Abstract

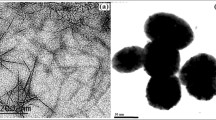

In this work, radio frequency shielding behaviour of polymer (epoxy) matrixes composed of E-glass fibres and Fe2O3 fillers have been studied. The principal aim of this project is to prepare suitable shielding material for RFID application. When RFID unit is pasted on a metal plate without shielding material, the sensing distance is reduced, resulting in a less than useful RFID system. To improve RF shielding of epoxy, fibres and fillers were utilized. Magnetic behaviour of epoxy polymer composites was measured by hysteresis graphs (B-H) followed by radio frequency identifier setup. Fe2O3 particles of sizes 800, 200 and 100 nm and E-glass fibre woven mat of 600 g/m2 were used to make composites. Particle sizes of 800 nm and 200 nm were prepared by high-energy ball milling, whereas particles of 100 nm were prepared by sol–gel method. To enhance better dispersion of particles within the epoxy matrix, a surface modification process was carried out on fillers by an amino functional coupling agent called 3-Aminopropyltrimethoxysilane (APTMS). Crystalline and functional groups of siliconized Fe2O3 particles were characterized by XRD and FTIR spectroscopy analysis. Variable quantity of E-glass fibre (25, 35, and 45 vol%) was laid down along with 0.5 and 1.0 vol% of 800, 200, and 100 nm size Fe2O3 particles into the matrix, to fabricate the hybrid composites. Scanning electron microscopy and transmission electron microscopy images reveal the shape and size of Fe2O3 particles for different milling times and particle dispersion in the epoxy matrix. The maximum improved sensing distance of 45.2, 39.4 and 43.5 % was observed for low-, high-, and ultra-high radio frequency identifier setup along with shielding composite consist of epoxy, 1 vol% 200 nm Fe2O3 particles and 45 vol% of E-glass fibre.

Similar content being viewed by others

References

V.R. Arunprakash, A. Rajadurai, Mechanical, thermal and dielectric characterization of iron(III)oxide reinforced epoxy hybrid composite. Dig. J. Nanomater. Biostruct. 11, 373–380 (2016)

K. Jagadeesan, A. Ramasamy, A. Das, Electromagnetic shielding behaviour of conductive filler composites and conductive fabrics. Indian J. Fibres Text 39, 329–342 (2014)

T.P. Yadav, R.M. Yadav, Mechanical milling a top down approach for the synthesis of nanomaterials and nanocomposites. Nanosci. Nanotechnol. 2(3), 22–48 (2012)

M. Mohapatra, S. Anand, Synthesis and applications of nano-structured iron oxides and hydroxides—a review. Int. J. Eng. Sci. Technol. 2(8), 127–146 (2010)

L.I.U. Dong-hua, L.I.U. Yong, Effect of ball milling time on microstructures and mechanical properties of mechanically alloyed iron based material. Trans Non-ferr. Metals 20, 831–838 (2010)

M. Mohapatra, S. Anand, Synthesis and applications of nano-structured iron oxides and hydroxides—a review. Int. J. Eng. Sci. Technol. 2(8), 127–146 (2010)

H. Arami, KM. Krishnan, Highly stable amine functionalized iron oxide nano particles designed for magnetic particle imaging. IEEE Trans. Magn. Mater. 49(7), 3500–3503 (2011)

Zhanhu Guo, Kenny Lei, Yutong Li, Thomas Hahn, Fabrication and characterization of iron oxide nanoparticls reinforced vinyl-ester resin nanocomposites. Compos. Sci. Technol. 68, 1513–1520 (2008)

V.R. Arun prakash, A. Rajadurai, Thermo-mechanical characterization of siliconized E-glass fiber/Hematite particles reinforced epoxy resin hybrid composite. Appl. Surf. Sci. 384, 99–106 (2016)

D.D.L. Chung, Electromagnetic interference shielding effectiveness of carbon material. Carbon 39, 279–285 (2001)

N. Dvurechenskaya, P.R. Bajurko, Measurements of shielding effectiveness of textile materials containing metal by the free-space transmission technique with data processing in the time domain. Metrol. Meas. Syst. XX(2), 217–228 (2013)

Anupama joshi and suwarna datar, Carbon nanostructure composite for electromagnetic interference shielding. Indian Acad Sci. 84, 6 (2015)

S. Layek, A. Pandye, Synthesis of γ- and α-Fe2O3 nano particles and magnetic textures. Int. J. Eng. Sci. Technol 2(8), 33–39 (2010)

Xiaohuan Wang, Investigation of electromagnetic scielding effectiveness of nano structural carbon black/ABS composite. J. Electromagn. Anal. Appl. 3, 160–164 (2011)

M. Sabri Özen, Investigation of the electromagnetic shielding effectiveness of carded and needled bonded non woven fabrics produced at different ratios at conductive steel fibres. J. Eng. Fibres Fabr. 10, 849–858 (2015)

T.W. Więckowski, Methods of evaluating shielding effectiveness of textiles. Fibres Text. Res Estern Europe 14(05(59)), 18–22 (2006)

Acknowledgments

The authors gratefully acknowledge the work rendered from Dr.V. Jerome das professor, Department of Physics, Loyola College, Chennai, India.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Arun prakash, V.R., Rajadurai, A. Radio frequency shielding behaviour of silane treated Fe2O3/E-glass fibre reinforced epoxy hybrid composite. Appl. Phys. A 122, 875 (2016). https://doi.org/10.1007/s00339-016-0411-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-016-0411-2