Abstract

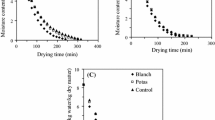

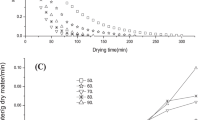

This study aimed at determining the influence of temperature on drying, rehydration and consumed energy characteristics of common wormwood leaves during thin layer drying. The experiments were carried out at temperatures of 50, 60 and 70 °C and a constant air velocity of 0.7 m s−1. The dehydration duration decreased significantly with increasing drying air temperature. The usefulness of five different mathematical models to simulate the experimental drying kinetics was evaluated and the Midilli model was found to be the best model for explaining the curves. Effective moisture diffusivity values were obtained to be in the range of 7.099 × 10−8–3.191 × 10−7 m2 s−1. Rehydration capacity of the dried leaves increased with increasing rehydration water temperature and decreasing drying air temperature. The specific energy consumption decreased with any increment in drying air temperature and varied from 17.64 to 32.09 kWh kg−1.

Similar content being viewed by others

References

Hartley D (1985) Food in England, Futura Publications

Šumic Z, Vakula A, Tepic A, Cakarevic J, Vitas J, Pavlic B (2016) Modeling and optimization of red currants vacuum drying process by response surface methodology (RSM). Food Chem 203:465–475

Aral S, Bese AV (2016) Convective drying of hawthorn fruit (Crataegus spp.): effect of experimental parameters in drying kinetics, color, shrinkage, and rehydration capacity. Food Chem 210:577–584

Onwude DI, Hashin N, Janius RB, Nawi NM, Abdan K (2016) Modeling the thin-layer drying of fruits and vegetables: a review. Compr Rev Food Sci Food Saf 15(3):559–618

Babalis SJ, Belessiotis VG (2004) Influence of drying conditions on the drying constants and moisture diffusivity during the thin- layer drying of figs. J Food Eng 65(3):449–458

Doymaz I (2006) Drying kinetics of black grapes treated with different solutions. J Food Eng 76(2):212–217

Cihan A, Kahveci K, Hacihafizoglu O (2007) Modelling of intermittent drying of thin layer rough rice. J Food Eng 79(1):293–298

Aktas M, Ceylan I, Yilmaz S (2009) Determination of drying characteristics of apples in a heat pump and solar dryer. Desalination 239(1–3):266–275

Doymaz I, Ismail O (2011) Drying characteristics of sweet cherry. Food Bioprod Process 89(1):31–38

Dak M, Pareek NK (2014) Effective moisture diffusivity of pomegranate arils undergoing microwave-vacuum drying. J Food Eng 122:117–121

Sirdhar D, Madhu GM (2015) Drying kinetics and mathematical modelling of Casuarina equisetifolia wood chips at various temperatures. Period Polytech Chem Eng 59(4):288–295

Torki-Harchegani M, Ghasemi-Varnamkhasti M, Ghanbarian D, Sadeghi M, Tohidi M (2016) Dehydration characteristics and mathematical modelling of lemon slices drying undergoing oven treatment. Heat Mass Transf 52(2):281–289

Planinic´ M, Velic´ D, Tomas S, Bilic M, Bucic´ A (2005) Modelling of drying and rehydration of carrots using Peleg’s model. Eur Food Res Technol 221(3):446–451

Ergün K, Çaliskan G, Dirim SN (2016) Determination of the drying and rehydration kinetics of freeze dried kiwi (Actinidia deliciosa) slices. Heat Mass Transf 52(12):2697–2705

Fathima A, Begum K, Rajalakshmi D (2001) Microwave drying of selected greens and their sensory characteristics. Plant Food Hum Nutr 56(4):303–311

Mujaffar S, Loy AL (2016) The rehydration behavior of microwave-dried amaranth (Amaranthus dubius) leaves. Food Sci Nutr. doi:10.1002/fsn3.406

Aghbashlo M, Kianmehr MH, Samimi-Akhijahani H (2008) Influence of drying conditions on the effective moisture diffusivity, energy of activation and energy consumption during the thin-layer drying of berberis fruit (Berberidaceae). Energy Convers Manage 49(10):2865–2871

Martynenko A, Zheng W (2016) Electrohydrodynamic drying of apple slices: energy and quality aspects. J Food Eng 168:215–222

Motevali A, Minaei S, Khoshtaghaza MH (2011) Evaluation of energy consumption in different drying methods. Energy Convers Manage 52(2):1192–1199

Torki-Harchegani M, Ghanbarian D, Ghasemi Pirbalouti A, Sadeghi M (2016) Dehydration behaviour, mathematical modelling, energy efficiency and essential oil yield of peppermint leaves undergoing microwave and hot air treatments. Renew Sust Energy Rev 58:407–418

Beigi M (2016) Influence of drying air parameters on mass transfer characteristics of apple slices. Heat Mass Transf 52(10):2213–2221

Crank J (1975) The mathematics of diffusion, 2nd edn. Oxford University Press, London

Beigi M (2016) Hot air drying of apple slices: dehydration characteristics and quality assessment. Heat Mass Transf 52(8):1435–1442

Balasubramanian S, Sharma R, Gupta RK, Patil RT (2011) Validation of drying models and rehydration characteristics of betel (Piper betel L.) leaves. J Food Sci Technol 48(6):685–691

Kaleemullah S, Kailappan R (2006) Modelling of thin-layer drying kinetics of red chillies. J Food Eng 76(4):531–537

Orikasa T, Koide S, Okamoto S, Imaizumi T, Muramatsu Y, Takeda J, Shiina T, Tagawa A (2014) Impacts of hot air and vacuum drying on the quality attributes of kiwifruit slices. J Food Eng 125:51–58

Doymaz I, Ismail O (2010) Drying and rehydration behaviours of green bell peppers. Food Sci Biotechnol 19(6):1449–1455

Sacilik K, Elicin AK (2006) The thin layer drying characteristics of organic apple slices. J Food Eng 73(3):281–289

Ghanbarian D, Baraani Dastjerdi M, Torki-Harchegani M (2016) Mass transfer characteristics of bisporus mushroom (Agaricus bisporus) slices during convective hot air drying. Heat Mass Transf 52:1081–1088

Tulek Y (2011) Drying kinetics of oyster mushroom (Pleurotus ostreatus) in a convective hot air dryer. J Agric Sci Technol 13(5):655–664

Evin D (2011) Microwave drying and moisture diffusivity of white mulberry: experimental and mathematical modelling. J Mech Sci Technol 25:2711–2718

Minaei S, Motevali A, Ahmadi E, Azizi MH (2012) Mathematical models of drying pomegranate arils in vacuum and microwave dryers. J Agric Sci Technol 14(2):311–325

Erbay Z, Icier F (2010) Thin-layer drying behaviors of olive leaves (Olea europaea L.). J Food Process Eng 33:287–308

Lemus-Mondaca R, Vega-Gálvez A, Moraga NO, Astudillo S (2015) Dehydration of stevia rebaudiana bertoni leaves: kinetics, modeling and energy features. J Food Proces Preserv 39(5):508–520

Seremet L, Botez E, Nistor OV, Andronoiu DG, Mocanu GD (2016) Effect of different drying methods on moisture ratio and rehydration of pumpkin slices. Food Chem 195:104–109

Alibas I (2007) Energy consumption and colour characteristics of nettle leaves during microwave, vacuum and convective drying. Biosyst Eng 96(4):495–502

Beigi M (2016) Energy efficiency and moisture diffusivity of apple slices during convective drying. Food Sci Technol 36(1):145–150

Motevali A, Minaei S, Banakar A, Ghobadian B, Khoshtaghaza MH (2014) Comparison of energy parameters in various dryers. Energy Convers Manage 87:711–725

Tohidi M, Sadeghi M, Torki-Harchegani M (2017) Energy and quality aspects for fixed deep bed drying of paddy. Renew Sust Energy Rev 70:519–528

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Beigi, M. Thin layer drying of wormwood (Artemisia absinthium L.) leaves: dehydration characteristics, rehydration capacity and energy consumption. Heat Mass Transfer 53, 2711–2718 (2017). https://doi.org/10.1007/s00231-017-2018-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-017-2018-3