Abstract

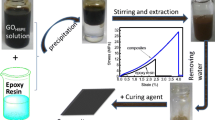

Polyurethane acrylate (PUA) and o-cresol formaldehyde epoxy resin (o-CFER) is synthesized. The PUA/o-CFER glass fiber-reinforced composites cured by free radical/cationic ring-opening reaction are modified by the reducing graphene oxide (r-GO). Effect of r-GO on the thermal and mechanical properties of PUA/o-CFER glass fiber-reinforced composites are characterized by FTIR, DMA and TGA. The result of FTIR shows that the system has cured completely. DMA analysis indicates that this system has better compatibility, and the glass transition temperature (T g) decreases with increasing r-GO content. TGA analysis shows that the initial thermal degradation temperature (T id) and activation energy (E a) enhance 13.1 °C and 3.12 kJ/mol, respectively. The tensile and impact strength of glass fiber-reinforced composites are approximately 50 and 60 % higher than those without r-GO. It is shown that the r-GO can enhance the mechanical properties and thermal stability of composites.

Similar content being viewed by others

References

Syurik J, Alyabyeva N, Alekseev A, Ageev OA (2014) AFM-based model of percolation in graphene-based polymer nanocomposites. Compos Sci Technol 95(1):38–43

Dutta S, Pati SK (2010) Novel properties of graphene nanoribbons: a review. J Mater Chem 20(38):8207–8223

Park OK, Hwang JY, Goh M, Lee JH, Ku BC, You NH (2013) Mechanically strong and multifunctional polyimide nanocomposites using amimophenyl functionalized graphene nanosheets. Macromolecules 46(9):3505–3511

Martin-Gallegoa M, Verdejo R, Lopez-Manchado MA, Sangermano M (2011) Epoxy-graphene UV-cured nanocomposites. Polymer 52(21):4664–4669

Norazlina H, Kamal Y (2015) Graphene modifications in polylactic acid nanocomposites: a review. Polym Bull 72(4):931–961

Cen Zeng C, Lu SR, Xiao X, Gao J, Pan LI, He ZH, Yu JH (2015) Enhanced thermal and mechanical properties of epoxy composites by mixing noncovalently functionalized graphene sheets. Polym Bull 72(3):453–472

Manafi P, Ghasemi I, Karrabi M, Azizi H, Manafi MR, Ehsaninamin P (2015) Thermal stability and thermal degradation kinetics (model-free kinetics) of nanocomposites based on poly (lactic acid)/graphene: the influence of functionalization. Polym Bull 72(5):1095–1112

Okada H, Tokunaga T, Liu X, Takayanagi S, Matsushima A, Shimohigashi Y (2008) Direct evidence revealing structural elements essential for the high binding ability of bisphenol A to human estrogen-related receptor-γ. Environ Heal Persp 116(1):32–38

Vom SFS, Myers JP (2008) Bisphenol A and risk of metabolic disorders. JAMA 300:1353–1355

Vom SFS, Hughes C (2005) An extensive new literature concerning low-dose effects of bisphenol A shows the need for a new risk assessment. Environ Heal Persp 113(3):926–933

Gao JG, Kong DJ, Zhao HC, Li SR (2011) Curing kinetics, thermal, mechanical, and dielectric properties based on o-cresol formaldehyde epoxy resin with polyhedral oligomeric (N-aminoethyl-γ-amino propyl)silsesquioxane. Polym Adv Technol 22(10):1395–1402

Yao HS, Liu WQ, Hou MH, Shen DY (2005) Study of epoxy polysiloxane modified o-cresol formaldehyde epoxy resins. China Plast 19(1):29–33

Crivello JV, Lam JHW (1977) Diaryliodonium salts. a new class of photoinitiators for cationic polymerization. Macromolecules 10(6):1307–1315

Hou GX, Gao JG, Tian C (2013) Hybrid free radical-cationic thermal polymerization of methylacryloylpropyl-POSS/epoxy resins nanocomposites. J Polym Res 20(8):221–230

Harald H, Abdelkrim E, Ulrich SS (2004) Free radical and thermal curing of terpyridine modified terpolymers. J Polym Sci Part A 42(16):4028–4035

Datta J (2010) Synthesis and investigation of glycolysates and obtained polyurethane elastomers. J Elastom Plast 42(2):117–127

Datta J, Kacprzyk M (2008) Thermal analysis and static strength of polyurethanes obtained from glycolysates. J Thermal Anal Calorim 93(3):753–757

Kostrzewa M, Hausnerova B, Bakar M, Dalka M (2011) Property evaluation and structure analysis of polyurethane/epoxy graft interpenetrating polymer networks. J Appl Polym Sci 122(3):1722–1730

Li JB (2006) High performance epoxy resin nanocomposites containing both organic montmorillonite and castor oil-polyurethane. Polym Bull 56(4):377–384

Sow C, Riedl B, Blanchet P (2011) UV-waterborne polyurethane-acrylate nano-composite coatings containing alumina and silica nanoparticles for wood: mechanical, optical, and thermal properties assessment. J Coat Technol Res 8(2):211–221

Lin J, Yang QZ, Wen XF, Cai ZQ, Pi P, Chen J, Yang ZR (2011) Synthesis, characterization, and thermal stability studies of bisphenol-A type novolac epoxy-polyurethane coating systems for in-mould decoration ink applications. J Polym Res 18(6):1667–1677

Vabrk R, Czajlil I, Túry C, Ruszna I, Ille A, Vig A (1998) A study of epoxy resin-acrylated polyurethane semi-interpenetrating polymer networks. J Appl Polym Sci 68(1):111–119

Shi YC, Wu YS, Zhu ZQ (2003) Modification of aqueous acrylic–polyurethane via epoxy resin postcrosslinking. J Appl Polym Sci 88(2):470–475

Prolongo SG, Jimenez-Suarez A, Moriche R, Ureña A (2013) In situ processing of epoxy composites reinforced with graphene nanoplatelets. Compos Sci Technol 86(9):185–191

Hodlur RM, Rabinal MK (2014) Self assembled graphene layers on polyurethane foam as a highly pressure sensitive conducting composite. Compos Sci Technol 90(1):160–165

King JA, Klimek DR, Miskioglu I, Odegard GM (2013) Mechanical properties of graphene nanoplatelet/epoxy composites. J Appl Polym Sci 128(6):4217–4223

Crivello JV (1979) Photoinitiators. US Patent: 4,136,102

Hummers WS Jr, Offeman RE (1958) Preparation of graphitic oxide. J Amer Chem Soci 80(6):1339

Park S, An J, Potts JR, Velamakanni A, Murali S, Ruoff RS (2011) Hydrazine reduction of graphite- and graphene oxide. Carbon 49(9):3019–3023

Wang H, Hu YH (2011) Effect of oxygen content on structures of graphite oxides. Ind Eng Chem Res 50(10):6132–6137

Shin HJ, Kim KK, Benayad A, Yoon SM (2009) Efficient reduction of graphite oxide by sodium borohydride and its effect on electrical conductance. Adv Funct Mater 19(12):1987–1992

Achaby ME, Essamlali Y, Miri NE, Snik A, Abdelouahdi K, Fihri A, Zahouily M, Solhy A (2014) Mechanically strong nanocomposite films based on highly filled carboxymethyl cellulose with graphene oxide. J Appl Polym Sci. doi:10.1002/app.41042

Gillham JK (1997) The TBA torsion pendulum: a technique for characterizing the cure and properties of thermosetting systems. Polym Int 44(2):262–276

Brandalise RN, Zeni M, Martins JDN, Forte MMC (2009) Morphology, mechanical and dynamic mechanical properties of recycled high density polyethylene and poly (vinyl alcohol) blends. Polym Bull 62(1):33–43

Kostrzewa M, Hausnerova B, Bakar M, Pająk K (2011) Preparation and characterization of an epoxy resin modified by a combination of MDI-based polyurethane and montmorillonite. J Appl Polym Sci 122(5):3237–3247

Wu GH, Gu J, Zhao X (2007) Preparation and dynamic mechanical properties of polyurethane-modified epoxy composites filled with functionalized fly ash particulates. J Appl Polym Sci 105(3):1118–1126

Yu B, Wang X, Xing WY, Yang HG, Song L, Hu Y (2012) UV-curable functionalized graphene oxide/polyurethane acrylate nanocomposite coatings with enhanced thermal stability and mechanical properties. Ind Eng Chem Res 51(45):14629–14636

Zhu D, Pignatello JJ (2005) Characterization of aromatic compound adsorptive interactions with black carbon (charcoal) assisted by graphite as a model. Environ Sci Technol 39(9):2033–2041

Lin D, Xing B (2008) Tannic acid adsorption and its role for stabilizing carbon nanotube suspensions. Environ Sci Technol 42(16):5917–5923

Ogata M, Kinjo N, Kawata T (1993) Effects of crosslinking on physical properties of phenol- formaldehyde novolac cured epoxy resins. J Appl Polym Sci 48(1):583–601

Jeong HK, Lee YP, Jin MH, Kim ES, Bae JJ, Lee YH (2009) Thermal stability of graphite oxide. Chem Phys Lett 470(4):255–258

Hsu SH, Wu MC, Chen S (2012) Synthesis, morphology and physical properties of multi-walled carbon nanotube/biphenyl liquid crystalline epoxy composites. Carbon 50(3):896–905

Cao XX, Gao JG, Dai X, Liu YF, He XF (2012) Kinetics of thermal degradation of nanometer calcium carbonate/linear low-density polyethylene nanocomposites. J Appl Polym Sci 126:1159–1164

Jin FL, Park SJ (2012) Thermal properties of epoxy resin/filler hybrid composites. Polym Degrad Stabil 97(11):2148–2153

Friedman HL (1964) Kinetics of thermal degradation of char-forming plastics from thermogravimetry. Application to a phenolic plastic. J Polym Sci C 6(1):183–195

Mahesh KPO, Alagar M, Jothibasu S (2006) A comparative study on the preparation and characterization of aromatic and aliphatic bismaleimides-modified polyurethane–epoxy interpenetrating polymer network matrices. J Appl Polym Sci 99(6):3592–3602

Lee JK, Song S, Kim B (2012) Functionalized graphene sheets-epoxy based nanocomposite for cryotank composite application. Polym Compos 33(8):1263–1273

Acknowledgments

The authors gratefully acknowledge the High Level Talents Foundation (No. A201400504) of Hebei Province, China.

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Han, H., Jiang, C., Huo, L. et al. Mechanical and thermal properties of cationic ring-opening o-cresol formaldehyde epoxy/polyurethane acrylate composites enhanced by reducing graphene oxide. Polym. Bull. 73, 2227–2244 (2016). https://doi.org/10.1007/s00289-016-1605-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-016-1605-7