Abstract

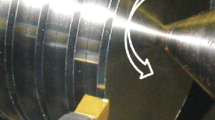

A 2D orthogonal cutting process of Ti6Al4V was simulated to study the dynamic process of serrated chip formation and to establish the relationship between the tool-chip contact length and the saw-tooth pitch. All orthogonal cut experiments were carried out using a machined Ti6Al4V titanium alloy bar with PCBN tools. The features of the chip back surface and the cross-section surface were analyzed. The factors that affect the formation of adiabatic shear band were investigated. For the same chip length, the variation of the number of adiabatic shear band with cutting speed was investigated. The tool-chip contact length and saw-tooth pitch were measured to explore both the variation trends with cutting speed and their internal relations. When the cutting speeds are over 110 m/min, the whole tool-chip contact area can be treated as sticking. The shear stress was used to represent the tool-chip interface characteristics, and the trend of shear stress with cutting speed was studied.

Similar content being viewed by others

References

Ezugwu EO, Wang ZM (1997) Titanium alloys and their machinability—a review. J Mater Process Technol 68:262–274

Arrazola PJ, Garay A, Iriarte LM, Armendia M, Marya S, Maitre FL (2009) Machinability of titanium alloys (Ti6Al4V and Ti555.3). J Mater Process Technol 209:2223–2230

Klamecki BE (1982) Catastrophe theory models of chip formation. J Eng IndTrans ASME 104:369–374

Manyindo BM, Oxley PLB (1986) Modeling the catastrophic shear type of chip when machining of stainless steel. Proc Inst Mech Eng 200:349–358

Vyas A, Shaw MC (1999) Mechanics of saw-tooth chip formation in metal cutting. J Manuf Sci Eng 121:163–172

Davies MA, Chou Y, Evans CJ (1996) On chip morphology, tool wear and cutting mechanics in finish hard turning. CIRP Ann 45(1):77–82

Davies MA, Burns TJ, Evans CJ (1997) On the dynamics of chip formation in machining hard metals. CIRP Ann 46(1):25–30

Cotterell M, Byrne G (2008) Dynamics of chip formation during orthogonal cutting of titanium alloy Ti-6Al-4V. CIRP Ann Manuf Technol 57:93–96

Wang SP (2012) Investigation on shear band microstructure and microhardness of adiabatic of saw-tooth chip in machining TC4 alloy. Chin Mech Eng 23(9):1117–1121

Wang B, Liu ZQ (2014) Investigations on the chip formation mechanism and shear localization sensitivity of high-speed machining Ti6A14V. Int J Adv Manuf Technol 75:1065–1076

Iqbal SA, Mativenga PT, Sheikh MA (2009) A comparative study of the tool-chip contact length in turning of two engineering alloys for a wide range of cutting speeds. Int J Adv Manuf Technol 42:30–40

Yang QB, Liu ZQ, Shi ZY, Wang B (2014) Analytical modeling of adiabatic shear band spacing for serrated chip in high-speed machining. Int J Adv Manuf Technol 71:1901–1908

Gekonde HO, Subramanian SV (2002) Tribology of tool-chip interface and tool wear mechanisms. Surf Coat Technol 149:151–160

Qi HS, Mills B (2003) Modelling of the dynamic tool-chip interface in metal cutting. J Mater Process Technol 138:201–207

Kilic DS, Raman S (2007) Observations of the tool-chip boundary conditions in turning of aluminum alloys. Wear 262:889–904

Bahi S, Nouari M, Moufki A, Mansori ME, Molinari A (2012) Hybrid modelling of sliding-sticking zones at the tool-chip interface under dry machining and tool wear analysis. Wear 286–287:45–54

Sun J, Guo YB (2008) A new multi-view approach to characterize 3D chip morphology and properties in end milling titanium Ti-6Al-4V. Int J Mach Tools Manuf 48(12-13):1486–1494

Chen M, An QL, Liu ZQ (2012) Fundamentals and applications of high speed cutting, 1st edn. Shanghai Scientific and Technical Publishers, Shanghai

Ai X (2003) High speed machining technology, 1st edn. National Defense Industry, Beijing

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, Pn., Qiu, Xy., Tang, Sw. et al. Study on dynamic characteristics of serrated chip formation for orthogonal turning Ti6Al4V. Int J Adv Manuf Technol 86, 3289–3296 (2016). https://doi.org/10.1007/s00170-016-8459-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8459-x