Abstract

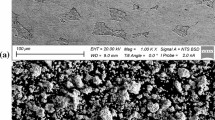

Grinding, being a high specific energy involving process, essentially requires a high-performance cutting fluid when small quantity lubrication (SQL) is employed. In SQL, a small volume of metal working fluid is broken into micro-droplets by a compressed air jet so that the aerosol jet cools and lubricates machining zone more efficiently than flood cooling. In the present work, a new generation grinding fluid was indigenously synthesized by dispersing multi-walled carbon nanotube (MWCNT) in deionized water for SQL grinding of steel by an alumina wheel, and its capability was evaluated in depth in comparison with the commercially used soluble oil. It was observed that a maximum of 1 vol% MWCNT could be dispersed without any settling tendency over 48 h, which subsequently rendered the highest thermal conductivity to the nanofluid sample. It was approximately 35 % higher than that of soluble oil. In a simulative ball (Al2O3) on disc (hardened AISI 52100 steel) test, it was further found that this nanofluid sample was 30 % more lubricious than its counterpart. The higher heat dissipation ability and better lubricity finally resulted in remarkably superior performance of MWCNT nanofluid to that of soluble oil. In comparison with the later MWCNT nanofluid, in particular, at 3 bar of atomizing air pressure and 350 ml/h flow rate, could offer substantially better G ratio, significantly reduce tangential grinding force and produce comparable surface finish. Additionally, presence of more number of long and sheared chips and less spherical chips in the collected sample was a clear indicator of reduction in grinding temperature when soluble oil was replaced by MWCNT in SQL mode.

Similar content being viewed by others

References

Malkin S, Guo C (2007) Thermal analysis of grinding. CIRP Ann-Manuf Tech 56(2):760–782

Rowe WB (2009) Principles of modern grinding technology. William Andrew publishing, Norwich

Brinksmeier E, Heinzel C, Wittmann M (1999) Friction, cooling and lubrication in grinding. CIRP Ann-Manuf Tech 48(2):581–598

Kalita P, Malshe AP, Arun Kumar S, Yoganath VG, Gurumurthy T (2012) Study of specific energy and friction coefficient in minimum quantity lubrication grinding using oil-based nanolubricants. J Manuf Process 14(2):160–166

Klocke F, Eisenblätter G (1997) Dry cutting. CIRP Ann-Manuf Tech 46(2):519–526

Nguyen TK, Do I, Kwon P (2012) A tribological study of vegetable oil enhanced by nano-platelets and implication in MQL machining. Int J Precis Eng Manuf 13(7):1077–1083

Tasdelen B, Wikblom T, Ekered S (2008) Studies on minimum quantity lubrication (MQL) and air cooling at drilling. J Mat Pro Tech 200(1–3):339–346

Mao C, Tang X, Zou H, Zhou ZX, Yin W (2012) Experimental investigation of surface quality for minimum quantity oil–water lubrication grinding. Int J Adv Manuf Tech 59(1–4):93–100

Tawakoli T, Hadad MJ, Sadeghi MH (2010) Influence on oil-mist parameters on minimum quantity lubrication-MQL grinding process. Int J Mach Tools Manuf 50(6):521–531

Autret R, Liang SY (2003) Minimum quantity lubrication in finish hard turning. HNICEM, 2003

Liao YS, Lin HM (2007) Mechanism of minimum quantity lubrication in high-speed milling of hardened steel. Int J Mach Tools Manuf 47(11):1660–1666

Sadeghi MH, Hadad MJ, Tawakoli T, Vesali A, Emami M (2010) An investigation on surface grinding of AISI 4140 hardened steel using minimum quantity lubrication-MQL technique. Int J Mater Form 3(4):241–251

Shen B, Tung SC, Shih AJ (2008) Application of nanofluids in minimum quantity lubrication grinding. Tribol Trans 51(6):730–737

Ghosh A, Roy S (2013) High speed turning of AISI 4140 steel using twin jet SQL system. MSEC-2013, Jun10-15, University of Wisconsin

Patel HE, Sundararajan T, Das SK (2010) An experimental investigation in to the thermal conductivity enhancement in oxide and metallic nanofluids. J Nanoparticle Res 12:1015–1031

Hwang Y, Park HS, Lee JK, Jung WH (2006) Thermal conductivity and lubrication characteristics of nanofluids. Curr Appl Phy 6(1):67–71

Shen B, Malshe AP, Kalita P, Shih AJ (2008) Performance and behavior of novel MoS2 nanoparticles based grinding fluids in minimum quantity lubrication grinding. Trans NAMRI/SME 36:357–364

Alberts M, Kalaitzidou K, Melkote S (2009) An investigation of graphite nanoplatelets as lubricant in grinding. Int J Mach Tools Manuf 49(12–13):966–970

Kalita P, Malshe AP, Rajurkar KP (2012) Study of tribo-chemical lubricant film formation during application of nanolubricants in minimum quantity lubrication (MQL) grinding. CIRP Ann-Manuf Tech 61(1):327–330

Mao C, Tang X, Zou H, Huang X, Zhou Z (2012) Investigation of grinding characteristic using nanofluid minimum quantity lubrication. Int J Prec Eng Manuf 13(10):1745–1752

Mao C, Zou H, Huang X, Zhang J, Zhou Z (2012) The influence of spraying parameters on grinding performance for nanofluid minimum quantity lubrication. Int J Adv Manuf Tech 64(9–12):1791–1799

Sridharan U, Malkin S (2009) Effect of minimum quantity lubrication (MQL) with nanofluid on grinding behaviour and thermal distortion. Trans of NAMRI/SME 37:629–636

Choi SUS, Zhang ZG, Yu W, Lockwood FE, Grulke EA (2001) Anomalous thermal conductivity enhancement in nanotube suspensions. App Phy Lett 79(14):2252–2254

Cheng L (2009) Nanofluid heat transfer technologies. Recent Patents Eng 3:1–7

Karlsson HL, Cronholm P, Gustafsson J, Moller L (2008) Copper oxide nanoparticles are highly toxic: a comparison between metal oxide nanoparticles and carbon nanotubes. Chem Res Toxicol 21(9):1726–1732

Wu YY, Tsui WC, Liu TC (2007) Experimental analysis of tribological properties of lubricating oil with nanoparticle additives. Wear 262(7–8):819–825

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

ManojKumar, K., Ghosh, A. Synthesis of MWCNT nanofluid and evaluation of its potential besides soluble oil as micro cooling-lubrication medium in SQL grinding. Int J Adv Manuf Technol 77, 1955–1964 (2015). https://doi.org/10.1007/s00170-014-6587-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6587-8