Abstract

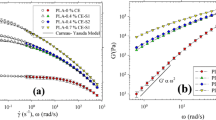

The rheological properties of a long chain branched polypropylene (LCB-PP) were investigated at the processing conditions of foam extrusion, namely high pressure, gas loading and high shear rates, as well as in elongational deformation. For measuring the rheological properties of PP at moderate and high deformation rates, an in-line rheometer was used. Comparison of the results to standard rotational rheometry showed good agreement. The effect of the processing parameters was quantified using shift factors for temperature, pressure and gas concentration. The influence of pressure on the shear viscosity was found to be of minor importance. In contrast, the shear viscosity was distinctly affected by CO2 concentration, reducing it to one third of its gas-free value at a concentration of 6 wt% at a specific shear rate. The change of viscosity by a variation of temperature is similar in magnitude compared to the variation due to dissolved blowing agent. Furthermore, thermo-rheological complex behaviour was observed. In the foaming process, thermo-rheological complexity could contribute to a better morphology control of long chain branched polymers compared to linear ones. The elongational viscosity was measured using both a hyperbolic die and a film stretching tool (UXF) for comparison. It is almost three decades higher than the shear viscosity in the non-linear region, due to pronounced strain hardening of the melt.

Similar content being viewed by others

References

Aho J, Syrjälä S (2010) Measurement of the pressure dependence of viscosity of polymer melts using a back pressure-regulated capillary rheometer. J Appl Polym Sci 117:1076–1084. doi:10.1002/app.31754

Arrhenius S (1889) Über die Reaktionsgeschwindigkeit bei der Inversion von Rohrzucker durch Säuren. Zeitschrift fuer Phys Chemie 4:226–248

Baird D, Huang J-C (2006) Elongational viscosity measurements using a semi-hyperbolic die. Appl Rheol 16:312

Barus C (1893) Isothermals, isopiestics, and isometrics relative to viscosity. Am J Sci 45:87–96

Borealis (2010) Daploy WB140HMS, Techn. report

Brinson HF, Brinson LC (2008) Polymer engineering science and viscoelasticity. Springer US, Boston, MA

Carella JM, Gotro JT, Graessley WW (1986) Thermorheological effects of long-chain branching in entangled polymer melts. Macromolecules 19:659–667. doi:10.1021/ma00157a031

Choudhary M (2005) Measurement of shear viscosity and solubility of polystyrene melts containing various blowing agents. J Cell Plast 41:589–599. doi:10.1177/0021955X05059036

Cogswell N (1972) Converging flow of polymer melts in extrusion dies

Collier JR, Petrovan S, Patil P (2003) Temperature shifting of convergent flow measured effective elongational viscosity. J Appl Polym Sci 87:1387–1396. doi:10.1002/app.11477

Collier JR, Petrovan S, Hudson N, Wei X (2007) Elongational rheology by different methods and orientation number. J Appl Polym Sci 105:3551–3561. doi:10.1002/app.26413

Doi M, Edwards SF (1986) The theory of polymer dynamics. Clarendon Press, Oxford, ISBN 0-19-852033–6

Doroudiani S, Kortschot MT (2003) Polystyrene foams. III Structure-tensile properties relationships J Appl Polym Sci 90:1427–1434. doi:10.1002/app.12806

Eckstein A, Suhm J, Friedrich C, et al. (1998) Determination of plateau moduli and entanglement molecular weights of isotactic, syndiotactic, and atactic polypropylenes synthesized with metallocene catalysts. 9297:1335–1340. doi: 10.1021/ma971270d

Fang H, Zhang Y, Bai J et al (2013) Bimodal architecture and rheological and foaming properties for gamma-irradiated long-chain branched polylactides. RSC Adv 3:8783–8795. doi:10.1039/c3ra40879e

Feng JJ, Bertelo C a (2004) Prediction of bubble growth and size distribution in polymer foaming based on a new heterogeneous nucleation model. J Rheol (N Y N Y) 48:439. doi:10.1122/1.1645518

Ferkl P, Pokorný R, Bobák M, Kosek J (2013) Heat transfer in one-dimensional micro- and nano-cellular foams. Chem Eng Sci 97:50–58. doi:10.1016/j.ces.2013.04.018

Ferri D, Lomellini P (1999) Melt rheology of randomly branched polystyrenes. J Rheol (N Y N Y) 43:1355. doi:10.1122/1.551048

Ferry JD (1950) Mechanical properties of substances of high molecular weight. VI Dispersion in Concentrated Polymer Solutions and its Dependence on Temperature and Concentration J Am Chem Soc 72:3746–3752. doi:10.1021/ja01164a117

Fujita H, Kishimoto A (1958) Diffusion-controlled stress relaxation in polymers. II Stress relaxation in swollen polymers J Polym Sci 28:547–567. doi:10.1002/pol.1958.1202811806

Gerhardt LJ, Garg A, Manke CW, Gulari E (1998) Concentration-dependent viscoelastic scaling models for Polydimethysiloxane melts with dissolved carbon dioxide. J Polym Sci Part B Polym Phys 36:1911–1918

Han CD (2007) Rheology and processing of polymeric materials volume 1: rheology

Handge UA, Altstädt V (2012) Viscoelastic properties of solutions of polystyrene melts and carbon dioxide: analysis of a transient shear rheology approach. J Rheol (N Y N Y) 56:743. doi:10.1122/1.4708601

Hasan MM, Li YG, Li G et al (2010) Determination of solubilities of CO2 in linear and branched polypropylene using a magnetic suspension balance and a PVT apparatus. J Chem Eng Data 55:4885–4895. doi:10.1021/je100488v

Keßner UM (2010) Thermorheology as a method to investigate the branching structures of Polyethylenes. Universität Erlangen-Nürnberg

Köppl T, Raps D, Altstädt V (2014) E-PBT—bead foaming of poly(butylene terephthalate) by underwater pelletizing. J Cell Plast 50:475–487. doi:10.1177/0021955X14528524

Kwag C, Manke CW, Gulari E (2001) Effects of dissolved gas on viscoelastic scaling and glass transition temperature of polystyrene melts. Ind Eng Chem Res 40:3048–3052. doi:10.1021/ie000680e

Ladin D, Park CB, Park SS et al (2001) Study of shear and extensional viscosities of biodegradable PBS/CO 2 solutions. J Cell Plast 37:109–148. doi:10.1106/72D3-9PX6-7C60-RD2X

Lee M, Tzoganakis C, Park CB (1998) Extrusion of PE/PS blends with supercritical carbon dioxide. Polym Eng Sci 38:1112–1120. doi:10.1002/pen.10278

Li YG, Park CB (2009) Effects of branching on the pressure−volume−temperature behaviors of PP/CO 2 solutions. Ind Eng Chem Res 48:6633–6640. doi:10.1021/ie8015279

Liu G, Sun H, Rangou S et al (2012) Studying the origin of “strain hardening”: basic difference between extension and shear. J Rheol 57:89–104. doi:10.1122/1.4763568

Malmberg A, Liimatta J, Lehtinen A, Löfgren B (1999) Characteristics of long chain branching in ethene polymerization with single site catalysts. Macromolecules 32:6687–6696. doi:10.1021/ma9907136

McCallum TJ, Kontopoulou M, Park CB et al (2007) The rheological and physical properties of linear and branched polypropylene blends. Polym Eng Sci 47:1133–1140. doi:10.1002/pen.20798

Münstedt H (2011) Rheological properties and molecular structure of polymer melts. Soft Matter 7:2273. doi:10.1039/c0sm00891e

Münstedt H, Laun HM (1979) Elongational behaviour of a low density polyethylene melt. Rheol Acta 18:492–504. doi:10.1007/BF01736955

Muzychka YS, Edge J (2008) Laminar non-Newtonian fluid flow in noncircular ducts and microchannels. J Fluids Eng 130:111201. doi:10.1115/1.2979005

Nobelen M, Hoppe S, Fonteix C et al (2006) Modeling of the rheological behavior of polyethylene/supercritical solutions. Chem Eng Sci 61:5334–5345. doi:10.1016/j.ces.2006.03.052

Park HE, Dealy JM (2006) Effects of pressure and supercritical fluids on the viscosity of polyethylene. Macromolecules 39:5438–5452. doi:10.1021/ma060735+

Rachtanapun P, Selke SEM, Matuana LM (2004) Relationship between cell morphology and impact strength of microcellular foamed high-density polyethylene/polypropylene blends. Polym Eng Sci 44:1551–1560. doi:10.1002/pen.20152

Ramesh NS, Lee ST (2000) Blowing agent effect on extensional viscosity calculated from fiber spinning method for foam processing. J Cell Plast 36:374–385. doi:10.1106/W3LI-MTQY-PJA9-RNJB

Raps D, Köppl T, de Anda AR, Altstädt V (2014) Rheological and crystallisation behaviour of high melt strength polypropylene under gas-loading. Polymer (Guildf) 55:1537–1545. doi:10.1016/j.polymer.2014.01.036

Resch J a, Keßner U, Stadler FJ (2011) Thermorheological behavior of polyethylene: a sensitive probe to molecular structure. Rheol Acta 50:559–575. doi:10.1007/s00397-011-0575-9

Rojo E, Muñoz ME, Santamaría A, Peña B (2004) Correlation between conformational parameters and rheological properties of molten syndiotactic polypropylenes. Macromol Rapid Commun 25:1314–1318. doi:10.1002/marc.200400138

Rouse PE (1953) A theory of the linear viscoelastic properties of dilute solutions of coiling polymers. J Chem Phys 21:1272. doi:10.1063/1.1699180

Royer JR, Gay YJ, Desimone JM, Khan S a (2000) High-pressure rheology of polystyrene melts plasticized with CO2: experimental measurement and predictive scaling relationships. J Polym Sci Part B Polym Phys 38:3168–3180. doi:10.1002/1099-0488(20001201)38:23<3168::AID-POLB170>3.0.CO;2-E

Royer JR, DeSimone JM, Khan SA (2001) High-pressure rheology and viscoelastic scaling predictions of polymer melts containing liquid and supercritical carbon dioxide. J Polym Sci Part B Polym Phys 39:3055–3066

Spitael P, Macosko CW (2004) Strain hardening in polypropylenes and its role in extrusion foaming. Polym Eng Sci 44:2090–2100. doi:10.1002/pen.20214

Stadler FJ, Piel C, Klimke K, et al. (2006) Influence of type and content of various comonomers on long-chain branching of ethene/R-olefin copolymers. 1474–1482.

Stadler FJ, Nishioka A, Stange J et al (2007) Comparison of the elongational behavior of various polyolefins in uniaxial and equibiaxial flows. Rheol Acta 46:1003–1012. doi:10.1007/s00397-007-0190-y

Stadler FJ, Kaschta J, Münstedt H (2008) Thermorheological behavior of various long-chain branched polyethylenes. Macromolecules 41:1328–1333. doi:10.1021/ma702367a

Stommel M, Stojek M, Korte W (2011) FEM zur Berechnung von Kunststoff- und Elastomerbauteilen. Carl Hanser Verlag

Takada M, Ohshima M (2003) Effect of CO2 on crystallization kinetics of poly(ethylene terephthalate). Polym Eng Sci 43:479–489. doi:10.1002/pen.10039

Venkatraman S, Okano M (1990) A comparison of torsional and capillary rheometry for polymer melts: the Cox-Merz rule revisited. Polym Eng Sci 30:308–313. doi:10.1002/pen.760300508

Wang J, James DF, Park CB, et al. (2008) Planar extensional viscosity of polystyrene and polystyrene CO2 solution. AIP Conference Proceedings. AIP, pp 81–83

Wang J, James DF, Park CB (2010) Planar extensional flow resistance of a foaming plastic. J Rheol (N Y N Y) 54:95–116. doi:10.1122/1.3257724

Wood-Adams P, Costeux S (2001) Thermorheological behavior of polyethylene: effects of microstructure and long chain branching. Macromolecules 34:6281–6290. doi:10.1021/ma0017034

Wood-Adams PM, Dealy JM, DeGroot AW, Redwine OD (2000) Effect of molecular structure on the linear viscoelastic behavior of polyethylene. Macromolecules 33:7489–7499. doi:10.1021/ma991533z

Xue A, Tzoganakis C (2003) Rheological properties of polystyrene/supercritical CO2 solutions from an extrusion slit die. J Polym Eng 23:1–22. doi:10.1515/POLYENG.2003.23.1.1

Yan D, Wang WJ, Zhu S (1999) Effect of long chain branching on rheological properties of metallocene polyethylene. Polymer (Guildf) 40:1737–1744. doi:10.1016/S0032-3861(98)00318-8

Yu K, Román Marín JM, Rasmussen HK, Hassager O (2010) 3D modeling of dual wind-up extensional rheometers. J Non-Newt Fluid Mech 165:14–23. doi:10.1016/j.jnnfm.2009.08.006

Zhang Z, Nawaby AV, Day M (2003) CO2-delayed crystallization of isotactic polypropylene: a kinetic study. J Polym Sci Part B Polym Phys 41:1518–1525. doi:10.1002/polb.10509

Acknowledgements

The financial support of the German Research Foundation (DFG) in the frame of the research project number Al 474/18-1 is highly acknowledged. We also thank PD Dr. Ulrich Handge, Dr. Sandra Aline Sanchez Vazquez and Prof. Hans-Martin Laun for numerous scientific discussions. Polypropylene was kindly provided by Borealis Polyolefine GmbH. We thank Sebastian Gröschel and Markus Schirmer for experimental support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Raps, D., Köppl, T., Heymann, L. et al. Rheological behaviour of a high-melt-strength polypropylene at elevated pressure and gas loading for foaming purposes. Rheol Acta 56, 95–111 (2017). https://doi.org/10.1007/s00397-016-0988-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00397-016-0988-6