Abstract

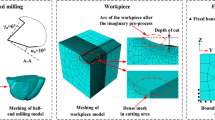

Mill turning is a process applied in the milling of a curved surface while the workpiece rotates around its center. Depending on the eccentricity of the tool, when a flat-end mill tool performs a curved trajectory perpendicular to the rotation axis of the tool, its bottom part is engaged in removing material. In order to optimize the process, the cutting force needs to be predicted. Hence, in this work, an approach to simulating the cutting force in mill turning is presented. The case of non-eccentricity of the tool is considered. The undeformed chip geometry is modeling as a function of the tool engagement considering the process kinematics. Experiments were conducted on a five-axis machining center enabling the measurement of the X–Y and Z components of the cutting forces. In order to verify the influence of the bottom part of the tool on the cutting forces, experiments were carried out using three different cutting depths. Numerical cutting simulations and experimental test results are compared to validate the proposed approach.

Similar content being viewed by others

References

Milling Technical Guide, Sandvik Coromant, http://www.coromant.sandvik.com. Accessed November 2010

Dietzel R (2001) HSC-Tangentialdrehfräsen erzeugt hohe Oberflächenüte. Maschinenmarkt 6:24–26

Savas V, Ozay C (2007) Analysis of the surface roughness of tangential turn-milling for machining with end milling cutter. J Mater Process Technol 186:279–283

Schulz G, Spur G (1990) High speed turn-milling—a new precision manufacturing technology for the machining of rotationally symmetrical workpieces. CIRP Ann Manuf Technol 39(1):107–109

Kopač J, Pogačnik M (1997) Theory and practice of achieving quality surface in turn milling. Int J Mach Tools Manuf 37:709–715

Lisboa ES (1996) Fresotorneamento em Aços Endurecidos (Mill-turning of hard steels), Ms Thesis (in Portuguese), Faculdade de Engenharia Mecânica, Universidade Estadual de Campinas, Campinas, Brazil.

Choudhury SK, Mangrulkar KS (2000) Investigation of orthogonal turn-milling for the machining of rotationally symmetrical work pieces. J Mater Process Technol 99:120–128

Pogačnik M, Kopač J (2000) Dynamic stabilization of the turn-milling process by parameter optimization. Proc Inst Mech Eng B-J Mech Eng Manuf 214:127–135

Neagu C, Gheorghe M, Dumitrescu A (2005) Fundamentals on face milling processing of straight shafts. J Mater Process Technol 166:337–344

Martellotti ME (1941) An analysis of the milling process. Trans ASME 63:667–700

Altintas Y (2000) Manufacturing automation—metal cutting mechanics, machine tool vibrations, and CNC. Cambridge University Press, Cambridge

Araújo AC, Silveira JL (1999) Models for prediction of instantaneous cutting forces in end milling. In: Proceedings of the 15th Brazilian Congress of Mechanical Engineering. November 22–26, São Paulo, Brazil.

Tlusty G (2000) Manufacturing process and equipment. Prentice Hall, Upper Saddle River NJ, USA

Denkena B, Tönshoff H-K (2003) Spanen: Grundlagen, 2nd edn. VDI, Berlin

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Martins Crichigno Filho, J. Prediction of cutting forces in mill turning through process simulation using a five-axis machining center. Int J Adv Manuf Technol 58, 71–80 (2012). https://doi.org/10.1007/s00170-011-3391-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-011-3391-6