Abstract

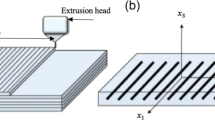

Increasing markets for internet-traded furniture, but also economic concerns are main driving forces to considerably reduce the weight of wood-based furniture panels. Recent research and technological developments have led to an innovative one-step process which simplifies the typical multi-step process for production of foam core panels. Three layered sandwich panels (with particleboard faces and polymeric in situ expanded foam as core layer) can be produced by a one-step process without additional gluing between the face and core layers. As the morphology of the foam and hence its mechanical properties strongly depend on its chemical composition, as well as on the process parameters during expansion, there are no data available, so far, describing the foam of the novel panels. The aim of the proposed project is to determine the elastic properties of in situ expanded foams using 2D digital image correlation. The data can be used later on for the simulation of the elastic behavior of foam core particleboards by means of FEM to describe the short and long term behavior of the panels.

Similar content being viewed by others

References

Allen HG (1969) Analysis and design of structural sandwich panels. Pergamon, Oxford

Almeida OD, Lagattu F, Brillaud J (2008) Analysis by a 3D DIC technique of volumetric deformation gradients: application to polypropylene/EPR/talc composites. Compos Part A-APPL S 39(8):1210–1217

Choi D, Thorpe JL, Hanna RB (1991) Image analysis to measure strain in wood and paper. Wood Sci Technol 25(4):251–262

Fang Z, Wang TJ, Li HM (2006) Large tensile deformation behavior of PC/ABS alloy. Polymer 47(14):5174–5181

Fathi A, Keller JH, Altstaedt V (2015) Full-field shear analyses of sandwich core materials using digital image correlation (DIC). Compos Part B-Eng 70:156–166

Gibson LJ, Ashby MF (1997) Cellular solids: structure and properties, 2nd edn. Cambridge University Press, Cambridge

Godara A, Raabe D, Bergmann I, Putz R, Müller U (2009) Influence of additives on the global mechanical behavior and the microscopic strain localization in wood reinforced polypropylene composites during tensile deformation investigated using digital image correlation. Compos Sci Tech 69(2):139–146

Gredia M (2004) The use of full-field measurement methods in composite materials characterization: interest and limitations. Compos Part A-APPL S 35:751–761

Hamilton AR, Thomsen OT, Madaleno LAO, Jensen LR, Rauhe JCM, Pyrz R (2013) Evaluation of the anisotropic mechanical properties of reinforced polyurethane foams. Compos Sci Tech 87:210–217

Hassel BL, Berard P, Modén CS, Berglund LA (2009) The single cube apparatus for shear testing—full-field strain data and finite element analysis of wood in transverse shear. Compos Sci Tech 69(7–8):877–882

Hild F, Roux S (2006) Digital image correlation: from displacement measurement to identification of elastic properties—a review. Strain 42(2):69–80

Imre B, Renner K, Pukanszky B (2014) Interactions, structure and properties in poly(lactic acid)/thermoplastic polymer blends. Express Polym Lett 8(1):2–14

Järvelä P (1986) A method to measure the fusion strength between expanded polystyrene (EPS) beads. J Mater 21(9):3139–3142

Jerabek M, Major Z, Lang RW (2010) Strain determination of polymeric materials using digital image correlation. Polym Test 29:407–416

Jones E (2015) Documentation for Matlab-based DIC Code. University of Illinois at Urbana-Champaign, http://www.mathworks.com

Luedtke L (2011) Entwicklung und Evaluierung eines Konzepts für die kontinuierliche Herstellung von Leichtbauplatten mit polymerbasiertem Kern und Holzwerkstoffdecklagen. Development and evaluation of a concept for the continuous production of lightweight panels comprising a polymer core and wood-based panel facings (in German), Dissertation, Hamburg University, Germany

Magistris FD, Lennart S (2004) Combined shear and compression analysis using the Iosipescu device: analytical and experimental studies of medium density fibreboard. Wood Sci Technol 37(6):509–521

Mahfuz H, Islam MS, Rangari VK, Saha MC, Jeelani S (2004) Response of sandwich composites with nanophased cores under flexural loading. Compos Part B-Eng 35:543–550

Mantau U, Saal U, Prins K, Steierer F, LindnerM Verkerk H, Eggers J, Leek N, Oldenburger J, Asikainen A, Anttila P (2010) Real potential for changes in growth and use of EU forests. Final report of EUwood, Hamburg, Germany

Paoletti S, Spinelli M, Amico M (2012) The European market for RTA furniture. Centre for Industrial Studies, Milano MI, Italy

Parsons E, Boyce MC, Parks DM (2004) An experimental investigation of the large-strain tensile behavior of neat and rubber-toughened polycarbonate. Polymer 45(8):2665–2684

Perez JG, Santana O, Martinez AB, Maspoch MLI (2008) Use of extensometers on essential work of fracture (EWF) tests. Polym Testing 27(4):491–497

Pierron F (2010) Identification of Poisson’s ratios of standard and auxetic low density polymeric foams from full-field measurements. J Strain Anal Eng 45(4):233–250

Rastogi PK (2000) Photomechanics: topics in applied physics. Springer, Berlin

Rinde JA (1970) Poisson’s ratio for rigid plastic foams. J Appl Poly Sci 14:1913–1926

Rossacci J, Shivkumar S (2003) Influence of EPS bead fusion on pattern degradation and casting formation in the lost foam process. J Mater Sci 38:2321–2330

Shalbafan A, Welling J, Luedtke J (2012) Effect of processing parameters on mechanical properties of lightweight foam core sandwich panels. Wood Mater Sci Eng 7(2):69–75

Shalbafan A, Welling J, Luedtke J (2013a) Effect of processing parameters on physical and structural properties of lightweight foam core sandwich panels. Wood Mater Sci Eng 8(1):1–12

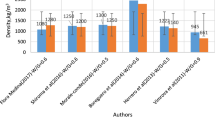

Shalbafan A, Luedtke J, Welling J, Fruehwald A (2013b) Physiomechanical properties of ultra-lightweight foam core particleboards: different core densities. Holzforschung 67(2):69–175

Tscharnuter D, Jerabek M, Major Z, Lang RW (2011) Time-dependent poisson’s ratio of polypropylene compounds for various strain histories. Mech Time-Depend Mat 15(1):15–28

Voiconi T, Linul E, Marsavina L, Sadowski T, Knec M (2014) Determination of flexural properties of rigid PUR foams using digital image correlation. Sol St Phen 216:116–121

Yoon Y, Plummer CJG, Thoemen H, Manson JAE (2016) Liquid CO2 processing of solid polylactide foam precursors. J Cell Plast 52(2):153–174

Zhang S, Dulieu-Barton JM, Fruehmann RK, Thomsen OT (2012) A methodology for obtaining materials properties of polymeric foam at elevated temperatures. Exp Mech 52(1):3–15

Zink A (1995) Image correlation for measuring strain in wood and wood-based composites. Wood Fiber Sci 27(4):346–359

Acknowledgments

Ali Shalbafan would like to acknowledge the Swiss National Science Foundation (SNSF) through the awarded grant (IZK0Z2_162531) to him. The authors are also grateful to Joze Smole, Bern University of Applied Sciences, for panel’s preparation. We also thank Sunpor GmbH and BASF for supplying materials.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shalbafan, A., Rhême, M. & Thoemen, H. Ultra-light particleboard: characterization of foam core layer by digital image correlation. Eur. J. Wood Prod. 75, 43–53 (2017). https://doi.org/10.1007/s00107-016-1088-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-016-1088-0