Abstract

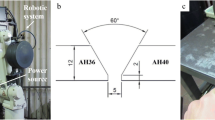

Extensive industrial use of thick high-strength steel plates in Arctic shipbuilding calls for submerged arc welding (SAW) processes with higher deposition rates. One of the most effective ways of increasing the deposition rate is to increase the number of welding wires. Although SAW processes with up to six wires exist, their use is not widespread and two- or three-wire modifications, which are the focus of this paper, are the most common approaches. This paper presents a case study of the development of a welding procedure for welding of high-strength steel shipbuilding plates using a three-wire SAW process. Welding parameters and conditions were evaluated with the aim of achieving a high-quality weld. Optimal parameters for 12-mm plate thickness were found to be: Св-08ГСМТ wire (similar to Mn4Ni1Mo) of 3.2 mm in diameter, single-pass welding, welding flux 48AF-56, I = 840 A, U = 37 V, Q = 5.4 kJ/mm. Optimal parameters were also found for 16-mm plate for two pass welding. Testing of the weld joint included a static tensile strength test, an impact energy test at different temperatures, a bending test, a low-cycle fatigue strength test, microstructure examination and a hardness test. The tests showed satisfactory results that indicate that the developed welding technique is applicable for Arctic shipbuilding applications. The paper provides improved understanding of the welding technique selection process for Arctic shipbuilding as well as providing industrially valuable information about the developed welding technique.

Similar content being viewed by others

References

Sokolov VF (1995) Basics of shipbuilding engineering. Sudostroenie, Saint Petersburg, p 402 (In Russian)

Boekholt R (1996) Welding mechanization and automation in shipbuilding worldwide. Abington Publishing, Cambridge, p 244

Rao PN (2009) Manufacturing technology, Volume 1 of Manufacturing technology: foundry, forming and welding. Tata McGraw-Hill Education, p 502

Moran S (2011) Advances in SAW attack structural welding challenges. Thefabricator.com. http://www.thefabricator.com/article/arcwelding/subarc-for-structurals, May 2011. Accesses 20 May 2014

Gowri S, Hariharah P, Suresh Babu A (2007) Manufacturing technology-I. Pearson Education India, p 464

Group ESAB (2008) ESAB technical handbook: submerged arc welding. ESAB AB, Gothenburg, p 96

Moon H, Beattie R (2002) Development of adaptive fill control for multitorch multipass submerged arc welding. Int J Adv Manuf Technol 19:867–872

Ohkita S, Oikawa H (2007) Latest advances and future prospects of welding technologies. Nippon Steel Technical Report No. 95, p 2–10

ESAB Group (2013) ESAB global products: welding and cutting. OK Autrod 12.51

Gorynin I, Malyshevskii V, Legostaev Y, Grishenko L (1999) High strength weldable steels. Vopr Materialoved 3(20):21–29 (In Russian)

Kobelco (2013) Submerged arc welding consumables, US-80LT

Oerlikon (2013) Handbook consumables, G3Ni2

Oerlikon (2013) Handbook consumables, Mn4Ni1Mo

Prometey (2008) TY 5929-025-07516250-2008. Welding flux grade 48AF-56. Pilot batch. Technical conditions. (In Russian)

“GOST 6996-66. Welded joints. Testing methods for determination of mechanical properties.”

“GOST 14782-86. Nondestructive testing. Welded joints. Ultrasonic methods.”

“GOST 7512-82. Nonde-structive testing. Welded joints. Radiography method.”

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Layus, P., Kah, P., Martikainen, J. et al. Multi-wire SAW of 640 MPa Arctic shipbuilding steel plates. Int J Adv Manuf Technol 75, 771–782 (2014). https://doi.org/10.1007/s00170-014-6147-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6147-2