Abstract

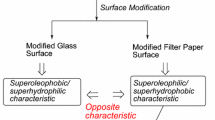

Fluoroalkyl end-capped vinyltrimethoxysilane oligomeric silica nanocomposites-encapsulated poly(acrylonitrile-co-butadiene) (NBR) [RF-(VM-SiO2) n -RF/NBR] were prepared by the sol-gel reactions of the corresponding oligomer [RF-(VM) n -RF] in the presence of NBR under alkaline conditions. Interestingly, it was demonstrated that these obtained fluorinated nanocomposites can afford no weight loss corresponding to the contents of NBR in the composites even after calcination at 800 °C. On the other hand, the nanocomposites, which were prepared under the cross-linking conditions at 150 °C for 30 min by using NBR containing zinc oxide and sulfur (S8) as the cure activator and the cross-linker, respectively, were found to exhibit a clear weight loss corresponding to the contents of the NBR after calcination at 800 °C. The fluoroalkyl end-capped oligomeric silica nanocomposites-encapsulated the cross-linked NBR were applied to the surface modification of glass to supply the superoleophilic/superhydrophobic characteristic on the surface. The nanocomposites possessing such superoleophilic/superhydrophobic characteristic were applied to the packing material for the column chromatography to separate not only the mixture of oil and water but also the W/O emulsion. In contrast, the nanocomposites, which were prepared under no cross-linking conditions, were not applicable to the packing materials for the separation of these mixtures due to the oleophilic characteristic of the encapsulated NBR in the nanocomposite cores.

Application of RF-(VM-SiO2) n -RF/NBRzn-s nanocomposites to the separation of oil and waterᅟ

Similar content being viewed by others

References

Sadhu S, Bhowmick AK (2004) J Polym Sci Part B: Polym Phys 42:1573–1585

Frounchi M, Mehrabzadeh M, Parvary M (2000) Polym Int 49:163–169

Choi S-S, Ha S-H (2010) J Ind Eng Chem 16:238–242

Kim J-T, Oh T-S, Lee D-H (2003) Polym Int 52:1058–1063

Kim J. T, Oh T-S, vLee D-H (2003) Polym Int 52:1203–1208

Kim JT, Oh T-S, Lee D-H (2004) Polym Int 53:406–411

Du W, Zou H, Tian M, Zhang L, Wang W (2012) Polym Adv Technol 23:1029–1035

Zhu S-H, Chan C-M, Wong SC, Mai Y-W (1999) Polym Eng Sci 39:1998–2006

Suzuki N, Ito M, Ono S (2005) J Appl Polym Sci 95:74–81

Yu P, He H, Jiang C, Jia Y, Wang D, Yao X, Jia D, Luo YJ (2016) Appl Polym Sci 1–10. doi:10.1002/app.42922

Vargese H, Bhagawan SS, Thomas S (1995) Eur Polym J 31:957–967

Bandyopadhyay GG, Bhagawan SS, Ninan KN, Thomas S (1997) Rubber Chem Technol 70:650–662

Pandey JK, Reddy KR, Kumar AP, Singh RO (2005) Polym Degrad Stab 88:234–250

Koshy AT, Kuriakose B, Thomas S (1992) Polym Degrad Stab 36:137–147

Lopes D, Ferreria MJ, Russo R, Dias JM (2015) J Clean Prod 92:230–236

Jansen P, oares BG (2001) J Appl Polym Sci 79:193–202

Ge X, Zhang Y, Deng F, Cho UR Polym Compos doi:10.1002/pc.23817

Ge X, Li M-C, Li XX, Cho UR (2015) Appl Clay Sci 118:265–275

Thomas PC, Jose ET, George G, Thomas S, Joseph K (2012) Polym Compos 33:2236–2244

H. Takahashi and H. Sawada (2006) United States Patent, US 7,144,962 B2

Sawada H, Matsuki Y, Goto Y, Kodama S, Sugiya M, Nishiyama Y (2010) Bull Chem Soc Jpn 83:75–81

Sawada H (2012) Polym Chem 3:46–65

Sawada H, Nakayama M (1991) J Chem Soc Chem Commun 677–678

Akiba M, Hashim AS (1997) Prog Polym Sci 22:475–521

Rahaman MSA, Ismail AF, Mustafa A (2007) Polym Degrad Stab 92:1421–1432

Xiao S, Wang B, Zhao C, Xu L, Chen B (2013) J Appl Polym Sci 127:2332–2338

Sivy GT, Gordon B, Coleman MM (1983) Carbon 21:573–578

Xiao S, Cao W, Wang B, Xu L, Chen B (2013) J Appl Polym Sci 127:3198–3203

Sawada H, Kabutomori M, Ratcha A, Kongparakul S, Nishida M (2016) Colloid Polym Sci. 294:1173–1186

Oikawa Y, Saito T, Yamada S, Sugiya M, Sawada H (2015) ACS Appl Mater Interfaces 7:13782–13793

Saito T, Tsushima Y, Sawada H (2015) Colloid Poym Sci 293:65–73

Li J, Wan H, Ye Y, Zhou H, Chen J (2012) Appl Surf Sci 261:470–472

Zhang M, Wang C, Wang S, Shi Y, Li J (2012) Appl Surf Sci 261:764–769

Zhang M, Wang C, Wang S, Shi Y, Li J (2013) Carbohydr Polym 97:59–64

Arbatan T, Zhang L, Fang X-Y, Shen W (2012) Chem Eng J 210:74–79

Si Y, Guo Z (2015) Chem Lett 44:874–883

Liu K, Tian Y, Jiang L (2013) Prog Mater Sci 58:503–564

Darmanin T, Guittard F (2014) Prog Polym Sci 39:656–682

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Funding

This work was partially supported by a Grant-in-Aid for Scientific Research 16 K05891 from the Ministry of Education, Science, Sports, and Culture, Japan.

Conflict of Interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Ratcha, A., Saito, T., Takahashi, R. et al. Preparation and thermal stability of fluoroalkyl end-capped vinyltrimethoxysilane oligomeric silica/poly(acrylonitrile-co-butadiene) nanocomposites—application to the separation of oil and water. Colloid Polym Sci 294, 1529–1539 (2016). https://doi.org/10.1007/s00396-016-3909-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-016-3909-4