., Nguyen, C.T., Nguyen, V.P. et al. A size-dependent constitutive modelling framework for localised failure analysis. Comput Mech 58, 257–280 (2016). https://doi.org/10.1007/s00466-016-1293-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00466-016-1293-z