Abstract

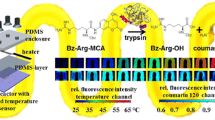

A concept for the determination of concentrations in microchannels using FT-IR spectroscopy in transmission is presented. The fundamental idea of spatially resolved measurements along several measuring points was implemented in a single-channel microreactor. Compared to existing microreactor setups for the analysis of fast chemical reactions or mixing processes, the presented concept enables longer residence times at appropriate resolution. Once steady-state conditions were reached in the reactor, mid-infrared spectra were collected at different locations. Information throughout the considered conversion range is available, which is of great importance to analyze inhibitory effects, next to the kinetic constants (v max and K M). Therefore, this technology enables a rapid screening of (bio-)catalysts, substrate specificity and process conditions. In particular, the analysis of real substrates instead of model substrates and the possibility to follow side reactions and follow-up reactions during enzymatic catalysis open a broad field of application.

Similar content being viewed by others

Abbreviations

- 2D:

-

Two-dimensional

- ASE:

-

Advanced silicon etching

- ATR:

-

Attenuated total reflectance

- CalB:

-

Candida antarctica lipase B

- FID:

-

Flame ionization detector

- FT-IR:

-

Fourier transform infrared

- GC:

-

Gas chromatography

- IR:

-

Infrared

- LaOEt:

-

Ethyl levulinate

- LOD:

-

Limit of detection

- LOQ:

-

Limit of quantitation

- µTAS:

-

Micro total analysis system

- PLS:

-

Partial least squares

- RMSECV:

-

Root mean square error of cross-validation

- SERS:

-

Surface-enhanced Raman spectroscopy

- STR:

-

Stirred tank reactor

- b, b 0 :

-

Regression coefficient

- c La :

-

Concentration of levulinic acid

- c LaOEt :

-

Concentration of ethyl levulinate

- E(θ):

-

Density curve of dimensionless residence time

- v max :

-

Maximum reaction rate

- K I :

-

Inhibition constant

- K M :

-

Michaelis constant

- n :

-

Number of data sets

- θ :

-

Dimensionless residence time

- v :

-

Reaction rate

- x i :

-

Measured spectrum

- y i :

-

Calibration value

- \({\hat{y}}_{i}\) :

-

Predicted value

References

Urban PL, Goodall DM, Bruce NC (2006) Enzymatic microreactors in chemical analysis and kinetic studies. Biotech Adv 24(1):42–57

Hartmann RL, Jensen KF (2009) Microchemical systems for continuous-flow synthesis. Lab Chip 9(17):2495–2507

Jahnisch K, Hessel V, Lowe H, Baerns M (2004) Chemistry in microstructured reactors. Angew Chem Int Ed 43:406–446

Fagaschewski J, Bohne S, Kaufhold D, Müller J, Hilterhaus L (2012) Modular micro reaction engineering for carboligation catalyzed by benzoylformate decarboxylase. Green Process Synth 1(4):337–344

Minnich CB, Sipeer F, Greiner L, Liauw MA (2010) Determination of the dispersion characteristics of miniaturized coiled reactors with fiber-optic Fourier transform mid-infrared spectroscopy. Ind Eng Chem Res 49:5530–5535

Bodla VK, Seerup R, Krühne U, Woodley JM, Gernaey KV (2013) Microreactors and CFD as tools for biocatalysis reactor design: a case study. Chem Eng Techn 36(6):1017–1026

Kara S, Anton F, Solle D, Neumann M, Hitzmann B, Scheper T, Liese A (2010) Fluorescence spectroscopy as a novel method for on-line analysis of biocatalytic C–C bond formations. Mol Cat B 66(1–2):124–129

Hill EK, de Mello AJ (2010) Single-molecule detection using confocal fluorescence detection: assessment of optical probe volumes. Analyst 125:1033–1036

Ferstl W, Klahn T, Schweikert W, Billeb G, Schwarzer M, Loebbecke S (2007) Inline analysis in microreaction technology: a suitable tool for process screening and optimization. Chem Eng Technol 30(3):370–378

Xiao Y, Yu XD, Wang K, Xu JJ, Huang J, Chen HY (2007) Study on the separation of amino acids in modified poly(dimethylsiloxane) microchips. Talanta 71:2048–2055

Pan T, Kelly RT, Asplund MC, Woolley AT (2004) Fabrication of calcium fluoride capillary electrophoresis microdevices for on-chip infrared detection. J Chromatography A 1027:231–235

Jensen KF (2006) Silicon based microchemical systems—characteristics and applications. MRS Bull 31:101–107

Leung SA, Winkle RF, Wootton RCR, de Mello AJ (2005) A method for rapid reaction optimisation in continuous-flow microfluidic reactors using online Raman spectroscopic detection. Analyst 130:46–51

Lee M, Lee JP, Rhee H, Choo J, Chai YG, Lee EK (2003) Applicability of laser-induced Raman microscopy for in situ monitoring of imine formation in a glass microfluidic chip. J Raman Spectr 34:737–742

Salmon JB, Ajdari A, Tabeling P, Servant L, Talaga D, Joanicot M (2005) In situ Raman imaging of interdiffusion in a microchannel. Appl Phys Lett 86(9):094106

Liu GL, Lee LP (2005) Nanowell surface enhanced Raman scattering arrays fabricated by soft-lithography for label-free biomolecular detections in integrated microfluidics. Appl Phys Lett 87(7):074101

Docherty FT, Monaghan PB, Keir R, Graham D, Smith WE, Cooper JM (2004) The first SERRS multiplexing from labelled oligonucleotides in a microfluidics lab-on-a-chip. Chem Commun 1:118–119

Popp J, Tuchin VV, Chiou A, Heinemann SH (2012) Handbook of Biophotonics, vol 3. Wiley-VCH, Weinheim

Kazarian SG (2007) Enhancing high-throughput technology and microfluidics with FTIR spectroscopic imaging. Anal Bioanal Chem 388:529–532

Keybl J, Jensen KF (2011) Microreactor system for high-pressure continuous flow homogeneous catalysis measurements. Ind Eng Chem Res 50(19):11013–11022

Carter CF, Lange H, Ley SV, Baxendale IR, Wittkamp B, Goode JG, Gaunt NL (2010) ReactIR flow cell: a new analytical tool for continuous flow chemical processing. Org Proc Res Dev 14(2):393–404

Chan AKL, Gulati S, Edel JB, de Mello AJ, Kazarian SG (2009) Chemical imaging of microfluidic flows using ATR-FTIR spectroscopy. Lab Chip 9:2909–2913

Waldbaur A, Rapp H, Lange K, Rapp BE (2011) Let there be chip—towards rapid prototyping of microfluidic devices: one-step manufacturing processes. Anal Methods 3:2681–2716

Menz W, Mohr J, Paul O (2001) Microsystems technology. Wiley-VCH, Weinheim

Müller JJ, Neumann M, Scholl P, Hilterhaus L, Eckstein M, Thum O, Liese A (2010) Online monitoring of biotransformations in high viscous multiphase systems by means of FT-IR and chemometrics. Anal Chem 82(14):6008–6014

Müller J, Baum S, Hilterhaus L, Eckstein M, Thum O, Liese A (2011) Simultaneous determination of mono-, di- and triglycerides in multiphase systems by online FT-IR spectroscopy. Anal Chem 83(24):9321–9327

Gebhard J, Sellin D, Hilterhaus L, Liese A (2013) Online analysis of enzymatic polycondensation reactions in bubble column reactors by means of ATR-FTIR spectroscopy. Chem Ing Tech 85(7):1016–1022

Smith DY, Karstens W, Siles E, Inokuti M (2013) Defect and analysis effects in the infrared optical properties of silicon. Phys Status Solidi B 250(2):271–277

Kaufhold D, Fagaschewski J, Sellin D, Strompen S, Liese A, Hilterhaus L (2014) Novel μ-membrane module for online determination of the free fatty acid content in the dispersed phase of oil-in-water emulsions. Anal Bioanal Chem 406(13):3157–3166

Thomsen V, Schatzlein D, Mercuro D (2003) Limits of detection in spectroscopy. Spectroscopy 18(12):112–114

Gross E, Shu XZ, Alayoglu S, Bechtel HA, Martin MC, Toste FD, Somorjai GA (2014) In situ IR and X-ray high spatial-resolution microspectroscopy measurements of multistep organic transformation in flow microreactor catalyzed by Au nanoclusters. J Am Chem Soc 136:3624–3629

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Fagaschewski, J., Sellin, D., Wiedenhöfer, C. et al. Spatially resolved in situ determination of reaction progress using microfluidic systems and FT-IR spectroscopy as a tool for biocatalytic process development. Bioprocess Biosyst Eng 38, 1399–1405 (2015). https://doi.org/10.1007/s00449-015-1381-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-015-1381-z