Abstract

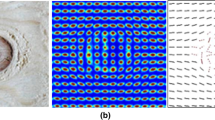

Knots and the orientation of fibres in timber are decisive for the stiffness and strength of boards. Due to large property variations between members, strength grading is necessary. High resolution information of the orientation of fibres, both on surfaces and within members, would enable development of more accurate grading methods than those available today. A step towards three-dimensional (3D) models of the fibre orientation of the entire board volume is the establishment of 3D knot models based on scanning. The light from a dot laser illuminating the surface of a softwood board will, due to the tracheid effect, spread more along the fibres than across resulting in the dot entering an elliptical shape. In this investigation both the shape of the ellipse and the direction of its major axis were used to estimate the 3D fibre orientation on board surfaces. Knot surfaces were identified where the angle between the estimated 3D fibre direction and an approximated direction of the board’s pith exceeded a threshold value. By means of algorithms based on polar coordinates, knot surfaces which belonged to the same physical knot visible on different sides of the board were identified and as a result the position, orientation and volume of each knot were determined. Based on this information, a more accurate position of the board’s pith along the board was calculated. The established models showed good agreement with physical boards. The models constitute a promising starting point for further development of strength grading methods based on tracheid-effect scanning.

Similar content being viewed by others

References

Boughton G (1994) Superior sorting of timber using localized stiffness on edge. In: Proceedings of the Pacific Timber Engineering Conference, Gold Coast, Australia, July 11–15

Dinwoodie JM (2000) Timber: its nature and behavior, 2nd edn. E & FN Spon, London

Dynalyse AB (2015) Precigrader. http://dynalyse.se/precigrader/ (2 June 2015)

EN 384 (2010) Structural timber—determination of characteristic values of mechanical properties and density. European Committee for Standardization

Foley C (2001) A three-dimensional paradigm of fiber orientation in timber. Wood Sci Technol 35(5):453–465

Foley C (2003) Modeling the effect of knots in structural timber. Doctoral thesis, Division of Structural Engineering, Report TVBK-1027, Lund Institute of Technology, Lund, Sweden

Goodman JR, Bodig J (1978) Mathematical model of the tension bahaviour of wood with knots and cross grain. In: Proceedings of the First International Conference on Wood Fracture, Banff, Alberta, Canada, 14–16 August

Guindos P, Guaita M (2013) A three-dimensional wood material model to simulate the behavior of wood with any type of knot at the macro-scale. Wood Sci Technol 47(3):585–599

Hankinson RL (1921) Investigation of crushing strength of spruce at varying angles of grain. Air Service Information Circular, 3(259), Material Section Report No 130, US Air Service, USA

Hatayama Y (1984) A new estimation of structural lumber considering the slope of the grain around knots. Bull For For Prod Res Inst Jpn No 326:69–167 (in Japanese)

Hoffmeyer P (ed.) (1995) Styrkesortering ger mervärde, Del 2—Tillgaengelig teknik (Strength grading adds value, Part 2—Available technique). Laboratoriet for Bygningsmaterialer, Danmarks Tekniske Universitet, Teknisk Rapport 335-1995, ISSN 0908-3871 (in Danish, Norwegian and Swedish)

Innovativ Vision AB (2015) WoodEye. http://woodeye.se/ (16 June 2015)

Johansson C-J (2003) Grading of timber with respect to mechanical properties. In: Thelandersson S, Larsen HJ (eds) Timber engineering. Wiley, Chichester, pp 23–43

Kollman FFP, Côté WA (1968) Principles of wood science and technology. Springer Verlag, Berlin

Lang R, Kaliske M (2013) Description of inhomogeneities in wooden structures: modelling of branches. Wood Sci Technol 47(5):1051–1070

Lukacevic M, Füssl J, Eberhardsteiner J (2015) Discussion of common and new indicating properties for the strength grading of wooden boards. Wood Sci Technol 49:551–576

Matthews PC, Beech BH (1976) Method and apparatus for detecting timber defects. US Patent no. 3676384A

Nagai H, Murata K, Nakano T (2011) Strain analysis of lumber containing a knot during tensile failure. J Wood Sci 57:114–118

Olsson A, Oscarsson J (2014) Three dimensional fibre orientation models for wood based on laser scanning utilizing the tracheid effect. In: Proceedings of World Conference on Timber Engineering, Quebec City, Canada, August 10–14

Olsson A, Oscarsson J, Serrano E, Källsner B, Johansson M, Enquist B (2013) Prediction of timber bending strength and in-member cross-sectional stiffness variation on the basis of local wood fibre orientation. Eur J Wood Prod 71(3):319–333

Ormarsson S (1999) Numerical analysis of moisture-related distortions in sawn timber. Doctoral thesis, Department of Structural Mechanics, Publication 99:7, Chalmers University of Technology, Gothenburg, Sweden

Oscarsson J, Olsson A, Enquist B (2014) Localized modulus of elasticity in timber and its significance for the accuracy of machine strength grading. Wood Fiber Sci 46(4):489–501

Petersson H (2010) Use of optical and laser scanning techniques as tools for obtaining improved FE-input data for strength and shape stability analysis of wood and timber. In: Proceedings of V European Conference on Computational Mechanics, Paris, France, May 16–21

Phillips GE, Bodig J, Goodman JR (1981) Flow-grain analogy. Wood Sci 14(2):55–64

Shigo AL (1997) A new tree biology: facts, photos and philosophies on trees and their problems and proper care. Eight printing. Shigo and Trees, Associates. Durham, NE, US

Simonaho S-P, Palvianien J, Tolonen Y, Silvennoinen R (2004) Determination of wood grain direction from laser light scattering pattern. Opt Lasers Eng 41:95–103

Soest J, Matthews P, Wilson B (1993) A simple optical scanner for grain defects. In: Proceedings of 5th International Conference on Scanning Technology and Process Control for the Wood Products Industry, Atlanta, USA, October 28–29

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Briggert, A., Olsson, A. & Oscarsson, J. Three-dimensional modelling of knots and pith location in Norway spruce boards using tracheid-effect scanning. Eur. J. Wood Prod. 74, 725–739 (2016). https://doi.org/10.1007/s00107-016-1049-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-016-1049-7