Abstract

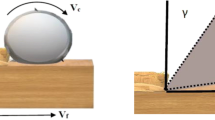

The outer cell layers of a machined solid wood surface usually collapse and compact during processing due to the cutting forces. This layer is called deformation zone. The deformation zone is excessively instable, varies with temperature and MC variation of the environment. Usual surface investigations like surface roughness or surface tension measurements provide only few and indirect information about the status of the deformation zone, although this is the layer to adhere. Suggestion is made to consider the behaviour of the deformation zone during wetting instead of single parameters, in order to better characterize the status of the surface and its expected reaction when treated with water based materials. In this research, the focus has been on describing the behavior of the deformation zone of precision planed and thermosmoothed solid wood surfaces during wetting with distilled water. An individual wetting procedure has been developed, whilst surfaces have been characterized by 3D roughness measurement. The evaluation has been performed after defining the convenient roughness parameter as indicator of surface topography changes of the deformation zone due to wetting. Based on indicators sequence has been set among wood species and machining types regarding the answer given by their deformation zone to wetting. Although the two cutting methods offer the smoothest machined surface, their stability to wetting with water differs considerably. The deformation zone of precision planed surfaces has been proven to be more stable than the one of thermosmoothed surfaces. Black locust preserved its stability even when thermosmoothed.

Similar content being viewed by others

References

Brown CA, Johnsen WA, Hult KM (1998) Scale-sensitivity, fractal analysis and simulations. Int J Mach Tools Manuf 38(5–6):633–637

Csanády E, Magoss E (2012) Mechanics of wood machining. Springer, Berlin

Csiha Cs, Gurau L (2011) Study on the influence of surface roughness on the adhesion of water based PVAC. In: Proceedings of international conference “wood science and engineering”, Brasov, pp 411–419

Csiha Cs, Krisch J (2000) Vessel filtration—a method for analysing wood surface roughness of large porous species. Drevarsky Vyskum 45(1):13–22

DIN EN ISO 25178-2:2012 (2012) Geometrical product specifications (GPS)—surface texture: areal—part 2: terms, definitions and surface texture parameters (Standards catalogue, online http://www.iso.org/iso/home/store/catalogue)

Dong WP, Sullivan PJ, Stout KJ (1994) III Parameters for characterising amplitude and some functional properties. In: Comprehensive study of parameters for characterising three-dimensional surface topography. WEAR 178, pp 29–43

Fischer R, Schuster C (1993) Zur Qualitätsentstehung spanend erzeugter Holzoberflächen. Mitteilung aus dem Institute für Holztechnik der TU Dresden, pp 28–32

Fuchs I (2011) Thermo-smoothing of wood and wood materials—recent results. In: 20th International wood machining seminar, Skellefteå, pp 61–64

Fuchs I, Raatz C, Peter M, Pflüger T (2007) Thermo-mechanical processing of wood materials and effect on the surface roughness. In: Proceedings of third international symposium on wood machining, pp 11–21

GFM (2008) MikroCAD Optical 3D-measuring Instrument Software ODSCAD 6.0. Handbook

Gottlöber C (2014) Zerspanung von Holz und Holzwerkstoffen. (Chipping of wood and wood based products) (in German). In: Grundlagen—Systematik—Modellierung—Prozessgestaltung. Fachbuchverlag Leipzig im Carl Hanser Verlag, München, p 225

Gurau L, Mansfield-Williams H, Irle M (2005) Processing roughness of sanded wood surfaces. Holz Roh Werkst 63(1):43–52

http://www.michmet.com/3d_s_hybrid_parameters.htm Accessed 15 Oct 2015

Özdemir T, Hiziroglu S (2007) Evaluation of surface quality and adhesion strength of treated solid wood. J Mater Process Technol 186(1):311–314

Raatz C, Sandig C (1999) Smoothing of wood and wood based materials. In: 14th international wood machining seminar, pp 83–87

Westkämper E, Riegel A, Kisselbach A, Schadoffsky O (1997a) Gefügeschädigungen als Standzeitkriterium? Teil III (Microstructure damages as lifetime criterion? Part III) (in German). HK Holz- und Kunststoffverarbeitung 32(11):80–82

Westkämper E, Riegel A, Kisselbach A, Schadoffsky O (1997b) Gefügeschädigungen als Standzeitkriterium? Teil I (Microstructure damages as lifetime criterion? Part I) (in German). HK Holz- und Kunststoffverarbeitung 32(9):47–49

Westkämper E, Riegel A, Kisselbach A, Schadoffsky O (1997c) Gefügeschädigungen als Standzeitkriterium? Teil II (Microstructure damages as lifetime criterion? Part II) (in German). HK Holz- und Kunststoffverarbeitung 32(10):43–45

Acknowledgements

The authors would like to acknowledge the Human Resource Development Program (HRDOP 3.6.1-16-2016-00018) “Improving the role of research + development + innovation in the higher education through institutional developments assisting intelligent specialization in Sopron and Szombathely” at University of West Hungary for financially supporting this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Molnár, Z., Magoss, E., Fuchs, I. et al. Stability of thermosmoothed and precision planed solid wood surfaces. Eur. J. Wood Prod. 76, 243–249 (2018). https://doi.org/10.1007/s00107-017-1174-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-017-1174-y