Abstract

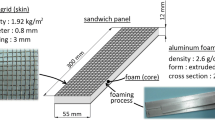

The goal of the present work is the variation of the structure of aluminum integral foams regarding the thickness of the integral solid skin as well as the density profile. A modified die casting process, namely integral foam molding, is used in which an aluminum melt and blowing agent particles (magnesium hydride MgH2) are injected in a permanent steel mold. The high solidification rates at the cooled walls of the mold lead to the formation of a solid skin. In the inner region, hydrogen is released by thermal decomposition of MgH2 particles. Thus, the pore formation takes place parallel to the continuing solidification of the melt. The thickness of the solid skin and the density profile of the core strongly depend on the interplay between solidification velocity and kinetics of hydrogen release. By varying the melt and blowing agent properties, the structure of integral foams can be systematically changed to meet the requirements of the desired field of application of the produced component.

Similar content being viewed by others

References

C. Körner, R.F. Singer, Adv. Eng. Mater. 2, 4 (2000)

H. Wiehler, Prozessentwicklung des Hochdruckintegralschaumgießens von Aluminium, PhD Thesis, University of Erlangen-Nuremberg, 2010

H.-W. Seeliger, Adv. Eng. Mater. 4, 10 (2002)

A. Trepper, Niederdruck-Integralschaumgießen—Technologie für Aluminiumgussteile mit reduziertem Körperschall, PhD Thesis, University of Erlangen-Nuremberg, 2010

C. Körner, Integral foam molding of light metals: technology, foam physics and foam simulation (Springer, Berlin, 2008)

H. Wiehler, C. Körner, R.F. Singer, Adv. Eng. Mater. 10, 3 (2008)

J. Hartmann, A. Trepper, C. Körner, Adv. Eng. Mater. 13, 11 (2011)

J.F. Fernández, C.R. Sánchez, J. Alloys Compd. 340, 1–2 (2002)

P. Wang, A.M. Wang, Y.L. Wang, H.F. Zhang, Z.Q. Hu, Scripta Mater. 43, 1 (2000)

A. Andreasen, M.B. Sørensen, R. Burkarl, B. Møller, A.M. Molenbroek, A.S. Pedersen, J.W. Andreasen, M.M. Nielsen, T.R. Jensen, J. Alloys Compd. 404–406, Spec. Iss., 323–326 (2005)

T.R. Jensen, A. Andreasen, T. Vegge, J.W. Andreasen, K. Ståhl, A.S. Pedersen, M.M. Nielsen, A.M. Molenbroek, F. Besenbacher, Int. J. Hydrogen Energ. 31, 14 (2006)

R.A. Varin, S. Li, A. Calka, J. Alloys Compd. 376, 1–2 (2004)

B. Matijasevic-Lux, J. Banhart, S. Fiechter, O. Görke, N. Wanderka, Acta Mater. 54, 7 (2006)

B. Matijasevic-Lux, J. Banhart, Scripta Mater. 54(4), Spec. Iss. (2006)

G. Barkhordarian, T. Klassen, R. Bormann, J. Alloys Compd. 407, 1–2 (2006)

A. Zaluska, L. Zaluski, J.O. Ström-Olsen, J. Alloys Compd. 289, 1–2 (1999)

A. Borgschulte, M. Bielmann, A. Züttel, G. Barkhordarian, M. Dornheim, R. Bormann, Appl. Surf. Sci. 254, 8 (2008)

G. Stepura, V. Rosenband, A. Gany, J. Alloys Compd. 513, 159–164 (2012)

R.A. Varin, T. Czujko, Ch. Chiu, Z. Wronski, J. Alloys Compd. 424, 1–2 (2006)

C.W. Ostenfeld, I. Chorkendorff, Surf. Sci. 600, 6 (2006)

M. Dornheim, S. Doppiu, G. Barkhordarian, U. Boesenberg, T. Klassen, O. Gutfleisch, R. Bormann, Scripta Mater. 56, 10 (2007)

R.L. Corey, T.M. Ivancic, D.T. Shane, E.A. Carl, R.C. Bowman Jr, J.M. Bellosta von Colbe, M. Dornheim, R. Bormann, J. Huot, R. Zidan, A.C. Stowe, M.S. Conradi, J. Phys. Chem. C 112, 49 (2008)

G. Liang, J. Huot, S. Boily, A. Van Neste, R. Schulz, J. Alloys Compd. 292, 1–2 (1999)

W. Oelerich, T. Klassen, R. Bormann, J. Alloys Compd. 315, 1–2 (2001)

H.G. Schimmel, M.R. Johnson, G.J. Kearley, A.J. Ramirez-Cuesta, J. Huot, F.M. Mulder, J. Alloys Compd. 393, 1–2 (2005)

O. Friedrichs, J.C. Sánchez-López, C. López-Cartes, M. Dornheim, T. Klassen, R. Bormann, A. Fernández, Appl. Surf. Sci. 252, 6 (2006)

C.-H. Chao, T.-C- Jen, Appl. Mech. Mater. 302, 151–157 (2013)

A. Zaluska, L. Zaluski, J.O. Ström-Olsen, J. Alloys Compd. 288, 1–2 (1999)

I. Halikia, P. Neou-Syngouna, D. Kolitsa, Thermochim. Acta 320, 1–2 (1998)

S. Otarawanna, C.M. Gourlay, H.I. Laukli, A.K. Dahle, Metall. Mater. Trans. A 40, 7 (2009)

W. Fragner, H. Kaufmann, Druckgusspraxis 1, 29–33 (2005)

M. Bünck, E. Schaberger-Zimmermann, E. Breuer, B. Lao, A. Bührig-Polaczek, Giesserei 10 (2012)

J.F. Fernández, C.R. Sánchez, J. Alloys Compd. 356–357, 348–352 (2003)

Acknowledgments

The authors gratefully acknowledge the financial support of the Deutsche Forschungsgemeinschaft (DFG), grant no. KO 1984/5-2. The authors also thank Dr. Andreas Borgschulte, EMPA, for his help and expertise concerning the decomposition behavior of magnesium hydride and Dr. Ralf Rettig for providing the Thermo-Calc calculations.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hartmann, J., Fiegl, T. & Körner, C. Aluminum integral foams with tailored density profile by adapted blowing agents. Appl. Phys. A 115, 651–660 (2014). https://doi.org/10.1007/s00339-014-8377-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-014-8377-4