Abstract

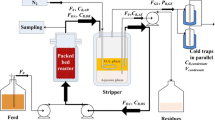

Acetone butanol ethanol (ABE) was produced in an integrated continuous one-stage fermentation and gas stripping product recovery system using Clostridium beijerinckii BA101 and fermentation gases (CO2 and H2). In this system, the bioreactor was fed with a concentrated sugar solution (250–500 g L−1 glucose). The bioreactor was bled semi-continuously to avoid accumulation of inhibitory chemicals and products. The continuous system was operated for 504 h (21 days) after which the fermentation was intentionally terminated. The bioreactor produced 461.3 g ABE from 1,125.0 g total sugar in 1 L culture volume as compared to a control batch process in which 18.4 g ABE was produced from 47.3 g sugar. These results demonstrate that ABE fermentation can be operated in an integrated continuous one-stage fermentation and product recovery system for a long period of time, if butanol and other microbial metabolites in the bioreactor are kept below threshold of toxicity.

Similar content being viewed by others

References

Dürre P (1998) New insights and novel developments in clostridial acetone/butanol/isopropanol fermentation. Appl Microbiol Biotechnol 49:639–648

Qureshi N, Saha BC, Dien BS, Hector RE, Cotta MA (2010) Production of butanol (a biofuel) from agricultural residues: Part I—use of barley straw hydrolysate. Biomass Bioenergy 34:559–565

Ezeji TC, Blaschek HP (2007) Biofuel from butanol: advances in genetic and physiological manipulation of clostridia. BioWorld Europe 2:12–15

Anon (2007) Biobutanol on the horizon. Chem Eng Prog March issue, pp 10

Ezeji TC, Qureshi N, Blaschek HP (2004) Acetone butanol ethanol (ABE) production from concentrated substrate: reduction in substrate inhibition by fed-batch technique and product inhibition by gas stripping. Appl Microbiol Biotechnol 63:653–658

Cheryan M, Mehaia MA (1983) A high-performance membrane bioreactor for continuous fermentation of lactose to ethanol. Biotechnol Lett 5:519–524

Mehaia MA, Cheryan M (1986) Lactic acid from acid whey permeate in a membrane recycle bioreactor. Enzym Microb Technol 8:289–292

Afschar AS, Biebl H, Schaller K, Schugerl K (1985) Production of acetone and butanol by Clostridium acetobutylicum in continuous culture with cell recycle. Appl Microbiol Biotechnol 22:394–398

Pierrot P, Fick M, Engasser JM (1986) Continuous acetone–butanol fermentation with high productivity by cell ultrafiltration and recycling. Biotechnol Lett 8:253–256

Qureshi N, Schripsema J, Lienhardt J, Blaschek HP (2000) Continuous solvent production by Clostridium beijerinckii BA101 immobilized by adsorption onto brick. World J Microbiol Biotechnol 16:377–382

Huang W-C, Ramey DE, Yang S-T (2004) Continuous production of butanol by Clostridium acetobutylicum immobilized in a fibrous bed bioreactor. Appl Biochem Biotechnol 113–116:887–898

Maddox IS (1989) The acetone-butanol-ethanol fermentation: recent progress in technology. Biotechnol Genetic Eng Rev 7:190–220

Groot WJ, van der Lans RGJM, Luyben KChAM (1989) Batch and continuous butanol fermentations with free cells: integration with product recovery by gas stripping. Appl Microbiol Biotechnol 32:305–308

Ezeji TC, Qureshi N, Blaschek HP (2005) Industrially relevant fermentations. In: Durre P (ed) Handbook on Clostridia. Taylor & Francis, New York, pp 797–812

Ennis BM, Marshall CT, Maddox IS, Paterson AHJ (1986) Continuous product recovery by in situ gas stripping/condensation during solvent production from whey permeate using Clostridium acetobutylicum. Biotechnol Lett 8:725–730

Mollah AH, Stuckey DC (1993) Feasibility of in situ stripping for continuous acetone-butanol fermentation by Clostridium acetobutylicum. Enz Microb Technol 15:200–207

Maddox IS, Qureshi N, Roberts-Thomson K (1995) Production of acetone–butanol–ethanol from concentrated substrates using Clostridium acetobutylicum in an integrated fermentation-product removal process. Process Biochem 30:209–215

Ezeji TC, Qureshi N, Blaschek HP (2003) Production of butanol by Clostridium beijerinckii BA101and in situ recovery by gas stripping. World J Microbiol Biotechnol 19:595–603

Qureshi N, Maddox IS, Friedl A (1992) Application of continuous substrate feeding to the ABE fermentation: relief of product inhibition using extraction, perstraction, stripping, and pervaporation. Biotechnol Prog 8:382–390

Annous BA, Blaschek HP (1991) Isolation and characterization of Clostridium acetobutylicum mutants with enhanced amylolytic activity. Appl Environ Microbiol 57:2544–2548

Qureshi N, Blaschek HP (1999) Butanol recovery from model solutions/fermentation broth by pervaporation: evaluation of membrane performance. Biomass Bioenergy 17:175–184

Qureshi N, Paterson AHJ, Maddox IS (1988) Model for continuous production of solvents from whey permeate in a packed bed reactor using cells of Clostridium acetobutylicum immobilized by adsorption onto bonechar. Appl Microbiol Biotechnol 29:323–328

Qureshi N, Lai LL, Blaschek HP (2004) Scale-up of a high productivity continuous biofilm reactor to produce butanol by adsorbed cells of Clostridium beijerinckii BA101. Trans Inst Chem Eng (Chem Eng Res Des) 82(C2):164–173

Ennis BM, Maddox IS, Schoutens GH (1986) Immobilized Clostridium acetobutylicum for continuous butanol production from whey permeate. New Zealand J Dairy Sci Technol 21:99–109

Ezeji TC, Karcher PM, Qureshi N, Blaschek HP (2005) Improving the performance of a gas stripping-based recovery system to remove butanol from Clostridium beijerinckii fermentation. Bioprocess Biosyst Eng 27:207–214

Lai MC, Traxler RW (1994) A coupled two-stage continuous fermentation for solvent production by Clostridium acetobutylicum. Enzym Microb Technol 16:1021–1025

Mulchandani A, Volesky B (1994) Production of acetone–butanol–ethanol by Clostridium acetobutylicum using a spin filter perfusion bioreactor. J Biotechnol 34:51–60

Acknowledgments

This research was supported by the Illinois Council on Food and Agricultural Research (C-FAR) grant numbers CFAR 0II-042-1 and IDA CF 01E-35-1; and in part by Northeast Sungrant (Cornell University) Award/Contract number GRT00012344. We would like to thank Michael A. Cotta (United States Department of Agriculture, National Center for Agricultural Utilization Research, Peoria, IL, USA) and Dr. James Kinder (Chair, Department of Animal Sciences, The Ohio State University) for reading this manuscript and providing critical comments.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Mention of trade names or commercial products in this article is solely for the purpose of providing scientific information and does not imply recommendation or endorsement by the U.S. Department of Agriculture. USDA is an equal opportunity provider and employer.

Rights and permissions

About this article

Cite this article

Ezeji, T.C., Qureshi, N. & Blaschek, H.P. Microbial production of a biofuel (acetone–butanol–ethanol) in a continuous bioreactor: impact of bleed and simultaneous product removal. Bioprocess Biosyst Eng 36, 109–116 (2013). https://doi.org/10.1007/s00449-012-0766-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-012-0766-5