Abstract

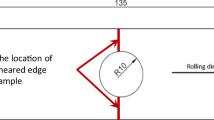

Based on the crack mechanism of hot forming, the causes of cracks occurring during the hot forming of complex structural parts were investigated in this study. High temperature flow stress model of ultrahigh strength steel (UHSS) BR1500HS was established using the true stress–strain curves of BR1500HS in high-temperature tensile. A finite element model (FEM) was built to investigate the causes of defects in hot forming, particularly the necking occurring at the end parts in plan stress status. Then, hot forming process and structure optimizing methods were proposed. According to the results of numerical simulation, it can be concluded that the indirect hot forming process can avoid forming defects and optimize preforming drawing height to 24.5 mm. Through changing the end size of blank to control the metal flow, crack occurring at the end of parts can be solved, since the material in two-way tensile stress state can flow compensation in one direction and therefore reduce the flow resistance. The experimental results are in good agreement with numerical simulation results, which indicates that the proposed method can avoid defects and meet the design requirements.

Similar content being viewed by others

References

Lim WS, Choi HS, Ahn SY, Kim BM (2009) Cooling channel design of hot stamping tools for uniform high-strength components in hot stamping process. Int J Adv Manuf Technol 70(5–8):1189–1203

Liu HS, Lei CX, Xing ZW (2013) Cooling system of hot stamping of quenchable steel BR1500HS: optimization and manufacturing methods. Int J Adv Manuf Technol 69:211–223

Bariani PF, Bruschi S, Ghiotti A, Turetta A (2008) Testing formability in the hot forming of HSS. Annals CIRP 57:265–268

Barcellona A, Palmeri D (2009) Effect of plastic hot deformation on the hardness and continuous cooling transformations of 22MnB5 microalloyed boron steel. Metall Mater Trans A 40:1160–1174

Liu HS, Xing ZW, Lei CX (2012) Hot formation quality of high strength steel BR1500HS for hot stamping without cooling system. Trans Nonferrous Metals Soc China 22:542–547

Min JY, Lin JP, Li JY, Bao WH (2010) Investigation on hot forming limits of high strength steel 22MnB5. Comp Mater Sci 49:326–332. doi:10.1016/j.commatsci.2010.05.018, DOI:10.1016/j.commatsci.2010.05.018#doilink

Bok HH, Choi JW, Barlat F, Suh DW, Lee MG (2015) Thermomechanical–metallurgical modeling for hot-press forming in consideration of the prior austenite deformation effect. Int J Plast 58:154–183

Liu HS, Fu MW (2014) Prediction and analysis of ductile fracture in sheet metal forming—part II: application of the modified Ayada criterion. Int J Damage Mech. doi:10.1177/1056789514535231

Mori K, Abe Y, Kidoma Y, Kadarno P (2013) Slight clearance blanking of ultra-high strength steel sheets using punch having small round edge. Int J Mach Tools Manuf 65:41–46

Chung K, Ma N, Park T, Kim D, Yoo D, Kim C (2011) A modified damage model for advanced high strength steel sheets. Int J Plast 27:1485–1511

Yu S, Xie XL, Zhang J, Zhao J (2007) Ductile fracture modeling of initiation and propagation in sheet-metal blanking processes. J Mater Process Technol 187–188:169–172

Mori K, Saito S, Maki S (2008) Warm and hot punching of ultra high strength steel sheet. Annals CIRP 57:321–324

Merklein M, Lechler J (2008) Determination of material and process characteristics for hot stamping process of quenchable ultra high strength steels with respect to a FE-based process design. SAE International, SAE Technical Paper Series

Cora ÖN, Koc M (2009) Experimental investigation on wear resistance characteristics of alternative die materials for stamping of advanced high-strength steels (AHSS). Int J Mach Tools Manuf 49:897–905

Åkerström P, Bergman G, Oldenburg M (2007) Numerical implementation of a constitutive model for simulation of hot forming. Model Simul Mater Sci Eng 15:105–109

Naderi M, Durrenberger L, Molinari A, Bleck W (2008) Constitutive Relationships for 22MnB5 boron steel deformed isothermally at high temperatures. Mater Sci Eng A 478:130–139

Åkerström P, Oldenburg M (2006) Austenite decomposition during press hardening of a boron steel-computational simulation and test. J Mater Process Technol 174:399–406

Neto DM, Oliveira MC, Menezes LF, Alves JL (2013) Nagata patch interpolation using surface normal vectors evaluated from the IGES file. Finite Elem Anal Des 72:35–46

Neto DM, Oliveira MC, Menezes LF, Alves JL (2014) Comparing faceted and smoothed tool surface descriptions in sheet metal forming simulation. Int J Mater Form. doi:10.1007/s12289-014-1177-8

Merklein M, Lechler J (2008) Determination of material and process characteristics for hot stamping process of quenchable ultra highstrength steels with respect to a FE-based process design. SAEInternational, SAE Technical Paper Series

Lorenz D, Naderi M, Ketabchi M, Abbasi M, Bleck W (2011) Analysis of microstructure and mechanical properties of different high strength carbon steels afterhotforming. J Mater Process Technol 211:1117–1125

Xing ZW, Bao J, Yang YY (2009) Numerical simulation of hot forming of quenchable boron steel. Mater Sci Eng A 499:28–31

Karbasian H, Tekkaya AE (2010) A review on hot forming. J Mater Process Technol 210:2103–2118

Liu HS, Yang YY, Yu ZZ (2009) The application of a ductile fracture criterion to the prediction of the forming limit of sheet metals. J Mater Process Technol 29:5443–5447

Menezes PL, Lovell MR, Avdeev IV, Lin JS, Higgs CF (2014) Studies on the formation of discontinuous chips during rock cutting using an explicit finite element model. Int J Adv Manuf 70:635–648

Slima KB, Penazzi L, Mabru C, Ronde-Oustau F (2013) Fatigue analysis-based numerical design of stamping tools made of cast iron. Int J Adv Manuf 67:1643–1650

Li H, Chen J, Yang J (2013) Experiment and numerical simulation on delamination during the laminated steel sheet forming processes. Int J Adv Manuf 68:641–649

Zhu B, Zhang YS, Li J, Wang H, Ye ZC (2011) Simulation research of hot forming and phase transition of automotive high strength steel. J Mater Res Innov 15:426–430

Naderi M, Ketabchi M, Abbasi M, Bleck W (2011) Analysis of microstructure and mechanical properties of different high strength carbon steels after hot forming. J Mater Process Technol 211:1117–1125

Naderi M, Saeed-Akbari A, Bleck W (2008) The effects of non-isothermal deformation on martensitic transformation in 22MnB5 steel. Mater Sci Eng A 478:445–455

Kim HY, Park JK, Lee MG (2014) Phase transformation-based finite element modeling to predict strength and deformation of presshardened tubular automotive part. Int J Adv Manuf 70:1787–180

Li FF, Fu MW, Lin JP, Wang XN (2014) Experimental and theoretical study on the hot forming limit of 22MnB5 steel. Int J Adv Manuf 71:297–306

Liu HS, Liu W, Bao J (2011) Numerical and experimental investigation into hot forming of ultra high strength steel sheet. J Mater Eng Perform 20:1–10

Molinari A, Ravichandran G (2005) Constitutive modeling of the high-strain-rate deformation in metals based on the evolution of an effective microstructural length. J Mech Mater 37:737–752

Zhu WF, Zhou JQ (2010) Optimal method for auto-body closure panel fitting using Hausdorff distance criteria. Int J Adv Manuf Technol 48:1019–1029

So H, Faßmann D, Hoffmann H, Golle R, Schaper M (2012) An investigation of the blanking process of the quenchable boron alloyed steel 22MnB5 before and after hot stamping process. J Mater Process Technol 212:437–449

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shang, X., Zhou, J., Zhuo, F. et al. Analysis of crack for complex structural parts and simulation optimization during hot forming. Int J Adv Manuf Technol 80, 373–382 (2015). https://doi.org/10.1007/s00170-015-6990-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-6990-9