Abstract

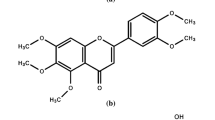

By combining the advantages of the molecular imprinting technique and the membrane separation technique, molecularly imprinted membranes (MIMs) were studied to separate special target molecule—kaempferol, an important active pharmaceutical ingredient. The kaempferol MIMs were prepared by the liquid–solid phase inversion method. The effects of organic additives (normal propyl alcohol, PEG-400, PEG-1000 and PVP-K30) on gelation kinetics and kaempferol MIM properties were studied. Results showed that normal propyl alcohol and PEG-400 could generate micropores and accelerate the gelation speed, so the membranes had high rejection and low water flux. Different with both of them, when PEG-1000 or PVP-K30 were used, the membranes had the great water flux, and their gelation speed were slower than the above two. Normal propyl alcohol and PEG-1000 were picked to make MIMs and tested the influence to kaempferol MIM properties. It was shown that MIM which added PEG-1000 had the maximum adsorption equilibrium compared with which added normal propyl alcohol, blank-additive MIM and non-MIM for its high water flux, it was 549.7 μg/g, but high water flux could reduce its separation factor, the separation factor of MIMs which added PEG-1000 and normal propyl alcohol were 3.90 and 4.17, respectively.

Similar content being viewed by others

References

Wulff G, Sarhan A (1972) Über die Anwendung von enzymanalog gebauten Polymeren zur Racemattrennung. Angew Chem 84(8):364

Wulff G, Sarhan A, Zabrocki K (1973) Enzyme-analogue built polymers and their use for the resolution of racemates. Tetrahedron Lett 14(44):4329–4332

Ang QY, Zolkeflay MH, Low SC (2016) Configuration control on the shape memory stiffness of molecularly imprinted polymer for specific uptake of creatinine. Appl Surf Sci 369:326–333

Ulbricht M (2004) Membrane separations using molecularly imprinted polymers. J Chromatogr B 804(1):113–125

Hao MY, Xiao-Ling HU, Guan P, Yang F (2007) Review of preparation of molecularly imprinted membrane. Chinese Polm Bull 33(6):8–14

Lee JW, Park JK (2005) Selective separations using molecularly imprinted membranes. Korean J Biotechnol Bioeng 20(3):372–378

Miean KH, Mohamed S (2001) Flavonoid (myricetin, quercetin, kaempferol, luteolin, and apigenin) content of edible tropical plants. J Agr Food Chem 49(6):3106–3112

Hakkinen SH, Karenlampi SO, Heinonen IM, Mykkanen HM, Torronen AR (1999) Content of the flavonols quercetin, myricetin, and kaempferol in 25 edible berries. J Agr Food Chem 47(6):2274–2279

Olszewska M (2008) Separation of quercetin, sexangularetin, kaempferol and isorhamnetin for simultaneous HPLC determination of flavonoid aglycones in inflorescences, leaves and fruits of three Sorbus species. J Pharmaceut Biomed 48(3):629–635

Li B, Xu Y, Jin Y-X, Wu Y-Y, Tu Y-Y (2010) Response surface optimization of supercritical fluid extraction of kaempferol glycosides from tea seed cake. Ind Crop Prod 32(2):123–128

Piletsky SA, Dubey IY, Fedoryak DM, Kukhar VP (1990) Substrate-selective polymeric membranes. Selective transfer of nucleic acids component. Biopolym Cell 6(5):55–58

Renkecz T, László K, Horváth V (2012) In situ synthesis of molecularly imprinted nanoparticles in porous support membranes using high-viscosity polymerization solvents. J Mol Recognit Jmr 25(6):320–329

Yoshikawa M, Izumi JI, Kitao T (1999) Alternative molecular imprinting, a facile way to introduce chiral recognition sites. React Funct Polym 42(1):93–102

Abdel-Shafy HI, Sayour HE, Mansour MSM (2015) Molecular imprinted membrane based on molecular imprinted nanoparticles polymer for separation of polycyclic aromatic hydrocarbons. Polym Adv Technol 27(6):724–732. doi:10.1002/pat.3704

Kobayashi T (1998) Molecular imprinted membranes prepared by phase inversion of polyacrylonitrile copolymers containing carboxylic acid groups. Acs Symp 703:188–201

He Z, Meng M, Yan L, Zhu W, Sun F, Yan Y, Liu Y, Liu S (2015) Fabrication of new cellulose acetate blend imprinted membrane assisted with ionic liquid ([BMIM]Cl) for selective adsorption of salicylic acid from industrial wastewater. Sep Purif Technol 145:63–74

Donato L, Tasselli F, Drioli E (2010) Molecularly imprinted membranes with affinity properties for folic acid. Sep Sci Technol 45(16):2273–2279

Yuxin MA, Shi F, Jun MA, Miaonan WU, Zhang J, Gao C (2011) Effect of PEG additive on the morphology and performance of polysulfone ultrafiltration membranes. Desalination 272(1):51–58

Pei L, Zhang L (2010) Improvement of hydrophilicity of porous PVDF membranes with LiCl additives. J Southeast Univ 26(2):201–204

Hester JF, Banerjee P, Won YY, Akthakul A, Acar MH, Mayes AM (2002) ATRP of amphiphilic graft copolymers based on PVDF and their use as membrane additives. Macromolecules 35(20):7652–7661

Kim IC, Jeong BR, Kim SJ, Lee KH (2013) Preparation of high flux thin film composite polyamide membrane: the effect of alkyl phosphate additives during interfacial polymerization. Desalination 308(6):111–114

Ahmad AL, Abdulkarim AA, Ooi BS, Ismail S (2013) Recent development in additives modifications of polyethersulfone membrane for flux enhancement. Chem Eng J 223(5):246–267

Lei X, Ding X, Jinying HE, Wang L, Leijing SU, Yongzhen WU, Wei Y, Wang G (2000) Effects of additives on characterization and performance of polysulfone ultrafiltration membrane. Acta Bot Sin 42(11):1144–1149

Huang Z, Zhang P, Yun Y (2017) Preparing molecularly imprinted membranes by phase inversion to separate kaempferol. Polym Adv Technol 28(3):373–378. doi:10.1002/pat.3898

Acknowledgements

This work was financially supported by the “National Science Foundation of China (Grant No. 21376030)”.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huang, Z., Xia, Q. & Yun, Y. Effects of different organic additives on kaempferol molecularly imprinted membrane properties. Polym. Bull. 75, 441–452 (2018). https://doi.org/10.1007/s00289-017-2044-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-017-2044-9