Abstract

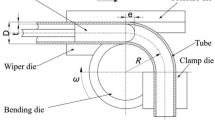

According to the working way of the numerically controlled (NC) tube bender and taking the additional tensile force into account, the formulas are derived to calculate the average principal stress in different directions of the bending tube surface, the equivalent stress, the variation of wall thickness, and the ratio of the minor axis to the original radius of outer contour and validated by the experiments. The corresponding experiments and simulation analysis are performed to compare with the calculated results, and it is revealed that the equivalent stress of the bending tube surface is non-uniform and the maximum equivalent stress is localized in smaller deformation field around the bending terminating end. The consideration of the additional tensile force makes the equivalent stress in the outer convex portion of tube remarkably greater than that in the inner concave portion of tube, accelerating the thinning of the tube’s wall and the ovalization of tube’s outer contour. The approximate calculation formulae of additional tensile force is also derived and based on the deformation analysis; the proper adjustment of the additional tensile force could improve the quality of the NC bending tube.

Similar content being viewed by others

References

Guan YJ, Yuan GP, Sun S, Zhao GQ (2012) Process simulation and optimization of laser tube bending. Int J Adv Manuf Technol 65:333–342

Huang YM, Huang YM (2002) Influence of punch radius and angle on the outward curling process of tubes. Int J Adv Manuf Technol 19:587–596

Liu KX, Liu YL, Yang H (2013) Experimental study on the effect of dies on wall thickness distribution in NC bending of thin-walled rectangular 3A21 aluminum alloy tube. Int J Adv Manuf Technol 68:1867–1874

Kim YJ, Kim JH (2008) Effects of local wall thinning on plastic limit loads of elbows using geometrically linear FE limit analyses. Eng Fract Mech 75:2225–2245

Murata M, Kuboki T, Takahashi K, Goodarzi M, Jin Y (2008) Effect of hardening exponent on tube bending. J Mater Process Technol 201:189–192

Zhao GY, Liu YL, Yang H (2010) Effect of clearance on wrinkling of thin-walled rectangular tube in rotary draw bending process. Int J Adv Manuf Technol 50:85–92

Liu YC, Michael LD (2008) Bending collapse of thin-walled circular tubes and computational application. Thin-Walled Struct 46:442–450

Oliveira A, Worswick MJ (2009) Tube bending and hydroforming of aluminium alloy S-rails. Int J Mater Form 2:197–215

Strano M (2005) Automatic tooling design for rotary draw bending of tubes. Int J Adv Manuf Technol 26:733–740

Li H, Yang H (2009) Numerical study on deformation behaviors of thin-walled tube NC bending with large diameter and small bending radius. Comput Mater Sci 45:921–934

Zhan M, Huang T, Jiang ZQ, Zhang PP, Yang H (2013) Determination of process parameters for the NC bending of a TA18 tube. Int J Adv Manuf Technol 68:663–672

Zhang ZY, Yang H, Li H, Ren N, Tian YL (2011) Bending behaviors of large diameter thin-walled CP-Ti tube in rotary draw bending. Mater Int 21:401–412

Da-xin E, He HH, Liu XY (2009) Experimental study and finite element analysis of spring-back deformation in tube bending. Int J Mineral Metall Mater 2:177–183

Daxin E, Liu YF (2008) Springback and time-dependent springback of 1Cr18Ni9Ti stainless steel tubes under bending. Mater Des 31:1256–1261

Daxin E, Chen MF (2010) Numerical solution of thin-walled tube beding spingback with exponential hardening law. Steel Res Int 81:286–291

Daxin E, Liu YF, Feng HB (2010) Deformation analysis for the rotary draw bending process of circular tubes: stress distribution and wall thinning. Steel Res Int 81:1084–1088

Liu YF, Daxin E (2011) Effects of cross-sectional ovalization on springback and strain distribution of circular tubes under bending. J Mater Eng Perform 20:1591–1599

Daxin E, Guan ZP, Chen JS (2012) Influence of additional tensile force on springback of tube under rotary draw bending. J Mater Eng Perform 21:2316–2322

Daxin E, Chen JS, Ding J (2012) In-plane strain solution of stress and defects of tube bending with exponential hardening law. Mech Based Des Struct Mach 40:257–276

Daxin E, Chen JS, Yang C (2013) Plane strain solution and cross-section flattening analysis in tube bending with linear hardening law. J Strain Anal 48:198–211

Daxin E, Chen JS, Zhang JW (2013) Effects of process parameters on wrinkling of thin-walled circular tube under rotary draw bending. Int J Adv Manuf Technol 68:1505–1516

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

E., D., Li, R. Influence of additional tensile force on the stress and deformation of numerically controlled tube bending. Int J Adv Manuf Technol 78, 895–905 (2015). https://doi.org/10.1007/s00170-014-6675-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6675-9