Abstract

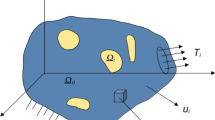

In view of code verification of finite element implementations and for material parameter identification purposes it is of interest to make use of stress algorithms developed for three-dimensional finite element computations. In the case of homogeneous deformations various boundary-conditions for given displacements or stresses are possible and define a sub-problem of three-dimensional stress–strain states, which are either one-, two- or three-dimensional. Examples are uniaxial tension/compression, plane stress conditions or biaxial tensile problems. Caused by the fact that the stress algorithms are strain-driven, the constraints of zero stresses in a specific direction lead for elastic and inelastic constitutive models to a particular system of differential-algebraic equations. How to treat such stress algorithms and how to solve the resulting system of differential-algebraic equations, which are developed for finite element programs, for specific stress and displacement boundary conditions is discussed in this article. Additionally, it is worked out that the consistent tangent operator is required in the same manner as in 3D-FE computations. The second topic treats the extension of the entire procedure for material parameter identification procedure applied to test data for different materials such as steel, rubber material and powder. In this respect, uniaxial tensile, biaxial tensile tests, and laterally constrained loading paths are exemplarily investigated. These investigations and the proposed procedure are applied for small and finite strain problems. In this investigation measure of the quality of identification is discussed as well.

Similar content being viewed by others

References

Andresen K, Dannemeyer S, Friebe H, Mahnken R, Ritter R, Stein E (1996) Parameteridentifikation für ein plastisches Stoffgesetz mit FE-Methoden und Rasterverfahren. Bauingenieur 71:21–31

Anscombe FJ (1973) Graphs in statistical analysis. Am Stat 27(1):17–21. http://www.jstor.org/stable/2682899

Armstrong PJ, Frederick CO (1966) A mathematical representation of the multiaxial Bauschinger effect. Tech. Rep. General Electricity Generating Board, Report No.: RD/B/N731, Berceley Nuclear Laboratories

Ascher UM, Petzold LR (1998) Computer methods for ordinary differential equations and differential-algebraic equations. SIAM Society for Industrial and Applied Mathematics, Philadelphia

Beck JV, Arnold KJ (1977) Parameter estimation in engineering and science. Wiley, New York

Benedix U, Görke UJ, Kreißig R, Kretzschmar S (1998) Local and global analysis of inhomogeneous displacement fields for the identification of material parameters. In: Hoa SV, De Wilde WP, Blain WR (eds) Computer methods in composite materials VI (CADCOMP 98), pp 159–168

Bier W, Hartmann S (2006) A finite strain constitutive model for metal powder compaction using a unique and convex single surface yield function. Eur J Mech Series A Solids 25:1009–1030

Bier W, Dariel MP, Frage N, Hartmann S, Michailov O (2007) Die compaction of copper powder designed for material parameter identification. Int J Mech Sci 49:766–777

Brandt S (1999) Datenanalyse, 4th edn. Spektrum, Akademischer Verlag, Heidelberg

Chaboche JL, Rousselier G (1983) On the plastic and viscoplastic constitutive equations—part I. Rules developed with internal variable concept. J Pressure Vessel Technol 105:153–158

Coleman T, Li Y (1996) An interior trust region approach for nonlinear minimization subject to bounds. SIAM J Optim 6(2):418–445. doi:10.1137/0806023

Dennis JE, Schnabel Rb (1996) Numerical methods for unconstrained optimiziation and nonlinear equations, 2nd edn. Society for industrial and Applied Mathematics, Philadelphia

Ellsiepen P, Hartmann S (2001) Remarks on the interpretation of current non-linear finite-element-analyses as differential-algebraic equations. Int J Numer Methods Eng 51:679–707

Gill PE, Murray W, Wright MH (1981) Practical optimization. Academic Press, London

Hairer E, Wanner G (1996) Solving ordinary differential equations II, 2nd edn. Springer, Berlin

Hairer E, Norsett SP, Wanner G (1993) Solving ordinary differential equations I, 2nd edn. Springer, Berlin

Hartmann S (1993) Lösung von Randwertaufgaben der Elastoplastizität. Ein Finite-Elemente-Konzept für nichtlineare kinematische Verfestigung bei kleinen und finiten Verzerrungen. Doctoral thesis, Institute of Mechanics, University of Kassel, Report No. 1/1993

Hartmann S (1998a) Nichtlineare Finite-Elemente-Berechnung angewendet auf ein Viskoplastizitätsmodell mit Überspannungen. In: Hartmann S, Tsakmakis C (eds) Aspekte der Kontinuumsmechanik und Materialtheorie. Gesamthochschul-Bibliothek Verlag, Kassel, pp 55–80

Hartmann S (1998b) Zur Berechnung inelastischer Festkörper mit der Methode der finiten Elemente. In: Hartmann S, Haupt P, Ulbricht V (eds) Modellierung und Identifikation. Gesamthochschul-Bibliothek, Kassel, pp 119–130

Hartmann S (2001) Numerical studies on the identification of the material parameters of Rivlin’s hyperelasticity using tension-torsion tests. Acta Mech 148:129–155

Hartmann S (2002) Computation in finite strain viscoelasticity: finite elements based on the interpretation as differential-algebraic equations. Comput Methods Appl Mech Eng 191(13–14):1439–1470

Hartmann S (2005) A remark on the application of the Newton–Raphson method in non-linear finite element analysis. Comput Mech 36(2):100–116

Hartmann S, Bier W (2008) High-order time integration applied to metal powder plasticity. Int J Plasticity 24(1):17–54

Hartmann S, Haupt P (1993) Stress computation and consistent tangent operator using non-linear kinematic hardening models. Int J Numer Methods Eng 36:3801–3814

Hartmann S, Neff P (2003) Polyconvexity of generalized polynomial-type hyperelastic strain energy functions for near-incompressibility. Int J Solids Struct 40(11):2767–2791

Hartmann S, Lührs G, Haupt P (1997) An efficient stress algorithm with applications in viscoplasticity and plasticity. Int J Numer Methods Eng 40:991–1013

Hartmann S, Kamlah M, Koch A (1998) Numerical aspects of a non-proportional cyclic plasticity model under plane stress conditions. Int J Numer Methods Eng 42:1477–1498

Hartmann S, Haupt P, Tschöpe T (2001) Parameter identification with a direct search method using finite elements. In: Besdo D, Schuster R, Ihlemann J (eds) Constitutive models of rubber II. Balkema, Lisse, pp 249–256

Hartmann S, Tschöpe T, Schreiber L, Haupt P (2003) Large deformations of a carbon black-filled rubber. Experiment, optical measurement and parameter identification using finite elements. Eur J Mech Ser A Solids 22:309–324

Hartmann S, Gibmeier J, Scholtes B (2006) Experiments and material parameter identification using finite elements. Uniaxial tests and validation using instrumented indentation tests. Exp Mech 46(1):5–18

Hartmann S, Quint KJ, Arnold M (2008) On plastic incompressibility within time-adaptive finite elements combined with projection techniques. Comput Methods Appl Mech Eng 198:178–193

Hartmann S, Kuhl D, Quint KJ (2009) Time-adaptive computation of thermoviscoplastic structures. In: Steinhoff K, Maier HJ, Biermann D (eds) Functionally graded materials in industrial mass production, chap 3.1. Verlag Wissenschaftliche Scripten, Auerbach (Germany), pp 269 – 282

Hedderich J, Sachs L (2012) Angewandte Statistik, 14th edn. Springer, Heidelberg

Hoyer W, Schmidt JW (1984) Newton-type decomposition methods for equations arising in network analysis. ZAMM Zeitschrift für Angewandte Mathematik und Mechanik 64:397–405

Huber N, Tsakmakis C (1999a) Determination of constitutive properties from spherical indentation data using neural networks, Part I: plasticity with nonlinear and kinematic hardening. J Mech Phys Solids 47:1589–1607

Huber N, Tsakmakis C (1999b) Determination of constitutive properties from spherical indentation data using neural networks, part II: the case of pure kinematic hardening in plasticity laws. J Mech Phys Solids 47:1569–1588

Johansson M, Mahnken R, Runesson K (1999) Efficient integration technique for generalized viscoplasticity coupled to damage. Int J Numer Methods Eng 44:1727–1747

Kreisselmeier G, Steinhauser R (1979) Systematische Auslegung von Reglern durch Optimierung eines vektoriellen Gütekriteriums. Regelungstechnik 3:76–79

Kreißig R (1998) Auswertung inhomogener Verschiebungsfelder zur Identifikation der Parameter elastisch-plastischer Deformationsgesetze. Forschung im Ingenieurwesen 64:99–109

Kreissig R, Benedix U, Goerke UJ (2001) Statistical aspects of the identification of material parameters for elasto-plastic models. Arch Appl Mech 71:123–134

Lion A (2001) Thermomechanically consistent formulations of the standard linear solid using fractional derivatives. Arch Mech 53:253–273

Mahnken R (1998) Theoretische und numerische Aspekte zur Parameteridentifikation und Modellierung bei metallischen Werkstoffen. Tech. Rep. No. F98/2, Institut für Baumechanik und Numerische Mechanik, Universität Hannover, Hannover, Germany

Mahnken R, Stein E (1996) A unified approach for parameter identification of inelastic material models in the frame of the finite element method. Comput Methods Appl Mech Eng 136:225–258

Mahnken R, Johansson M, Runesson K (1998) Parameter estimation for a viscoplastic damage model using gradient-based optimization algorithm. Eng Comput 15(7):925–955

Nocedal J, Wright SJ (1999) Numerical optimization. Springer, New York

Perzyna P (1966) Fundamental problems in viscoplasticity. Adv Appl Mech 9:243–377

Quint K (2012) Thermomechanically coupled processes for functionally graded materials: Experiments, modelling, and finite element analysis using high-order dirk-methods. PhD thesis, Clausthal University of Technology

Rabbat NBG, Sangiovanni-Vincentelli AL, Hsieh HY (1979) A multilevel Newton algorithm with macromodeling and latency for the analysis of large-scale nonlinear circuits in the time domain. IEEE Trans Circuits Syst 26:733–740

Rothe S, Hamkar AW, Quint KJ, Hartmann S (2012) Comparison of diagonal-implicit, linear-implicit and half-explicit Runge-Kutta methods in non-linear finite element analyses. Arch Appl Mech 82(8):1057 – 1074

Scheday G (2003) Theorie und Numerik der Parameteridentifikation von Materialmodellen der finiten Elastizität und Inelastizität auf der Grundlage optischer Feldmessmethoden. Phd-thesis, Report No. I-11 (2003), University of Stuttgart (Germany), Institute of Mechanics

Simo JC, Taylor RL (1985) Consistent tangent operators for rate-independent elastoplasticity. Comput Methods Appl Mech Eng 48:101–118

Spellucci P (1999) DONLP2 short users guide. Tech. rep., Department of Mathematics, TU Darmstadt

Steinmann P, Hossain M, Possart G (2012) Hyperelastic models for rubber-like materials: consistent tangent operators and suitability for treloars data. Arch Appl Mech 82:1183–1217. doi:10.1007/s00419-012-0610-z

Strehmel K, Weiner R (1995) Numerik gewöhnlicher Differentialgleichungen. Teubner Verlag, Stuttgart

Tarantola A (2005) Inverse problem theory and methods for model parameter estimation. SIAM Society for Industrial and Applied Mathematics, Philadelphia

Thielecke F (1998) Parameteridentifizierung von Simulationsmodellen für das viskoplastische Verhalten von Metallen - Theorie, Numerik, Anwendung. Dissertation, Braunschweiger Schriften zur Mechanik, Nr. 34-1998, TU Braunschweig

Treloar LRG (1975) The physics of rubber elasticity, 3rd edn. Clarendon Press, Oxford

Acknowledgments

We would like to thank the German Research Foundation (DFG) for supporting this work under the Grant No. HA2024/7-1.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

1.1 Appendix 1: Filter matrices

In this section the filter matrices \({{\bf{\mathsf{Z}}}_1}\) and \({{\bf{\mathsf{Z}}}_2}\), see, for example, in Eq. (22), for several loading cases are assembled.

1D-tension/compression—strain control

1D-tension/compression—stress control

Torsion of thin-walled tube—small strain case

Plane strain case

Plane stress case

Compression laterally constrained—stretch driven

Compression laterally constrained—stress control

Equibiaxial—stress control

1.2 Appendix 2: Analytical solution of parameter identification in J 2-plasticity

To determine a possibility of material parameter identification for the J 2-visco-plasticity model (78)–(82) in the rate-independent limit we have the three-dimensional model

with the yield condition

For the uniaxial tensile test one has the strain

and stress state T = σ (e 1 ⊗ e 1) and X = ξ (e 1 ⊗ e 1) − (ξ/2) (e 2 ⊗ e 2 + e 3 ⊗ e 3).

Under uniaxial uniaxial tension for \(\sigma(t) = \dot{\sigma} t + k\), where k is the yield stress \((\dot{\sigma} =\hbox{const.} > 0)\), the following scalar equations result from Eqs. (105)–(108):

λ is obtained by the consistence condition \(\dot{f} = 0\). In this stress-controlled process with the initial conditions \(\varepsilon_{\rm p}(0) = 0\) and ξ(0) = 0 one calculates by Eq. (107)

Now, the total strains can be written as

for \(\varepsilon=k/E\). Inversion of Eq. (119) and application to the strain-controlled case yields

This implicit equation can be solved for every given strain \(\varepsilon\). Furthermore, it can be differentiated in respect to \(\varepsilon\) to get a possibility for computing the material parameters b and c. The slopes at the yield point and at the final state σ 0′ and σ 1′ can be derived from the measured stress–strain relation

i.e. the material parameters b and c are quantifiable, see Eq. (86). Figure 7 shows the slopes and the values of a typical diagram. Obviously, b and c are not independent on each other, see Eq. (86)2.

Rights and permissions

About this article

Cite this article

Krämer, S., Rothe, S. & Hartmann, S. Homogeneous stress–strain states computed by 3D-stress algorithms of FE-codes: application to material parameter identification. Engineering with Computers 31, 141–159 (2015). https://doi.org/10.1007/s00366-013-0337-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00366-013-0337-7