Abstract

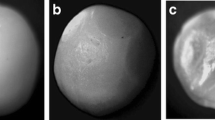

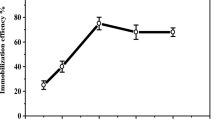

The hybrid alginate/gelatin/calcium oxalate (AGOCa) support was successfully synthesized through the biomimetic mineralization method for immobilization in situ of a pectinolytic extract from Aspergillus niger ATCC 9642 via entrapment technique. The efficiency of immobilization reached 72.7 %. Sodium oxalate buffer (100 mM, pH 5.5) was selected as adjuvant of the immobilization process by allowing the formation of a calcified shell around the calcium alginate capsule, significantly increasing the stability to storage, thermal and recycling of the enzymatic immobilized pectinolytic extract. The pH and temperature for maximum activity were from 5.0 to 6.0 and 60 to 80 °C, respectively. The new hybrid support can be a potential alternative to obtain immobilized pectinases with properties for advantageous industrial applications.

Similar content being viewed by others

References

Pinelo M, Zeuner B, Meyer AS (2010) Juice clarification by protease and pectinase treatments indicates new roles of pectin and protein in cherry juice turbidity. Food Bioprod Process 88:259–265

Sandri IG, Fontana RC, Barfknecht DM, Da Silveira MM (2011) Clarification of fruit juices by fungal pectinases. Lwt Food Sci Technol 44:2217–2222

Uenojo M, Pastore GM (2007) Pectinolytic enzymes. Industrial applications and future perspectives. Quím Nova 30:388–394

Seenuvasan M, Malar CG, Preethi S, Balaji N, Iyyappan J, Kumar MA, Kumar KS (2013) Immobilization of pectinase on co-precipitated magnetic nanoparticles for enhanced stability and activity. Res J Biotechnol 8:24–30

Abdelmajeed N, Kheli O, Danial E (2012) Immobilization technology for enhancing bio-products industry. Afr J Biotechnol 11:13528–13539

Tischer W, Wedekind F (1999) Immobilized enzymes: methods and applications. Top Curr Chem 200:95–126

Datta S, Christena L, Rajaram YR (2013) Enzyme immobilization: an overview on techniques and support materials. 3 Biotech 3:1–9

Talbert JN, Goddart JM (2012) Enzymes on material surfaces. Colloid Surf B 93:8–19

Lu Z, Zhang J, Ma Y, Song S, Gu W (2012) Biomimetic mineralization of calcium carbonate/carboxymethylcellulose. Mater Sci Eng 32:1982–1987

Gao Q, Wang C, Tong Z (2010) Facile and high efficient fabrication of hybrid microcapsules for urease encapsulation and their use as biomimetic reactors. Res Chin Univ 26(5):842–846

Lai JK, Chuang TH, Jan JS, Wang SS (2010) Efficient and stable enzyme immobilization in a block copolypeptide vesicle-templated biomimetic silica support. Colloids Surf B 80:51–58

Zhang L, Jiang Y, Jiang Z, Sun X, Shi J, Cheng W, Sun Q (2009) Immobilized transglucosidase in biomimetic polymer-inorganic hybrid capsules for efficient conversion of maltose to isomaltooligosaccharides. Biochem Eng J 46:186–192

Lee JH, Kim SB, Park C, Kim SW (2010) Effect of a buffer mixture system on the activity of lipases during immobilization process. Biores Technol 101:S66–S70

Gomes J, Zeni J, Cence K, Toniazzo G, Treichel H, Valduga E (2011) Evaluation of production and characterization of polygalacturonase by Aspergillus niger ATCC 9642. Food Bioprod Process 89:281–287

Boanini E, Bigi A (2011) Biomimetic gelatin–octacalcium phosphate core–shell microspheres. J Colloid Interface Sci 362:594–599

Shen Q, Yanga R, Hua X, Ye F, Zhang W, Zhao W (2011) Gelatin-templated biomimetic calcification for β-galactosidase immobilization. Process Biochem 46:1565–1571

Miller GL (1959) Use of dinitrosalicyclic acid reagent for determination of reducing sugar. Anal Chem 37:426–428

Al-Wahsh IA, Wu Y, Liebman M (2012) A comparison of two extraction methods for food oxalate assessment. J Food Res 1:233–239

Hoffman AS (2012) Hydrogels for biomedical applications. Adv Drug Deliv Rev 64:18–23

Pasparakis G, Bouropoulos N (2006) Swelling studies and in vitro release of verapamil from calcium alginate and calcium alginate–chitosan beads. Int J Pharm 323:34–42

Ouwerx C, Velings N, Mestdagh M, Axelos M (1998) Physicochemical properties and rheology of alginate gel beads formed with various divalent cations. Polym Gels Netw 6:393–408

Fundueanu G, Nastruzzi C, Carpov A, Desbrieres J, Rinaudo M (1999) Physico-chemical characterization of Ca-alginate microparticles produced with different methods. Biomaterials 20:1427–1435

Yoo SH, Song YB, Chang PS, Lee HG (2006) Microencapsulation of α-tocopherol using sodium alginate and its controlled release properties. Int J Biol Macromol 38:25–30

Zhang L, Jiang Y, Shi J, Sun X, Li J, Jiang Z (2008) Biomimetic polymer-inorganic hybrid microcapsules for yeast alcohol dehydrogenase encapsulation. React Funct Polym 68:1507–1515

Reham HU, Aman A, Silipo A, Qader SA, Molinaro A, Ansari A (2013) Degradation of complex carbohydrate: immobilization of pectinase from Bacillus licheniformis KIBGE-IB21 using calcium alginate as a support. Food Chem 139:1081–1086

Shukla S, Saxena S, Thakur J, Gupta R (2010) Immobilization of polygalacturonase from Aspergillus niger onto glutaraldehyde activated nylon-6 and its application in apple juice clarification. Acta Aliment Hung 39:277–299

Li T, Li S, Wa N, Tain L (2008) Immobilization and stabilization of pectinase by multipoint attachment onto an activated agar-gel support. Food Chem 109:703–708

Ramirez H, Briones A, Úbeda J, Arevalo M (2013) Immobilization of pectinase by adsorption on an alginate-coated chitin support. Biotechnol Appl 30:101–104

Pifferi P, Spagna G (1987) The immobilization of endopolygalacturonase on γ-alumina. J Mol Catal B Enzym 42:137–149

Esawy MA, Gamal AA, Kamel Z, Ismail AS, Abdel-Fattah AF (2013) Evaluation of free and immobilized Aspergillus niger NRC1ami pectinase applicable in industrial processes. Carbohyd Polym 92:1463–1469

Bahrami A, Hejazi P (2013) Electrostatic immobilization of pectinase on negatively charged AOT-Fe3O4 nanoparticles. J Mol Catal B Enzym 93:1–7

Csanádi Z, Sisak C (2006) Immobilization of pectinex Ultra SP-L pectinase and its application to production of fructooligosaccharides. Acta Aliment Hung 35:205–212

Wang B, Cheng F, Lu Y, Ge W, Zhang M, Yue B (2013) Immobilization of pectinase from Penicillium oxalicum F67 onto magnetic corn starch microspheres: characterization and application in juice production. J Mol Catal B Enzym 97:137–143

Simões AS, Mori RY, Faria R, De Castro HF, Mendes AA (2011) Performance of hybrid matrix SiO2-chitosan to immobilize microbial lipase from Candida rugosa. Quim Nova 34:33–38

Lei Z, Bi S (2007) The silica-coated chitosan particle from a layer-by-layer approach for pectinase immobilization. Enzym Microb Technol 40:1442–1447

Li T, Wang N, Li S, Zhao Q, Guo M, Zhang C (2007) Optimization of covalent immobilization of pectinase on sodium alginate support. Biotechnol Lett 29:1413–1416

Buga M, Ibrahim S, Nok A (2010) Physico-chemical characteristics of immobilized polygalacturonase from Aspergillus niger (AS6). Afr J Biotechnol 9:8934–8943

Spagna G, Pifferi P, Tramontini M (1995) Immobilization and stabilization of pectinlyase on sinthetic polymers for application in the beverage industry. J Mol Catal B Enzym 101:99–105

Wu R, He B, Zhao G, Li X (2014) Immobilization of pectinase on polyethyleneimine-coated pulp fiber for treatment of whitewater from papermaking. J Mol Catal B Enzym 99:163–168

Won K, Sangbum K, Kwang-Je K, Hong P, Sang-Ji M (2005) Optimization of lipase entrapment in Ca-alginate gel bead. Process Biochem 40:2149–2154

Acknowledgments

The authors thank URI-Erechim, CNPq, FAPERGS and CAPES for the infrastructure and financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bustamante-Vargas, C.E., Mignoni, M.L., de Oliveira, D. et al. Synthesis of a hybrid polymer-inorganic biomimetic support incorporating in situ pectinase from Aspergillus niger ATCC 9642. Bioprocess Biosyst Eng 38, 1569–1577 (2015). https://doi.org/10.1007/s00449-015-1399-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-015-1399-2