Abstract

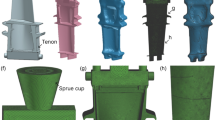

Rapid casting (RC) of freeform-surface parts can be realized via replacing wax patterns by stereolithography (SL) patterns to overcome the disadvantage of time-and-cost consuming in traditional investment casting. It has a promising application prospect in single and small batch production. But ceramic shell cracking during the pyrolyzing of SL patterns limits the application and popularization of RC. In this paper, a simplified thermo-mechanical model was first built and the distribution rule of circumferential stress on the contact boundary between SL patterns and ceramic shell was theoretically derived using displacement method to predict dangerous area of freeform-surface parts. Subsequently, the variation rule of circumferential stress at the predicted dangerous area with changing temperature was revealed by applying transient thermo-mechanical finite element analysis (FEA) on a turbine blade cross section. The comparison of theoretical and FEA results indicated that the circumferential stress was enlarged by the freeform shape of turbine blade instead of being relieved due to the softening of resin. Dangerous temperature range was then determined, so polyimide was added to increase strength under corresponding temperature to prevent shell cracking. An experimental validation was offered to verify our point.

Similar content being viewed by others

References

Tay BY, Evans JRG, Edirisinghe MJ (2003) Solid freeform fabrication of ceramics. Int Mater Rev 48(6):341–370

Choi H, Yang Y, Li XC (2005) Experimental study on integration of laser-based additive/subtractive processes for meso/micro solid freeform fabrication. Int J Adv Manuf Technol 26(4):335–341

Lee CW, Chua CK, Cheah CM, Tan LH, Feng C (2004) Rapid investment casting: direct and indirect approaches via fused deposition modeling. Int J Adv Manuf Technol 23(1):93–101

Chua CK, Feng C, Lee CW, Ang GQ (2005) Rapid investment casting: direct and indirect approaches via model maker II. Int J Adv Manuf Technol 25(1):26–32

Hinczewski C, Corbel S, Chartier T (1998) Stereolithography for the fabrication of ceramic three-dimensional parts. Rapid Prototyping J 4(3):104–111

Cheah CM, Chua CK, Lee CW, Feng C, Totong K (2005) Rapid prototyping and tooling techniques: a review of applications for rapid investment casting. Int J Adv Manuf Technol 25(3):308–320

Raja V, Zhang SJ, Garside J, Ryall C, Wimpenny D (2006) Rapid and cost-effective manufacturing of high-integrity aerospace components. Int J Adv Manuf Technol 27(7):759–777

Yao WL, Leu MC (1999) Analysis of shell cracking in investment casting with laser stereolithography patterns. Rapid Prototyping J 5(1):12–20

Jones S, Yuan C (2003) Advances in shell moulding for investment casting. J Mater Process Technol 135(2):258–26

Young AC, Omatete OO (1991) Gelcasting of alumina. J Am Ceram Soc 74(3):612–618

Guo D, Cai K, Nan C, Li LT, Gui ZL (2002) Gelcasting based solid freeform fabrication of piezoelectric ceramic objects. Scr Mater 47(6):383–388

Wu HH, Li DC, Guo NN (2009) Fabrication of integral ceramic mold for investment casting of hollow turbine blade based on stereolithography. Rapid Prototyping J 15(4):232–237

Wu H, Li D, Tang Y, Guo N, Cui F, Sun B (2009) Rapid casting of hollow turbine blades using integral ceramic moulds. Proc Inst Mech Eng PART B J Eng Manufacture 223(6):695–702

Wu HH, Li DC, Chen XJ, Sun B, Xu DY (2010) Rapid casting of turbine blades with abnormal film cooling holes using integral ceramic casting molds. Int J Adv Manuf Technol. doi:10.1007/s00170-009-2502-0

Tong WH, Shen FM, Shibata H, Wang WZ, Yang YS (2002) Measurement of heat-transfer coefficient of refractory for BF. Acta Metall Sinica 38(9):983–988

Liu XQ, Wang YS (2003) Mathematical model on the design of the SiO2/epoxy resin thermal expansion coefficient graded materials and stress analysis of FGM plates. J Funct Mater 34(4):426–428

Li B (2003) Research on preparation process of quick precision casting titanium shell based on SL prototypes [D]. Xi’an Jiaotong University, China

Cheng CJ, Zhu YY (2005) Elastic mechanics [M]. Shanghai University Press, Shanghai

Zhang Y, Guo EZ (2004) Heat transfer [M]. Southeast University Press, Nanjing

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, X., Li, D., Wu, H. et al. Analysis of ceramic shell cracking in stereolithography-based rapid casting of turbine blade. Int J Adv Manuf Technol 55, 447–455 (2011). https://doi.org/10.1007/s00170-010-3064-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-010-3064-x