Abstract

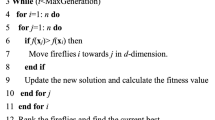

This paper proposes a modified discrete firefly algorithm (MDFA) to solve the problem of assembly sequence planning. Firstly, to improve the performance of the firefly algorithm (FA), we proposed a MDFA by endowing the fireflies with the capability of changeable visual range. The computing case shows the proposed algorithm is more effective and robust than standard FA, genetic algorithm and particle swarm optimization algorithm. Secondly, a method of how to set parameters for FA and MDFA is proposed. This method is practical in the application of FA to solve discrete problem. Thirdly, to make the sequences more closer to real industrial requirements, a so called process precedence relations (PPR) evaluation function is presented, which not only considering the interference between parts, assembly tools and clamps, but also regarding the assembly order between parts and their reference parts. Finally, the evolution performance of the MDFA is investigated, and the performance of the proposed approach to solve ASP is verified through two cases study.

Similar content being viewed by others

References

Shan HB, Li SX, Gong DG, Lou P (2006) Genetic simulated annealing algorithm-based assembly sequence planning. Int Technol Innov Conf 2006 (ITIC 2006)CP 524:1573– 1579

Pan C (2005) Integrating CAD files and automatic assembly sequence planning, Ph.D. thesis. Iowa State University

Lee S, Shin YG (1990) Assembly planning based on geometric reasoning. Comput Graph 14(2):237–250

Wilson RH (1998) Geometric reasoning about assembly tools. Artif Intell 98(1):237–279

Chung C, Peng Q (2006) A novel approach to the geometric feasibility analysis for fast assembly tool reasoning. Int J Adv Manuf Technol 31(1):125–134

Su Q (2007) Computer aided geometric feasible assembly sequence planning and optimizing. Int J Adv Manuf Technol 33(1):48–57

Zha XF, Lim SY, Fok SC (1998) Integrated knowledge-based assembly sequence planning. Int J Adv Manuf Technol 14(1):50–64

Yin Z, Ding H, Li H, Xiong Y (2003) A connector-based hierarchical approach to assembly sequence planning for mechanical assemblies. Comput-Aided Des 35(1):37–56

Hsu YY, Tai PH, Wang MW, Chen WC (2011) A knowledge-based engineering system for assembly sequence planning. Int J Adv Manuf Technol 55(5):763–782

Dong T, Tong R, Zhang L, Dong J (2007) A knowledge-based approach to assembly sequence planning. Int J Adv Manuf Technol 32(11):1232–1244

Wu M, Prabhu V, Li X (2011) Knowledge-based approach to assembly sequence planning. J Algorithm Comput Technol 5(1):57–70

Tseng HE, Li RK (1999) A novel means of generating assembly sequences using the connector concept. J Intell Manuf 10(5):423–435

Li J, Wang Q, Huang P, Shen H (2010) A novel connector-knowledge-based approach for disassembly precedence constraint generation. Int J Adv Manuf Technol 49(1):293–304

Rashid MFF, Hutabarat W, Tiwari A (2012) A review on assembly sequence planning and assembly line balancing optimisation using soft computing approaches. Int J Adv Manuf Technol 59(1):335–349

Jimnez P (2011) Survey on assembly sequencing: a combinatorial and geometrical perspective. J. Intell. Manuf. :1–16

Bautista J, Lusa A, Suarez R, Mateo M, Pastor R, Corominas A (1999) Application of genetic algorithms to assembly sequence planning with limited resources. In: Assembly and Task Planning, 1999. (ISATP’99) Proceedings of the 1999 IEEE International Symposium on. IEEE, pp 411–416

Chen SF, Liu YJ (2001) An adaptive genetic assembly-sequence planner. Int J Comput Integr Manuf 14 (5):489–500

Smith SSF, Liu MYJ (2001) The application of multi-level genetic algorithms in assembly planning. J Indus Technol 17 (4)

Chen RS, Lu KY, Yu SC (2002) A hybrid genetic algorithm approach on multi-objective of assembly planning problem. Eng Appl Artif Intell 15(5):447–457

Zhou W, Zheng JR, Yan JJ, Wang JF (2011) A novel hybrid algorithm for assembly sequence planning combining bacterial chemotaxis with genetic algorithm. Int J Adv Manuf Technol 52(5):715–724

Lazzerini B, Marcelloni F (2000) A genetic algorithm for generating optimal assembly plans. Artif Intell Eng 14(4):319–329

Che ZH (2010) A genetic algorithm-based model for solving multi-period supplier selection problem with assembly sequence. Int J Prod Res 48(15):4355–4377

Tseng HE, Wang WP, Shih HY (2007) Using memetic algorithm with guided local search to solve assembly sequence planning. Expert Syst Appl 33:451–467

Liang G, Weirong Q, Xinyu L, Wang J (2010) Application of memetic algorithm in assembly sequence): planning. Int J Adv Manuf Technol 49:91175–1184

Milner JM, Graves SC, Whitney DE (1994) Using simulated annealing to select least-cost assembly sequences. In: 1994 IEEE International Conference on Robotics and Automation, 1994. Proceedings. IEEE, pp 2058–2063

Cakir B, Altiparmak F, Dengiz B (2010) Multi-objective optimization of a stochastic assembly line balancing: a hybrid simulated annealing algorithm. Comput Indu Eng 60(3):376

Wang JF, Liu JH, Zhong YF (2005) A novel ant colony algorithm for assembly sequence planning. Int J Adv Manuf Technol 25(11-12):1137–1143

Shuang B, Chen J, Li Z (2008) Microrobot based micro-assembly sequence planning with hybrid ant colony algorithm. Int J Adv Manuf Technol 38(11-12):1227–1235

Shan H, Zhou S, Sun Z (2009) Research on assembly sequence planning based on genetic simulated annealing algorithm and ant colony optimization algorithm. Assem Autom 29(3):249–256

Agrawal S, Tiwari MK (2008) A collaborative ant colony algorithm to stochastic mixed-model U-shaped disassembly line balancing and sequencing problem. Int J Prod Res 46(6):1405–1429

McMullen PR, Tarasewich P (2006) Multi-objective assembly line balancing via a modified ant colony optimization technique. Int J Prod Res 44(1):27–42

Lv H, Lu C (2010) An assembly sequence planning approach with a discrete particle swarm optimization algorithm. Int J Adv Manuf Technol 50(5-8):761–770

Anghinolfi D, Paolucci M (2009) A new discrete particle swarm optimization approach for the single-machine total weighted tardiness scheduling problem with sequence-dependent setup times. Eur J Oper Res 193(1):73–85

Wang Y, Liu JH (2010) Chaotic particle swarm optimization for assembly sequence planning. Robot Comput-Integr Manuf 26(2):212–222

Chang CC, Tseng HE, Meng LP (2009) Artificial immune systems for assembly sequence planning exploration. Eng Appl Artif Intell 22(8):1218–1232

Cao PB, Xiao RB (2007) Assembly planning using a novel immune approach. Int J Adv Manuf Technol 31(7–8):770–782

Zhou W, Yan J, Li Y, Xia C, Zheng J (2012) Imperialist competitive algorithm for assembly sequence planning. Int J Adv Manuf Technol:1–10

Yang XS (2009) Firefly algorithms for multimodal optimization. In: Stochastic algorithms: foundations and applications. Springer, Berlin, pp 169–178

Yang XS (2010) Firefly algorithm, stochastic test functions and design optimisation. Int J Bio-Inspired Comput 2(2):78–84

Yang XS (2010) Firefly algorithm, Levy flights and global optimization. In: Research and Development in Intelligent Systems XXVI. Springer, London, pp 209–218

Horng MH (2012) Vector quantization using the firefly algorithm for image compression. Expert Syst Appl 39(1):1078– 1091

Jati GK (2011) Evolutionary discrete firefly algorithm for travelling salesman problem. In: Adaptive and Intelligent Systems. Springer, Berlin, pp 393–403

Wang G, Guo L, Duan H, Liu L, Wang H (2012) A modified firefly algorithm for UCAV path planning. Int J Hybrid Inf Technol 5(3):123–144

Liu C, Gao Z, Zhao W (2012) A new path planning method based on firefly algorithm. In: 2012 Fifth International Joint Conference on Computational Sciences and Optimization (CSO). IEEE, pp 775–778

Coelho LDS (2012) Mariani, VC, Firefly algorithm approach based on chaotic Tinkerbell map applied to multivariable PID controller tuning. Computers & Mathematics with Applications

Chai-ead N, Aungkulanon P, Luangpaiboon P (2011) Bees and firefly algorithms for noisy nonlinear optimisation problems. In: Proceedings of the International Multi Conference of Engineering and Computer Scientists, vol 2

Khadwilard A, Chansombat S, Thepphakorn T, Thapatsuwan P, Chainate W, Pongcharoen P (2011) Application of firefly algorithm and its parameter setting for job shop scheduling. In: First Symposium on Hands-On Research and Development, vol 1

Marichelvam MK, Prabaharan T, Yang XS (2013) A discrete firefly algorithm for the multi-objective hybrid flowshop scheduling problems. IEEE transactions on evolutionary computation, issues 99

Sanaei P, Akbari R, Zeighami V, Shams S (2013) Using firefly algorithm to solve resource constrained project scheduling problem. In: Proceedings of Seventh International Conference on Bio-Inspired Computing: Theories and Applications (BIC-TA 2012). Springer, India, pp 417–428

Hassanzadeh T, Meybodi M. R (2012) A new hybrid approach for data clustering using firefly algorithm and K-means. In: Artificial Intelligence and Signal Processing (AISP), 2012 16th CSI International Symposium on. IEEE, pp 007–011

Zeng B, Li M, Zhang Y, Ma J (2013) Research on assembly sequence planning based on firefly algorithm. Chin J Mech Eng 49(11):177–184. In Chinese

Zeng B, Li M, Zhang Y (2014) Research on assembly sequence planning based on improved firefly algorithm. Comput Integr Manuf Syst 20(4):799–806. In Chinese

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, M., Zhang, Y., Zeng, B. et al. The modified firefly algorithm considering fireflies’ visual range and its application in assembly sequences planning. Int J Adv Manuf Technol 82, 1381–1403 (2016). https://doi.org/10.1007/s00170-015-7457-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7457-8