Abstract

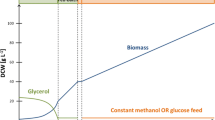

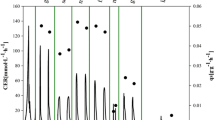

Recently, Pichia pastoris has been the focal point of interest as an expression system for production of many recombinant proteins. The study and optimization of feeding strategy are of major importance to achieve maximum volumetric productivity in fed-batch cultivations. Among different feeding strategies used in P. pastoris fed-batch cultures, those trying to maintain a constant specific growth rate have usually resulted in superior productivities. The objective of the present study was to investigate and optimize the co-feeding of glycerol and methanol to attain maximum expression of t-PA in P. pastoris fed-batch cultures with constant specific growth rate. The experiments were designed by response surface methodology, considering the specific feeding rates of methanol and glycerol as independent variables. In each experiment, glycerol and methanol were fed according to a predetermined equation to maintain a constant specific growth rate. It was found that with glycerol feeding for higher specific growth rates, the inhibitory properties of glycerol are more pronounced, while the best expression level was achieved when the ratio of µ set glycerol to that of methanol was around 1.67. In all specific growth rates tested, almost a similar ratio of the specific glycerol feeding rate to that of methanol led to the maximum protein production and activity. The statistical model predicted the optimal operating conditions for µ set glycerol and that of methanol to be 0.05 and 0.03 h−1, respectively. Applying the optimum strategy, maximum of 52 g/L biomass, 300 mg/L t-PA and 340,000 IU/mL enzyme activity were obtained.

Similar content being viewed by others

References

Inan M, Chiruvolu V, Eskridge KM, Vlasuk GP, Dickerson K, Brown S, Meagher MM (1999) Optimization of temperature-glycerol-pH conditions for a fedbatch fermentation process for recombinant hookworm (Ancylostoma caninum) anticoagulant peptide (AcAP-5) production by Pichia pastoris. Enzyme Microb Technol 24:438–445

Jafari R, Sundstrom BE, Holm P (2011) Optimization of production of the anti-keratin 8 single-chain Fv TS1-218 in Pichia pastoris using design of experiments. Microb Cell Fact 10:34

Ghosalkara A, Sahaia V, Srivastava A (2008) Optimization of chemically defined medium for recombinant Pichia pastoris for biomass production. Bioresour Technol 99:7906–7910

Gurramkonda C, Polez S, Skoko N, Adnan A, Gäbel T, Chugh D, Swaminathan S, Khanna N, Tisminetzky S, Rinas U (2010) Application of simple fed-batch technique to high-level secretory production of insulin precursor using Pichia pastoris with subsequent purification and conversion to human insulin. Microb Cell Fact 9:31

Heyland J, Fu J, Blank LM, Schmid A (2011) Carbon metabolism limits recombinant protein production in Pichia pastoris. Biotechnol Bioeng 108:1942–1953

Chung BKS, Selvarasu S, Camattari A, Ryu J, Lee H, Ahn J, Lee H, Lee DY (2010) Genome-scale metabolic reconstruction and in silico analysis of methylotrophic yeast Pichia pastoris for strain improvement. Microb Cell Fact 9:50

Jordà J, Jouhten P, Cámara E, Maaheimo H, Albiol J, Ferrer P (2012) Metabolic flux profiling of recombinant protein secreting Pichia pastoris growing on glucose:methanol mixtures. Microb Cell Fact 11:57

Heyland J, Fu J, Blank LM, Schmid A (2010) Quantitative physiology of Pichia pastoris during glucose-limited high-cell density fed-batch cultivation for recombinant protein production. Biotechnol Bioeng 107:357–368

Ren H, Yuan J (2005) Model-based specific growth rate control for Pichia pastoris to improve recombinant protein production. J Chem Technol Biol 80:1268–1272

Schenk J, Balazs K, Jungo C, Urfer J, Wegmann C, Zocchi A, Marison IW, von Stockar U (2008) Influence of specific growth rate on specific productivity and glycosylation of a recombinant avidin produced by a Pichia pastoris Mut+ strain. Biotechnol Bioeng 99:368–377

Pichia Fermentation Process Guidelines, Invitrogen Life Technologies http://tools.lifetechnologies.com/content/sfs/manuals/pichiaferm_prot.pdf. Accessed 28 July 2015

Files D, Ogawa M, Scaman CH, Baldwin SA (2001) A Pichia pastoris fermentation process for producing high-levels of recombinant human cystatin-C. Enzyme Microb Technol 29:335–340

d’Anjou M, Daugulis A (2000) Mixed-feed exponential feeding for fed-batch culture of recombinant methylotrophic yeast. Biotechnol Lett 22:341–346

Maghsoudi A, Hosseini S, Shojaosadati SA, Vasheghani-Farahani E, Nosrati M, Bahrami A (2012) A new methanol-feeding strategy for the improved production of β-galactosidase in high cell-density fed-batch cultures of Pichia pastoris Mut+ strains. Biotechnol Bioprocess Eng 17:76–83

Azimzadeh Irani Z, Maghsoudi A, Shojaosadati SA, Motamedian E (2015) Development and in silico analysis of a new nitrogen-limited feeding strategy for fed-batch cultures of Pichia pastoris based on a simple pH-control system. Biochem Eng J 98:1–9

Zhang W, Hywood Potter KJ, Plantz BA, Schlegel VL, Smith LA, Meagher MM (2003) Pichia pastoris fermentation with mixed-feeds of glycerol and methanol: growth kinetics and production improvement. J Ind Microbiol Biotechnol 30:210–215

Julien C (2006) Production of humanlike recombinant proteins in Pichia pastoris. BioProcess Int 4:22–31

Gao M, Shi Z (2013) Process control and optimization for heterologous protein production by methylotrophic Pichia pastoris. Chin J Chem Eng 21:216–226

Cereghino GP, Cereghino JL, Ilgen C, Cregg JM (2002) Production of recombinant proteins in fermenter cultures of the yeast Pichia pastoris. Curr Opin Biotechnol 13:329–332

Vanz AL, Lünsdorf H, Adnan A, Nimtz M, Gurramkonda C, Khanna N, Rinas U (2012) Physiological response of Pichia pastoris GS115 to methanol-induced high level production of the Hepatitis B surface antigen: catabolic adaptation, stress responses, and autophagic processes. Microb Cell Fact 11:103

Poutou-Pinales RA, Cordoba-Ruiz HA, Barrera-Avellaneda LA, Delgado-Boada JM (2010) Carbon source feeding strategies for recombinant protein expression in Pichia pastoris and Pichia methanolica. Afr J Biotechnol 9:2173–2184

Jungo C, Marison I, von Stockar U (2007) Mixed feeds of glycerol and methanol can improve the performance of Pichia pastoris cultures: a quantitative study based on concentration gradients in transient continuous cultures. J Biotechnol 128:824–837

Kazemali M, Majidzadeh-A K, Sardari S, Saadatirad AH, Khalaj V, Zarei N, Barkhordari F, Adeli A, Mahboudi F (2014) Design of a novel chimeric tissue plasminogen activator with favorable Vampire bat plasminogen activator properties. Enzyme Microb Tech 67:82–86

Tolner B, Smith L, Begent RH, Chester KA (2006) Production of recombinant protein in Pichia pastoris by fermentation. Nat Protoc 1:1006–1021

Shuler ML, Kargi F (2002) Bioprocess engineering basic concepts. Prentice Hall, Houston

Tsuzuki S, Murai N, Miyake Y, Inouye K, Hirayasu H, Iwanaga T, Fushiki T (2005) Evidence for the occurrence of membrane-type serine protease 1/matriptase on the basolateral sides of enterocytes. Biochem J 388:679–687

Zhang W, Inan M, Meagher MM (2000) Fermentation strategies for recombinant protein expression in the methylotrophic yeast Pichia pastoris. Biotechnol Bioprocess Eng 5:275–287

Jungo C, Schenk J, Pasquier M, Marison IW, von Stockar U (2007) A quantitative analysis of the benefits of mixed feeds of sorbitol and methanol for the production of recombinant avidin with Pichia pastoris. J Biotechnol 131:57–66

Cregg JM, Cereghino JL, Shi J, Higgins DR (2000) Recombinant protein expression in Pichia pastoris. Mol Biotechnol 16:23–52

Werner RG, Goetz F, Tayapiwatana C, Manosroi J, Manosroi A (2002) Methods for large scale protein production in prokaryotes. Patent WO2002040696 A3

Gulba DC, Bode C, Runge MS, Huber K (1998) Thrombolytic agents: an updated overview. Fibrinolysis Proteol 12:39–58

Bretthauer RK (2003) Genetic engineering of Pichia pastoris to humanize N-glycosylation of proteins. Trends Biotechnol 21:459–462

Zhang N, Liu L, Dumitru CD, Cummings NR, Cukan M, Jiang Y, Li Y, Li F, Mitchell T, Mallem MR, Ou Y, Patel RN, Vo K, Wang H, Burnina I, Choi BK, Huber HE, Stadheim TA, Zha D (2011) Glycoengineered Pichia produced anti-HER2 is comparable to trastuzumab in preclinical study. MAbs 3:289–298

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kazemali, M.R., Majidzadeh, K., Sardari, S. et al. Enhanced truncated-t-PA (CT-b) expression in high-cell-density fed-batch cultures of Pichia pastoris through optimization of a mixed feeding strategy by response surface methodology. Bioprocess Biosyst Eng 39, 565–573 (2016). https://doi.org/10.1007/s00449-016-1538-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-016-1538-4