Abstract

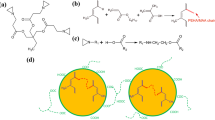

Grafting reactions between different acrylates (methyl, ethyl, butyl, hexyl, and lauryl) and natural rubber latex (NRL) were performed in miniemulsion. It is observed that polyacrylates with longer alkyl chain length, i.e., ≥4 carbons, only produce stable dispersions with the hydrophobic azo initiator 2,2′-azobis(2-methylbutyronitrile) (V59). Increasing the reaction temperature from 5 to 72 °C with different initiating systems increases the gel content of the butyl acrylate (BA)-modified NRL. Solid-state 1H MAS NMR was employed to accurately calculate the grafting efficiency of polyacrylate-modified NRL. Initiating systems such as 2,2′-azobis(4-methoxy-2.4-dimethyl valeronitrile) (V70) and cumene hydroperoxide yield the maximum grafting of ∼53 wt.% efficiency of BA (compared to the BA used) on NRL whereas an enzyme initiator yields the lowest grafting efficiency of 18.3 wt.%. The reaction with V59 as initiator shows the intermediate grafting efficiency of 37 wt.%. Increasing the BA amount from 16.4 to 26.6 wt.% increases the gel content to 47 and 68 wt.%, respectively. The grafting efficiency of BA on NRL is constant at ∼35 wt.% for BA contents from 16.4 to 22.7 wt.%, but for further increasing BA amount to 27 wt.%, a 3.7 times higher grafting efficiency of BA on NRL was observed compared to the other two lower concentrations of BA. Film-forming properties and DSC analysis were used to investigate the phase behavior of polyacrylate-blended and grafted NRL materials; transmission electron microscopy was used to investigate the morphology of BA-grafted NRL.

Similar content being viewed by others

References

Arayapranee W, Rempel GLJ (2008) Appl Polym Sci 109:1395–1402

Daniel D, Punyanich I, Ngoc TQ, Frédéric G, Charoen N (2009) Eur Polym J 45:820–836

Lee D-Y, Subramaniam N, Fellows CM, Gilbert RGJ (2002) Polym Sci A Polym Chem 40:809–822

Oliveiraa PC, Guimaraes A, Cavaille J-Y, Chazeauc L, Gilbertb RG, Santosa AM (2005) Polymer 46:1105–1111

Bielawski CW, Jethmalani JM, Grubbs RH (2003) Polymer 44:3721–3726

Schneider M, Pith T, Lambla MJ (1996) Appl Polym Sci 62:273–290

Landfester K (2006) Annu Rev Mater Res 36:231–279

Landfester K (2009) Angew Chem Int Edit 48:4488–4507

Brandrup J, Immergut EH, Grulke EA (1999) Polymer Handbook, 4th ed, Wiley

Alger MSM (1989) Polymer science dictionary. Elsevier, London

Choi KJ, Lee GH, Ahn SJ, Shon KH, Kim I, Jeong HMJ (1996) Appl Polym Sci 59:557–560

Machado JM, Lee CS (1994) Polym Eng Sci 34:59–68

Zachariah O, Sabu T (1993) Polym Bull 31:623–628

Subramaniam N, Simpson A, Monteiro MJ, Shaffer O, Fellows CM, Gilbert RG (2004) Microscop Res Tech 63:111–114

Jing P, Maolin W, Jinliang Q, Genshuan W (2005) Rad Phys Chem 72:739–743

Jin KK, Won CH, Jong YK (2003) Eur Polym J 39:1249–1265

Author information

Authors and Affiliations

Corresponding author

Additional information

An erratum to this article can be found at http://dx.doi.org/10.1007/s00396-011-2409-9

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Ragupathy, L., Ziener, U., Robert, G. et al. Grafting polyacrylates on natural rubber latex by miniemulsion polymerization. Colloid Polym Sci 289, 229–235 (2011). https://doi.org/10.1007/s00396-010-2360-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-010-2360-1