Abstract

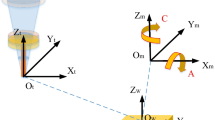

Five-axis machine tools have two additional rotary freedoms compared with the traditional three-axis machine tool, and it is widely adopted for manufacturing parts such as turbine blade. However, five-axis machine tool has more complicated problem than three-axis machine tool, for example, non-linearity machining error. The non-linearity error is always defined as the maximum deviation of cutter location (CL) point from the theory programming plane. But sometimes, the deviation of tool orientation from the theory programming plane has more influence on machining precision, for instance, in five-axis flank milling. In this sense, the purpose of this paper is to avoid the tool orientation out of the theory programming plane by using a new method called SSALI. Firstly, the reason causing non-linearity error in five-axis flank milling is explained by illustrating the tool orientation interpolation between two adjacent CL points. Secondly, a kinematics model of rotation axis is developed to describe the generating process of non-linearity error, and a single spherical angle linear interpolation (SSALI) method is proposed. Then, the optimization algorithm is established to avoid the non-linearity error. Finally, the algorithm is implemented and verified experimentally in a five-axis machine tool. The results show that the maximum error value can be greatly decreased by using the method in this paper.

Similar content being viewed by others

References

Lasemi A, Xue D, Gu P (2010) Recent development in CNC machining of freeform surfaces: a state-of-the-art review. Comput Aided Des 42(7):641–654

Loney GC, Ozsoy TM (1987) NC machining of free-form surfaces. Comput Aided Des 19(2):85–90

Li SX, Jerard RB (1994) 5-axis machining of sculptured surface with a flat-end cutter. Comput Aided Des 26(3):165–178

Yang XJ, Zhou YS, Chen ZZ (2012) Analysis and control of tool path interpolation error in rotary axes motions of five-axis CNC milling. J Mech Eng 48(3):140–146

Bohez ELJ (2002) Five-axis milling machine tool kinematic chain design and analysis. Int J Mach Tool Manu 42(4):505–520

Mann S, Bedi S, Israeli G (2010) Machine models and tool motions for simulating five-axis machining. Comput Aided Des 42:231–237

Liang H, Hong H, Svoboda J (2002) A combined 3D liner and circular interpolation technique for multi-axis CNC machining. J Manuf Sci Eng ASME 124:305–312

Wu DZ, Wang YH, Feng JC (2007) Analysis and control of the non-linear errors in five-axis NC machining. J Shanghai Jiaotong Univ 41(10):1608–1612

Ji JF, Zhou LS, An LL (2010) A new determination method of tool step for 5-axis NC machining. J Chongqing Univ 33(4):37–42

Liang H, Hong H, Svoboda J (2003) A cutter orientation modification method for the reduction of non-linearity errors in five-axis CNC machining. Mach Sci Technol 7:1–18

Remus O, Shafayet H (2011) Comparing the kinematic efficiency of five-axis machine tool configurations through nonlinearity errors. Comput Aided Des 43(9):1163–1172

Makhanov SS, Munlin M (2007) Optimal sequencing of rotation angles for five-axis machining. Int J Adv Manuf Technol 35:41–54

Lu YA, Zhu LM, Bi QZ (2016) Five-axis flank milling of impellers. Optimal geometry of a conical tool considering stiffness and geometric constraints. Proc Inst Mech Eng B J Eng Manuf 230(1):38–52

Kuo CL, Chu CH (2015) Iterative optimization of tool path planning in five-axis flank milling by sampling techniques. 2015 I.E. International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore

Li MY, Liu XL, Jia DK, Liang Q (2015) Interpolation using non-uniform rational B-spline for the smooth milling of ruled-surface impeller blades. Proc Inst Mech Eng B J Eng Manuf 229(7):1118–1130

Zhou YY, Schulze J, Schaffler S et al. (2013) Dual spherical spline and its application in tool path planning for 5-axis flank milling. International Joint Conference, VISIGRAPP 2011, Vilamoura, Portugal

Chu CH, Hsieh HT, Lee CH, Yan CY (2015) Spline-constrained tool-path planning in five-axis flank machining of ruled surfaces. Int J Adv Manuf Technol 80(9):2097–2104

Yu L, Wang YH, Jin YQ (2013) Envelope surface formed by cutting edge under runout error in five-axis flank milling. Int J Adv Manuf Technol 69(1):543–553

Chen KH (2011) Investigation of tool orientation for milling blade of impeller in five-axis machining. Int J Adv Manuf Technol 52(1):235–244

Zheng JM, Lin H, Gai RL (2011) Fast smooth interpolation control strategy of rotary axes for five-axis CNC systems. J Mech Eng 47(9):105–111

Luo M, Wu BL, Li S (2009) Five-axis tool orientation optimization based on kinematical method. J Mech Eng 45(9):158–163

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, K., Zhang, L. & Yan, Y. Single spherical angle linear interpolation for the control of non-linearity errors in five-axis flank milling. Int J Adv Manuf Technol 87, 3289–3299 (2016). https://doi.org/10.1007/s00170-016-8720-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8720-3