Abstract

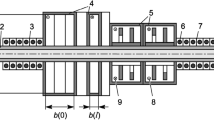

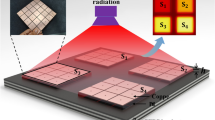

Microwave technology has been employed to heat sheet rubber, the optical fiber temperature online monitor and optical fiber temperature sensor have been employed to measure the temperature in sheet rubber. The temperature of sheet rubber increased with increase of heating time during microwave heating process in which the maximum of temperature was <100 °C and microwave vulcanization process in which the maximum of temperature was <150 °C, the curves of temperature–time presented nonlinearity. The rate of temperature rising in central zone of sheet rubber was higher than the rate of temperature rising in marginal zone of sheet rubber, and the final temperature in central zone of sheet rubber was also higher than the final temperature in marginal zone of sheet rubber. In the microwave heating and vulcanization process of sheet rubber, the maximum of rate of temperature rising and the maximum of temperature belong to the central zone of sheet rubber, so the distribution of electric field was uneven in heating chamber, which led to the uneven temperature distribution of sheet rubber. The higher electric field intensity value converges on the central zone of sheet rubber.

Similar content being viewed by others

References

Sombatsompop N, Kumnuantip C (2006) Comparison of physical and mechanical properties of NR/carbon black/reclaimed rubber blends vulcanized by conventional thermal and microwave irradiation methods. J Appl Polym Sci 100:5039–5048

de Vergara UL, Sarrionandiab M, Gondra K, Aurrekoetxea J (2014) Polymerization and curing kinetics of furan resins under conventional and microwave heating. Thermochim Acta 581:92–99

Li N, Li Y, Hang X, Gao J (2014) Analysis and optimization of temperature distribution in carbon fiber reinforced composite materials during microwave curing process. J Mater Process Technol 214:544–550

Ghosh A, Naskar AK, Khastgir D, De SK (2001) Dielectric properties of blends of silicone rubber and tetraflouroethylene/propylene/vinylidene fluoride terpolymer. Polym Commun 42:9849–9853

Hong YD, Lin BQ, Li H, Dai HM, Zhu CJ, Yao H (2016) Three-dimensional simulation of microwave heating coal sample with varying parameters. Appl Therm Eng 93:1145–1154

Makul N, Rattanadecho P (2010) Microwave pre-curing of natural rubber-compounding using a rectangular wave guide. Int Commun Heat Mass Transfer 37:914–923

Geedipalli SSR, Rakesh V, Datta AK (2007) Modeling the heating uniformity contributed by a rotating turntable in microwave ovens. J Food Eng 82:359–368

Martin D, Ighigeanu D, Mateescu E et al (2002) Vulcanization of rubber mixtures by simultaneous electron beam and microwave irradiation. Radiat Phys Chem 65:63–65

Namitha LK, Sebastian MT (2013) Microwave dielectric properties of flexible silicone rubber—Ba(Zn1/3Ta2/3)O3 composite substrates. Mater Res Bull 48:4911–4916

Trihotri M, Dwivedi UK, Khan FH, Malik MM, Qureshi MS (2015) Effect of curing on activation energy and dielectric properties of carbon black–epoxy composites at different temperatures. J Non-cryst Solids 421:1–13

Vaz RH, Pereira JM, Ervilha AR (2014) Simulation and uncertainty quantification in high temperature microwave heating. Appl Therm Eng 70:1025–1039

Kwak M, Robinson P, Bismarck A, Wise R (2015) Microwave curing of carbon–epoxy composites: penetration depth and material characterization. Compos A 75:18–27

Mishra RR, Sharma AK (2016) Microwave–material interaction phenomena: heating mechanisms, challenges and opportunities in material processing. Compos A 81:78–97

Giri R, Naskar K, Nando GB (2012) Effect of electron beam irradiation on dynamic mechanical, thermal and morphological properties of LLDPE and PDMS rubber blends. Radiat Phys Chem 81:1930–1942

Luan D, Tang J, Pedrow PD et al (2015) Performance of mobile metallic temperature sensors in high power microwave heating systems. J Food Eng 149:114–122

Julrat S, Chongcheawchamnan M, Robertson ID (2014) Characterisation of the dielectric properties of rubber latex from 0.5 to 33 GHz. Biosyst Eng 125:1–8

Li N, Li Y, Zhou J, He Y, Hao X (2015) Drilling delamination and thermal damage of carbon nanotube/carbon fiber reinforced epoxy composites processed by microwave curing. Int J Mach Tools Manuf 97:11–17

Acknowledgments

This project is supported by Natural Science Foundation of Shandong Province in China (Grant No. ZR2013EEL009), and jointly supported by the Project of Shandong Province Science and Technology Development Planning (Grant No. 2012GSF11604). The authors sincerely appreciate the support by Collaborative Innovation Center of Green Tyres & Rubber in Qingdao University of Science & Technology (Grant No. 2014GTR0014).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, HL., Li, T., Liang, Y. et al. Experimental study of temperature distribution in rubber material during microwave heating and vulcanization process. Heat Mass Transfer 53, 1051–1060 (2017). https://doi.org/10.1007/s00231-016-1877-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-016-1877-3