Abstract

In this investigation, we used high-speed shadow photography to observe fast optodynamic phenomena such as shock waves and the ablation of flat metal surfaces. These phenomena were induced in air by a Q-switched Nd:YAG laser (λ = 1,064 nm) with a pulse duration of 4 ns and an excitation pulse energy between 10 and 55 mJ. For a good spatial resolution of the shadowgraphs, we used short illumination pulses (30 ps) from a frequency-doubled Nd:YAG laser (λ = 532 nm). Using the shadowgraphs of the shock wave expansion into a half-space, we measured the optodynamic energy conversion efficiency, defined as the ratio between the mechanical energy of the shock wave and the excitation pulse energy. This efficiency increases with an increasing excitation pulse energy. We also present the characteristic shadowgraphs of the ablation of a black-painted metal surface, where the macroscopic material particles are clearly visible. They follow the shock wave and eventually overtake it. As a result, the shape of the shock wave, which normally expands concentrically into the half-space, has an altered form. The presented results reveal the phenomenon of the laser ablation of coated metal surfaces.

Similar content being viewed by others

1 Introduction

The pulsed-laser ablation of surfaces is of a great importance in a laser-induced material transfer [1–3], pulsed-laser deposition [4–6], cleaning of the metal surfaces [7] and ablation of tissue in various medical applications [8, 9]. Here, the interaction between the laser pulse and the coated or uncoated surface induces different optodynamic phenomena [10], such as ablated material ejection [2], and—in gasses—also the shock and acoustic wave expansion [11, 12]. The main goal of this contribution is to examine the optodynamic phenomena in air using a shadow photography, which makes it possible to observe the local differences in the refractive index of transparent materials [13] as well as the regions with ablated particles, which significantly increase the local absorption of the illumination probe.

From the time-resolved shadowgraphs of the shock wave, we are able to obtain its radius as a function of time. These measurements enable an estimation of its mechanical energy using the Jones model [14]. Thus, we can estimate the optodynamic (OD) energy conversion efficiency, defined as the ratio between the energy of the shock wave and the excitation pulse energy [11, 15]. We also present the measured dynamics of the shock wave as well as of the ablated particles for the case of the interaction between a high-intensity laser pulse and a coated metal surface. Here, we discuss the interaction between the ejected particles and the shock wave.

2 Materials and methods

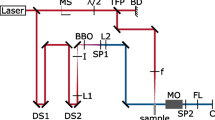

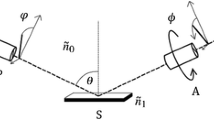

The experimental setup is shown in Fig. 1. The laser-induced breakdown was induced in air by a Q-switched Nd:YAG laser (λ = 1,064 nm, Quantel, France, Brio). The excitation laser has a pulse duration of 4 ns (FWHM). The pulse is partially deflected onto a fast, 1-GHz photodiode (PD1) using a dielectric plate (DP), which reflects approximately 8 % of the incident light. We were also using a variable attenuator (A1; attenuation range 2–98 %). The light, reflected by the attenuator, was irradiated on the energy meter (EM). In this way, we simultaneously measured the excitation pulse energy. During our experiments we used pulse energies in the range 10–55 mJ. The excitation pulse passes through a beam expander (BE) and a lens (L) with a focal length of 100 mm. The excitation pulse spot diameter was measured by microscope from the single-shot spot size and was 50 μm at the point of the interaction, i.e., on the front surface of the metal sample. Thus, intensities in the range 1–7 × 1015 W m−2 induced plasma, followed by a shock wave (SW) expansion.

The metal sample was held by a motorized positioning system with a resolution of 1 μm that enables movement in all three dimensions. This allowed us to move the sample during the measurements, so that each time a fresh patch of surface was ablated. For the samples we used clean steel plates (dimensions 60 × 10 × 0.5 mm) as well as coated steel plates (dimensions 80 × 70 × 0.95 mm). For the coating we used a black acrylic paint, which was applied on the front surface of the sample. The thickness of the coating was in around 35 μm. The positioning system was tilted by ~5° to avoid any back reflection that could damage the exciting laser.

The shadowgraph system uses a doubled-frequency Nd:YAG laser (EKSPLA, Lithuania, PL-2250-SH-TH) emitting green illumination pulses (λ = 532 nm) with a pulse duration (FWHM) of 30 ps. Using a mirror (M) the pulses are directed through an attenuator (A2), consisting of a half-wave plate (HWP), a polarizing beam-splitter (PBS), and a beam dump (BD). Afterwards, the illumination pulse passes another dielectric plate (DP) that reflects a part of the pulse (~8 %) onto a fast, 1-GHz photodiode (PD2). A beam expander (BE) was used to expand the illumination pulse by a factor of 10. In such a way, a short illumination of the whole excitation pulse–material interaction area was achieved. A narrow band-pass filter (BPF, 532 ± 10 nm) is placed in front of the microscope to block the light that is emitted by the laser-induced plasma. The microscope is used to set the magnification and the focus onto the place of the interaction. The shadowgraph images were acquired with a CCD camera (Basler AG, Germany, scA1400-17 fm, 1,392 × 1,040 px). The lasers and cameras were synchronized by a digital signal generator (SG; Tektronix, US, AFG 3102, 1GS/s, 100 MHz) with two channels (CH1 and CH2) and connected to a personal computer.

The time delay between the lasers can be set by SG in the range from 1 ns to 2 µs with a resolution of 1 ns. The actual delay between the excitation and the illumination pulse is affected by jitter of the triggering system, which is ±6 ns, and measured from the signals of both fast photodiodes (PD1 and PD2), acquired by an oscilloscope (LeCroy, US, 600 MHzWave Runner 64MXi-A) with a sampling rate of 10 GS/s. The whole experiment is controlled by custom-made software that also enables image and data acquisition as well as the image and data processing. For each event we acquired two shadowgraphs: (1) the shadowgraph of the background (before the irradiation by an excitation pulse); and (2) the shadowgraph of the optodynamic phenomena, also called the active image. By subtracting the background image from the active one, only the relevant visual information is retained.

3 Results and discussion

3.1 Optodynamic energy conversion efficiency

Typical shadowgraphs of a shock wave, induced by the interaction between the excitation pulse and the clean metal surface in air, are presented in Fig. 2. In this particular case, the laser pulse energy was 43 mJ. The time after the laser-induced breakdown is shown on the top-right-hand side of each image, while the scale is shown below the image B1. On each image, the ablated sample is outlined with dashed lines. The sample was tilted intentionally by ~5° to prevent any back reflection of the excitation laser light. The shock wave expands spherically into a half-space with a gradually decreasing velocity.

A series of typical shock wave images captured with high-speed shadowgraphy. The average energy of the excitation pulses, incident from the right, was 43 mJ. The time delay between the excitation and the illumination pulse is shown on the top-right-hand side of each frame. The scale is shown below image B1

From typical shadowgraphs, shown in Fig. 2, we determined the shock wave’s radius as a function of time. This radius was measured by fitting a circle on the front of the shock wave. These qualitative results, obtained at an excitation pulse energy of 43 mJ, are presented in Fig. 3. From this shock wave propagation, the energy of the shock wave, E 0, can be determined using the Jones model [14], which is an extension of the Taylor model [16, 17] for strong shock waves. While the Taylor model has the wrong limit in the region of weak shock waves, the Jones model is an approximation that is applicable to the whole range of shock wave dynamics, i.e., from the region of strong waves to the region of acoustic waves. In our previous work [18, 19], it has been shown that this model is appropriate for determination of energy of the laser-induced shock wave. This is also confirmed by current results, namely, by a good fit of the Jones model to the experimental data (e.g., compare the solid blue curve and the orange points in Fig. 3).

Time-resolved shock wave radius (the orange points) for the excitation pulse energy E 0 = 43 mJ. The fitted Jones model [Eq. (1)] is shown by the solid blue curve. The shock wave energy, obtained as a fitted parameter, is E 0 = 6.2 mJ

The solid blue curve in Fig. 3 is a fit of the Jones model, defined by the equation [14]:

Here, t stands for the time, c 0 = 346 m/s is the speed of sound in air for ambient conditions (T = 25 °C, p 0 = 105 Pa) and R C is the characteristic radius, defined as [14]:

In Eq. (2), E 0 stands for the shock wave energy, γ = 1.4 is the adiabatic index of the gas and p 0 = 105 Pa is the ambient pressure. The \( \lambda_{S}^{5} = 2.35 \) stands for the dimensionless geometry-dependent parameter for the half-space expansion [17].

From the fit of Eq. (1) to the experimental data using the least-squares method, we obtained the energy of the shock waves that were induced by excitation pulses with different energies. The fitted energies, E 0, for different excitation pulse energies, E L, are presented in Table 1. This table also lists the OD energy conversion efficiencies η, defined as:

Figure 4 presents the OD energy conversion efficiency as a function of the excitation pulse energy. For an excitation pulse energy E L = 36 mJ, the fitted shock wave energy is E 0 = 6.2 mJ. Thus, the OD energy conversion efficiency in this case equals 17 %, and it decreases with a decreasing pulse energy, as is clear from Fig. 4. This decreasing is reasonable, since in the limit, i.e., when the excitation pulse intensity is lower than the threshold intensity for the plasma formation, all the excitation pulse energy is either reflected or absorbed and converted into the heat. Due to this reason, the OD energy conversion efficiency should go to zero by decreasing the pulse intensity. On the other hand, by increasing the excitation pulse energy this efficiency approaches 18 %. This value is in a good agreement with the results obtained by Diaci et al. [11], who measured this efficiency using a multiple laser beam deflection probe. They also came to similar conclusions, i.e., that the OD energy conversion efficiency increases with an increasing pulse energy, until it reaches a maximum value. We believe that this maximum value results from the fact, that at intensities much higher than the threshold intensity only a negligible part of the pulse energy is lost (due to reflection or conversion into the heat due to absorption) before the plasma formation. A similar phenomena, presented in Fig. 4, i.e., that the OD energy conversion efficiency increases by intensity, is observed in different media with different laser sources, e.g., see Ref. [13].

The average propagation velocity of the shock wave on the segment can be calculated from two successive radii. From the measurements presented in Fig. 2 and Fig. 3, it can be concluded that in this case the shock wave velocity 60 ns after the optical breakdown is 3.6 km/s, while a few hundred nanoseconds later, i.e., at 490 ns after the explosion, it is 0.7 km/s, and it converges to the speed of sound in air, i.e., c 0 = 0.346 km/s for ambient conditions (p 0 = 105 Pa, T 0 = 25 °C).

From the measured shock wave velocities v, the shock wave pressure p can be calculated as [8]:

Using Eq. (4), it can be concluded from the measured velocities that the shock wave pressure 60 ns after the optical breakdown is 130 × 105 bar, while 490 ns after the excitation pulse it equals 5 × 105 bar, and it approaches to the ambient pressure, p 0 = 105 Pa.

3.2 Visualization of the ablated particles

Figure 5 shows a series of typical images for optodynamic phenomena that appear in the case when a high-intensity laser pulse is focused on the black-painted metal surface in air. To ensure repeatable conditions, the sample was moved by a positioning system after each excitation laser pulse so that all the laser–material interactions took place on a fresh patch of the surface. Each time only one shadowgraph image was acquired using different time delays between the illumination and excitation pulses.

A series of typical shadowgraph images of shock waves and particles ablated during the excitation pulse interaction with the coated metal surface. The average energy of the excitation pulses, incident from the right, was 53 mJ. The time delay is shown on the top-right-hand side of each image, while the scale is shown below image B1

The ablated particles are visible as darker pixels on the images A2–B5 in Fig. 5. In the first 550 ns (images A2–A5) the particles follow the front of the blast wave. In our particular case, the paint particles overtake the front of the shock wave 650 ns after the optical breakdown (e.g., see image B1). At that moment the shock wave loses its spherical shape, since its wave front is interrupted by the particles’ penetration. When the particles overtake the shock wave, they cease traveling in a compact cloud, but instead travel in a more dispersed manner. The fact that the flyer material reaches the shock front is somehow surprising. However, a similar phenomenon was also noticed by Mattle et al. [2]. This happens because the shock wave velocity decreases faster than the particle velocity.

4 Conclusions

Using high-speed shadow photography, we measured the dynamics of a shock wave induced during the interaction between a high-intensity laser pulse and a metal plate in air. We described how this shock wave propagates at the front side of the plate. From the acquired shadowgraphs we measured the radius of the shock wave as a function of time. These measurements were further used to calculate the shock wave energy using the Jones model. We have found that the OD energy conversion efficiency, i.e., the part of the excitation pulse energy that is converted into the mechanical energy of the shock wave, is in the range between 12 and 18 % for nanosecond excitation pulse energies between 10 and 50 mJ.

We have also presented typical images of the shock wave, induced by an irradiated metal plate with a black-painted surface. In this case, we observed the particles’ ablation. We have shown that the paint particles overtake the shockwave’s front and affect its shape.

References

J. Bohandy, B.F. Kim, F.J. Adrian, J. Appl. Phys. 60, 1538 (1986)

T. Mattle, J. Shaw-Stewart, A. Hintennach, C.W. Schneider, T. Lippert, A. Wokaun, Appl. Surf. Sci. 278, 77 (2012)

M. Feinaeugle, A.P. Alloncle, Ph Delaporte, C.L. Sones, R.W. Eason, Appl. Surf. Sci. 258, 8475 (2012)

J.G. Lunney, Appl. Surf. Sci. 86, 79 (1995)

C. Sánchez-Aké, R. Camacho, L. Moreno, J. Appl. Phys. 112, 044904 (2012)

F. Guzman, M. Favre, H.M. Ruiz, S. Hevia, L.S. Caballero, E.S. Wyndham, H. Bhuyan, M. Flores, S. Mandl, J. Phys. D 46, 215202 (2013)

G.M. Bilmes, D.J.O. Orzi, O.E. Martínez, A. Lencina, Appl. Phys. B 82, 643 (2006)

A. Vogel, K. Lorenz, V. Horneffer, G. Hüttmann, D. von Smolinski, A. Gebert, Biophys. J. 93, 4481 (2007)

L. Kuščer, J. Diaci, J. Biomed. Opt. 18, 108002 (2013)

J. Možina, J. Diaci, Appl. Phys. B 105, 557 (2011)

J. Diaci, J. Možina, J. Phys. IV 4, 737 (1994)

G. Bosiger, T. Perhavec, J. Diaci, S. Vestnik, Strojniški Vestnik—J. Mech. Eng. 60, 172 (2014)

G.S. Settles, Schlieren and shadowgraph techniques (Springer-Verlag, Berlin, 2001)

D.L. Jones, Phys. Fluids 11, 1664 (1968)

P. Gregorčič, M. Jezeršek, J. Možina, J. Biomed. Opt. 17, 075006 (2012)

G. Taylor, P. Roy, Soc. Lond. A Mat. 202, 159 (1950)

G. Taylor, P. Roy, Soc. Lond. A Mat. 201, 175 (1950)

P. Gregorčič, J. Možina, Opt. Lett. 36, 2782 (2011)

P. Gregorčič, J. Diaci, J. Možina, Appl. Phys. A 112, 49 (2013)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gregorčič, P., Zadravec, J., Možina, J. et al. Optodynamic energy conversion efficiency during laser ablation on metal surfaces measured by shadow photography. Appl. Phys. A 117, 353–357 (2014). https://doi.org/10.1007/s00339-014-8412-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-014-8412-5