Abstract

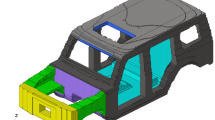

In the early design phase of vehicles, performing lightweight design of body-in-white (BIW) using shape, size and topology optimization is a challenge. The large amount of design parameters including size, shape of cross-sections and positions of various parts are the main contributors to the challenge, which will lead to the huge computational cost for running a large number of finite element (FE) simulations and function evaluations. To handle this problem, an efficient lightweight design strategy which integrates implicit parameterization technique, global sensitivity analysis (GSA) and Pareto set pursuing (PSP) algorithm is proposed in this paper to explore the lightweight design of BIW. Firstly, a full parameterized model of BIW is established with implicit parametrization technique via SFE-CONCEPT. Secondly, the GSA technique is used to reduce the dimensions of design space. Finally, the parameterized model of BIW is optimized by PSP method directly in the reduced design space. It is clearly shown that the optimized BIW structure signifies the noticeable improvement from the baseline model. The results demonstrate that the proposed method is capable in generating a well-distributed Pareto optimal frontier, and can largely reduce the design complexity of BIW lightweight.

Similar content being viewed by others

References

Almeida AT (2012) Multi-criteria model for selection of preventive maintenance intervals. Qual Reliab Eng Int 28:585–593

Arwade SR, Moradi M, Louhghalam A (2010) Variance decomposition and global sensitivity for structural systems. Eng Struct 32(1):1–10

Bojanowski C, Kulak RF (2011) Multi-objective optimization and sensitivity analysis of a paratransist bus structure for rollover and side impact tests. Int J Crashworthiness 16(6):665–676

Catrinu MD, Nordgård DE (2011) Integrating risk analysis and multi-criteria decision support under uncertainty in electricity distribution system asset management. Reliab Eng Syst Saf 96:663–670

Chen VCP, Tsui KL, Barton RR (2006) A review on design, modeling and applications of computer experiments. IIE Trans 38(4):273–291

Chiandussi G, Avalle M (2002) Maximization of the crushing performance of a tubular device by shape optimization. Comput Struct 80:2425–2432

Chiandussi G, Bugeda G, Onate E (2000) Shape variable definition with C0, C1 and C2 continuity functions. Comput Methods Appl Mech Eng 188(4):727–742

Chuang CH, Yang RJ, Li G, Mallela K, Pothuraju P (2008) Multidisciplinary design optimization on vehicle tailor rolled blank design. Struct Multidiscip Optim 35(6):551–560

Coello CAC, Pulido GT, Lechuga MS (2004) Handling multiple objectives with particle swarm optimization. Evol Comput IEEE Trans 8(3):256–279

Cui XT, Zhang HW, Wang SX, Zhang LH, Ko JH (2011) Design of lightweight multi-material automotive bodies using new material performance indices of thin-walled beams for the material selection with crashworthiness consideration. Mater Des 32:815–821

Deb, K., Pratap, A., Agarwal, S., Meyarivan, T., 2002. A fast and elitist multiobjective genetic algorithm: NSGA-II. Evolutionary Computation, IEEE Transactions, 6, 182-197

Deb A, Mahendrakumar MS, Chavan C, Karve J, Blankenburg D, Storen S (2004) Design of an aluminium-based vehicle platform for front impact safety. Int J Impact Eng 30:1055–1079

Doke P, Fard M, Jazar R (2012) Vehicle concept modeling: a new technology for structures weight reduction. Procedia Eng 49:287–293

Donders S, Takahashi Y, Hadjit R, Van Langenhove T, Brughmans M, Van Genechten B, Desmet W (2009) A reduced beam and joint concept modeling approach to optimize global vehicle body dynamics. Finite Elem Anal Des 45(6–7):439–455

Duan SY, Tao YR, Han X, Yang XJ, Hou SJ, Hu ZP (2014) Investigation on structure optimization of crashworthiness of fiber reinforced polymers materials. Compos Part B 60:471–478

Duan LB, Sun GY, Cui JJ, Tao C, Cheng AG, Li GY (2016) Crashworthiness design of vehicle structure with tailor rolled blank. Struct Multidiscip Optim 53(2):321–338

Duddeck F, Zimmer H (2012) New achievements on implicit parameterization techniques for combined shape and topology optimization for crashworthiness based on sfe concept. Shape and Topology Optimization for Crashworthiness. ICRASH2012

Eskandari H, Geiger CD (2008) A fast Pareto genetic algorithm approach for solving expensive multi-objective optimization problems. J Heuristics 14:203–241

Farkas L, Canadas C, Donders S (2009) Optimization study of a parametric vehicle bumper subsystem under multiple load cases using LMS Virtual. Lab and OPTIMUS. In: Proceedings 7th European LS-DYNA conference, Salzburg

Ferreira RJ, de Almeida AT, Cavalcante CA (2009) A multi-criteria decision model to determine inspection intervals of condition monitoring based on delay time analysis. Reliab Eng Syst Saf 94:905–912

Forsberg J, Nilsson L (2006) Evaluation of response surface methodologies used in crashworthiness optimization. Int J Impact Eng 32(5):759–777

Georgios K, Dimitrios S (2009) Multi-disciplinary design optimization exploiting the efficiency of ANSA-LSOPT-META coupling. In: Proceedings 7th European LS-DYNA conference, Salzburg

Goede M, Stehlin M, Rafflenbeul L, Kopp G, Beeh E (2009) Super light car-lightweight construction thanks to a multi-material design and function integration. Eur Transp Res Rev 1(1):15–20

Gu JC, Li GY, Dong Z (2012) Hybrid and adaptive meta-model-based global optimization. Eng Optim 44(1):87–104

Hesse SH, Lukaszewicz DH-JA, Duddeck F (2015) A method to reduce design complexity of automotive composite structures with respect to crashworthiness. Compos Struct 129:236–249

Hilmann J, Paas M, Haenschke A, Vietor T (2007) Automatic concept model generation for optimization and robust design of passenger cars. Adv Eng Softw 38(11–12):795–801

Homma T, Saltelli A (1996) Importance measures in global sensitivity analysis of nonlinear models. Reliab Eng Syst Saf 52(1):1–17

Hou SJ, Li Q, Long SY, Yang XJ, Li W (2007) Design optimization of regular hexagonal thin-walled columns with crashworthiness criteria. Finite Elem Anal Des 43(6):555–565

Hou SJ, Li Q, Long SY, Yang XJ, Li W (2008) Multiobjective optimization of multi-cell sections for the crashworthiness design. Int J Impact Eng 35(12):1355–1367

Khokhar ZO, Vahabzadeh H, Ziai A, Wang GG, Menon C (2010) On the performance of the PSP method for mixed-variable multi-objective design optimization. ASME J Mech Des 132(7):071009

Kopp R, Wiedner C, Meyar A (2005) Flexible rolling for load-adapted blanks. Int Sheet Met Rev 7(4):20–24

Li Y, Lin Z, Jiang A, Chen G (2003) Use of high strength steel sheet for lightweight and crashworthy car body. Mater Des 24(3):177–182

Li GY, Xu FX, Huang XD, Sun GY (2015) Topology optimization of an automotive tailor-welded blank door. J Mech Des 137(5):055001

Liu Q, Lin YZ, Zong JZ, Sun GY, Li Q (2013) Lightweight design of carbon twill weave fabric composite body structure for electric vehicle. Compos Struct 97:231–238

Mundo D, Hadjit R, Donders S, Brughmans M, Mas P, Desmet W (2009) Simplified modelling of joints and beam-like structures for BIW optimization in a concept phase of the vehicle design process. Finite Elem Anal Des 45:456–462

Pan F, Zhu P (2011) Lightweight design of vehicle front end structure: contributions of multiple surrogates. Int J Veh Des 57(2–3):124–147

Pan F, Zhu P, Zhang Y (2010) Metamodel-based lightweight design of B-pillar with TWB structure via support vector regression. Comput Struct 88(1–2):36–44

Pan F, Zhu P, Chen W, Viana FAC (2013) Lightweight design of vehicle parameters under crashworthiness using conservative surrogate. Comput Ind 64(3):280–289

Park JS (1994) Optimal Latin-hypercube designs for computer experiments. J Stat Plan Infer 39(1):95–111

Park DK, Jang CD (2010) Optimum SUV bumper system design considering pedestrian performance. Int J Automot Technol 11(6):819–824

Park DK, Jang CD, Lee SB, Heo SJ, Yim HJ, Kim MS (2010) Optimizing the shape of a bumper beam section considering pedestrian protection. Int J Automot Technol 11(4):489–494

Rais-Rohani M, Solanki K, Eamon C (2006) Reliability-based optimization of lightweight automotive structures for crashworthiness. Proceedings of the 11th AIAA/ISSMO Multidisciplinary Analysis and Optimization Conference 6–8 September 2006, Portsmouth, Virginia

Rayamajhi M, Hunkeler S, Duddeck F (2014) Geometrical compatibility in structural shape optimization for crashworthiness. Int J Crashworthiness 19(1):42–56

Reuter U, Liebscher M (2008) Global sensitivity analysis in view of nonlinear structural behavior. In: LS-DYNA Anwenderforum, Bamberg, Germany; 2008

Shahi SK, Wang GG, An LQ, Bibeau E, Pirmoradi Z (2012) Using the Pareto set pursuing multiobjective optimization approach for hybridization of PHEV. J Mech Des 134:094503–1

Shan S, Wang GG (2005) An efficient Pareto set identification approach for multi-objective optimization on black-box functions. Trans ASME J Mech Des 127(5):866–874

Simon Xu (2007) Use of topology design exploration and parametric shape optimization process to development highly efficient and lightweight vehicle body structure[C/CD]// GM Global CAE Conference, Sep 15, 2007. General Motors Corporation. Detroit, America

Sobol’ IM (1993) Sensitivity estimates for nonlinear mathematical models. Math Model Comput Exp (Engl Transl) 1:407–414

Sobol’ IM (2001) Global sensitivity indices for nonlinear mathematical models and their Monte Carlo estimates. Math Comput Simul 55(1–3):271–280

Sobol’ IM (2003) Theorems and examples on high dimensional model representation. Reliab Eng Syst Saf 79(2):187–193

Sudret B (2008) Global sensitivity analysis using polynomial chaos expansions. Reliab Eng Syst Saf 93(7):964–979

Sun GY, Li GY, Zhou SW, Li HZ, Hou SJ, Li Q (2011) Crashworthiness design of vehicle by using multiobjective robust optimization. Struct Multidiscip Optim 44:99–110

Torstenfelt B, Klarbring A (2007) Conceptual optimal design of modular car product families simultaneous using size, shape and topology optimization. Finite Elem Anal Des 43:1050–1061

Volz K, Frodl B, Dirschmid F, Stryczek R, Zimmer F (2007) Optimizing topology and shape for crashworthiness in vehicle product development. International Automotive Body Congress (IABC), 17–19, June 2007

Wang GG, Simpson TW (2004) Fuzzy clustering based hierarchical meta-modeling for space reduction and design optimization. Eng Optim 36:313–335

Wang GC, Duan LB, Chen ZK, Chen JS (2015) Body-in-white load path planning method based on progressive space topology optimization technique. China Mech Eng 26(20):2827–2834

Xu FX, Sun GY, Li GY, Li Q (2013) Crashworthiness design of multi-component tailor-welded blank (TWB) structures. Struct Multidiscip Optim 48:653–667

Xu FX, Sun GY, Li GY, Li Q (2014a) Experimental investigation on high strength steel (HSS) tailor-welded blanks (TWBs). J Mater Process Technol 214:925–935

Xu FX, Sun GY, Li GY, Li Q (2014b) Experimental study on crashworthiness of tailor-welded blank (TWB) thin-walled high-strength steel (HSS) tubular structures. Thin-Walled Struct 74:12–27

Yin HF, Wen GL, Hou SJ, Chen K (2011) Crushing analysis and multiobjective crashworthiness optimization of honeycomb-filled single and bitubular polygonal tubes. Mater Des 32(8–9):4449–4460

Zhang Y, Lai XM, Zhu P, Wang WR (2006) Lightweight design of automobile component using high strength steel based on dent resistance. Mater Des 27(1):64–68

Zhou G, Ma ZD, Gu JC, Li GY, Cheng AG, Zhang W (2016a) Design optimization of a NPR structure based on HAM optimization method. Struct Multidiscip Optim 53(3):635–643

Zhou G, Ma ZD, Li GY, Cheng AG, Duan LB, Zhao WZ (2016b) Design optimization of a novel NPR crash box based on multi-objective genetic algorithm. Struct Multidiscip Optim 54:673-684

Zimmer H (2010) SFE-CONCEPT reference manual v4.2. Berlin, Germany: SFE-GmbH

Zuo W (2013) An object-oriented graphics interface design and optimization software for cross-sectional shape of automobile body. Adv Eng Softw 64:1–10

Zuo W (2015) Bi-level optimization for the cross-sectional shape of a thin-walled car body frame with static stiffness and dynamic frequency stiffness constraints. J Automob Eng 229(8):1046–1059

Zuo WJ, Li WW, Xu T, Xuan SY, Na JX (2012) A complete development process of finite element software for body-in-white structure with semi-rigid beams in.NET framework. Adv Eng Softw 45(1):261–271

Acknowledgements

This work was supported by the Key Project of National Natural Science Foundation of China under the grant NO. 61232014), and the National Natural Science Foundation of China under the grant NO. 11202072 and 11602054.

Author information

Authors and Affiliations

Corresponding authors

Appendix A. Review of Sobol’s method

Appendix A. Review of Sobol’s method

Let I n = [0,1]n represents n-dimensional unit hypercube and x = [x 1,…,x n ] is an n-dimensional design vector defined in the unit hypercube I n. According to Ref. (Sobol’ 2003), f(x) can be decomposed as

(A. 1) is called ANOVA-representation of f(x), and

According to (A. 2), the members in (A. 1) are orthogonal which can be expressed as integrals of f(x). Indeed,

and so on.

According to (A. 1) and integral operations, we have

The total and partial variances can be respectively expressed as

According to (A. 4), the total variance D can thus be decomposed into partial variances \( {D}_{i_1\cdots {i}_s} \) associated with x 1, x 2,…, x n as

It should be noted that f(x) and \( {f}_{i_1\cdots {i}_s}\left({x}_{i_1},\cdots, {x}_{i_s}\right) \) are random variables with variances D and \( {D}_{i_1\cdots {i}_s} \), respectively.

The first-order, k-order sensitivity indices and the total sensitivity index for the ith design variable are respectively given by

where D − i is the sum of all \( {D}_{i_1\cdots {i}_k} \) terms without the i-th variable. The first-order sensitivity index represents the main effect of a design variable, and higher-order sensitivity indices can capture the effects of interactions among design variables.

Let x i be the i-th variable of x, x − i = {x 1, ⋯ x (i − 1), x (i + 1), ⋯, x n } is the set of n-1 complementary variables and x = [x i , x -i ]. According to Ref. (Sobol’ 1993), D i can be calculated as

Similarly, D -i can be calculated as

For computational expensive engineering problems, multi-dimensional integrals are necessary to obtain the Sobol’ indices when an exact form of the response is not available. Thus, Monte Carlo Sampling (MCS) is used to approximate the integrals. From (A. 3), (A. 5), (A. 7) and (A. 9), the mean value, total and partial variances can be numerically estimated by using MCS efficiently. Consider two independent random points π 1 and π 2 that uniformly distribute in I n, and let π 1 = (x (1) i , x (1)− i ), π 2 = (x (2) i , x (2)− i ), the model f(x) can be evaluated by two points: f(x (1) i , x (1)− i ) and f(x (1) i , x (2)− i ).

Crude Monte Carlo estimation is obtained accurately if N → ∞:

where N is the number of sample points generated by Monte Carlo method (N = 100000 is selected in this paper), x (1m)− i = {x (1m)1 , ⋯, x (1m)(i − 1) , x (1m)(i + 1) , ⋯, x (1m) n } represents the set of n-1 complementary variables for the m-th sample point and x (1m) i is the i-th variable for the m-th sample point.

According to (A. 7), the main effect and the total sensitivity index (total effect) for the i-th design variable can be respectively given by

Rights and permissions

About this article

Cite this article

Duan, L., Xiao, Nc., Hu, Z. et al. An efficient lightweight design strategy for body-in-white based on implicit parameterization technique. Struct Multidisc Optim 55, 1927–1943 (2017). https://doi.org/10.1007/s00158-016-1621-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00158-016-1621-0