Abstract

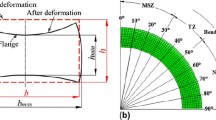

Cross-sectional deformation of the double-ridged rectangular tube inevitably occurs in the rotary draw bending process. It has serious effect on the characteristic of microwave transmission and restricts the quality and performance of tube. Different mandrels play different roles in the bending process, so the rigid and polyvinyl chloride (PVC) mandrels are applied in the E-typed and H-typed rotary draw bending of double-ridged rectangular tube to study their influence on the cross-sectional deformation. Based on the platform of ABAQUS/Explicit, the three-dimensional finite element models for E-typed and H-typed rotary draw bending of H96 brass double-ridged rectangular tube with rigid and PVC mandrels have been established and validated by experiment. Results show that whether in the E-typed or H-typed bending, the PVC mandrel has better inhibitory effect on the cross-sectional long-side deformation δ L, short-side deformation δ W, and spacing deformation between the bottom of ridge grooves δ w of the tube. And the PVC mandrel can be more helpful to reduce the width deformation of ridge grooves of the tube in H-typed bending. The rigid mandrel can restrain the width expansion deformation of outer ridge groove of the tube more effectively in E-typed bending. However, whether using the rigid or PVC mandrel, the width shrinkage deformation of inner ridge groove of the tube in E-typed bending is less affected by the type of mandrels. And the width of two ridge grooves on sidewalls of the tube in H-typed bending also has the obvious shrinkage deformation.

Similar content being viewed by others

References

Lu M, Leonard PJ (2004) Design of trapezoidal-ridge waveguide by finite-element method. IEE Proc Microw Antennas Propag 151(3):205–211

Wang T, Chen XQ (2009) Study of characteristic impedance of double ridge waveguide using the finite element method. Electronics Quality 9:4–5,17 (In Chinese)

Yang H, Zhan M, Liu YL (2004) Some advanced plastic processing technologies and their numerical simulation. J. Mater. Process. Tech. 151:63–69

Wang YS (1994) The double ridge waveguide process. Electronics process technology 6:18–19 (In Chinese)

Ruan ZG (2000) The bending and twisting process of the 24JS-3500 double ridge waveguide tube. Technology and Economy Information of Shipbuilding Industry 7:41–44 (In Chinese)

Xiao YH, Liu YL, Yang H (2014) Research on cross-sectional deformation of double-ridged rectangular tube during H-typed rotary draw bending process. Int. J. Adv. Manuf. Tech. 73:1789–1798

Xiao YH, Liu YL, Yang H, Ren JH (2014) Optimization of processing parameters for double-ridged rectangular tube rotary draw bending based on grey relational analysis. Int. J. Adv. Manuf. Tech. 70(9–12):2003–2011

Xiao YH, Liu YL, Yang H (2014) Prediction of forming limit based on cross-sectional distortion for rotary draw bending of H96 brass double-ridged rectangular tube. Int. J. Adv. Manuf. Tech. 71(5–8):1445–1454

Lee H, Van TCJ, Field D (2005) Finite element bending analysis of oval tubes using rotary draw bender for hydroforming applications. J. Mater. Process. Tech. 168:327–335

Mentella A, Strano M (2012) Rotary draw bending of small diameter copper tubes: predicting the quality of the cross-section. P I Mech Eng B-J Eng 226(2):267–278

Peng YH, Tang D, Li DY (2008) Study on the influence of mandrel type on copper tube rotary draw bending. Int. J. Mater. Prod. Tec. 32(4):406–422

Mohammad S, Mahmoud F, Mahmoud K, Mohsen N (2015) A chain link mandrel for rotary draw bending: experimental and finite element study of operation. Int J Adv Manuf Tech 79:1071–1080

Xue X, Liao J, Vincze G, Gracio JJ (2015) Modelling of mandrel rotary draw bending for accurate twist springback prediction of an asymmetric thin-walled tube. J. Mater. Process. Tech. 216:405–417

Zhu YX, Liu YL, Yang H (2012) Sensitivity of springback and section deformation to process parameters in rotary draw bending of thin-walled rectangular H96 brass tube. T Nonferr Metal Soc 22:2233–2240

Liu KX, Liu YL, Yang H (2015) A study on mandrel role in rotary draw bending of rectangular tube. Int J Mater Prod Tec 50(1):65–79

Alves LM, Pardal TCD, Martins PAF (2009) Forming of thin-walled hollow spheres using sacrificial polymer mandrels. Int J Mach Tool Manu 49:521–529

Alves LM, Martins PAF (2009) Cold expansion and reduction of thin-walled PVC tubes using a die. J. Mater. Process. Tech. 209:4229–4236

Utsumi N, Sakaki S (2002) Countermeasures against undesirable phenomena in the draw-bending process for extruded square tubes. J Mater Process Tech 123:264–269

Nakajima K, Utsumi N, Yoshida M (2013) Suppressing method of the cross section deformation for extruded square tubes in press bending. Int J Precis Eng Man 14(6):965–970

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, C., Liu, Y. & Yang, H. Influence of different mandrels on cross-sectional deformation of the double-ridge rectangular tube in rotary draw bending process. Int J Adv Manuf Technol 91, 1243–1254 (2017). https://doi.org/10.1007/s00170-016-9817-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9817-4