Abstract

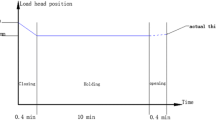

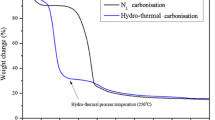

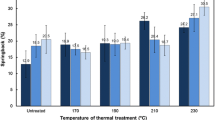

Needle fir (Abies nephrolepis) wood was surface densified at two compression ratios (16.1 and 21.7 %), two hot-pressing temperatures (160 and 180 °C) for a pressure holding duration of 10 min. Subsequently, it was thermally treated at two temperatures (180 and 200 °C) for 1 h. The equilibrium moisture content responses and radial swelling strain ratios were calculated for thirteen types of adsorption specimens under adsorption and water soaking, respectively. Compared with untreated (control) specimens and densified but non-thermally treated ones, the hygroscopicity of thermally post-treated specimens was significantly decreased. Both hot-pressing temperature and compression ratio showed insignificant influence on the hygroscopicity of all treated specimens. Under the current test conditions, with the increase of thermal post-treatment temperature and the decrease of compression ratio among the thermally post-treated specimens, the radial swelling deformation was significantly decreased. The impact of increasing hot-pressing temperature on the radial swelling was insignificant according to the statistical analysis.

Similar content being viewed by others

References

Avramidis S (1989) Evaluation of “three-variable” models for the prediction of equilibrium moisture content in wood. Wood Sci Technol 23(3):251–258

Bonigut J, Krug D, Stuckenberg P (2014) Dimensional stability and irreversible thickness swell of thermally treated oriented strandboards (OSB). Eur J Wood Prod 72(5):593–599

Borrega M, Kärenlampi PP (2010) Hygroscopicity of heat-treated Norway spruce (Picea abies) wood. Eur J Wood Prod 68(2):233–235

Cai JB, Ding T, Yang L, Yang X (2012) Effect of heat treatment and densification on dimension stability of Poplar wood (in Chinese). China Wood Ind 26(5):41–44

Cai JB, Yang X, Cai LP, Shi (2013) Impact of the combination of densification and thermal modification on dimensional stability and hardness of poplar lumber. Drying Technol 31(10):1107–1113

Chaouch M, Dumarcay S, Petrissans A, Gerardin P (2013) Effect of heat treatment intensity on some conferred properties of different European softwood and hardwood species. Wood Sci Technol 47(4):663–673

Ding T, Gu LB, Li T (2011) Influence of steam pressure on physical and mechanical properties of heat-treated Mongolian pine lumber. Eur J Wood Prod 69(1):121–126

Frühwald E (2007) Effect of high-temperature drying on properties of Norway spruce and larch. Holz Roh Werkst 65(6):411–418

Gong M, Lamason C, Li L (2010) Interactive effect of surface densification and post-heat-treatment on aspen wood. J Mater Process Technol 210(2):293–296

Gündüz G, Aydemir D (2009) Some physical properties of heat-treated hornbeam (Carpinus betulus L.) wood. Drying Technol 27(5):714–720

Gündüz G, Niemz P, Aydemir D (2008) Changes in specific gravity and equilibrium moisture content in heat-treated fir (Abies nordmanniana subsp. bornmülleriana Mattf.) Wood. Drying Technol 26(9):1135–1139

Hill CAS, Ramsay J, Keating B, Laine K, Rautkari L, Hughes M, Constant B (2012) The water vapour sorption properties of thermally modified and densified wood. J Mater Sci 47(7):3191–3197

Kamdem DP, Pizzi A, Jermannaud A (2002) Durability of heat treated wood. Holz Roh Werkst 60(1):1–6

Kutnar A, Kamke FA (2012a) Influence of temperature and steam environment on set recovery of compressive deformation of wood. Wood Sci Technol 46(5):953–964

Kutnar A, Kamke FA (2012b) Compression of wood under saturated steam, superheated steam, and transient conditions at 150, 160 and 170 °C. Wood Sci Technol 46(1–3):73–88

Kutnar A, Kamke FA, Sernek M (2009) Density profile and morphology of viscoelastic thermal compressed wood. Wood Sci Technol 43(1–2):57–68

Kutnar A, Rautkari L, Laine K, Hughes M (2012) Thermodynamic characteristics of surface densified solid Scots pine wood. Eur J Wood Prod 70(5):727–734

Laine K, Rautkari L, Hughes M, Kutnar A (2013a) Reducing the set-recovery of surface densified solid Scots pine wood by hydrothermal post-treatment. Eur J Wood Prod 71(1):17–23

Laine K, Belt T, Rautkari L, Ramsay J, Hill CAS, Hughes M (2013b) Measuring the thickness swelling and set-recovery of densified and thermally modified Scots pine solid wood. J Mater Sci 48(24):8530–8538

Liu H, Kamke FA, Guo K (2013) Integrated drying and thermo-hydro-mechanical modification of western hemlock veneer. Eur J Wood Prod 71(2):173–181

Rautkari L, Honkanen J, Hill CAS, Ridley-Ellis D, Hughes M (2014) Mechanical and physical properties of thermally modified Scots pine wood in high pressure reactor under saturated steam at 120, 150 and 180 & #xB0;C. Eur J Wood Prod 72(1):33–41

Sik HS, Choo KT, Zakaria S, Ahmad S, How SS, Chia CH, Yusoff M (2010) Dimensional stability of high temperature-dried rubberwood solid lumber at two equilibrium moisture content conditions. Drying Technol 28(9):1083–1090

Tjeerdsma BF, Boonstra M, Pizzi A, Tekely P, Militz H (1998) Characterisation of thermally modified wood: molecular reasons for wood performance improvement. Holz Roh Werkst 56(3):149–153

Todaro L, Zanuttini R, Scopa A, Moretti N (2012) Influence of combined hydro-thermal treatments on selective properties of Turkey oak (Quercus cerris L.) wood. Wood Sci Technol 46(3):563–578

Tu DY, Wang MJ, Gu LB et al (2010) Effect of super high temperature heat treatment on Fraxinus mandshurica board’s dimension stability (in Chinese). J Nanjing Forest Univ (Natural Science Edition) 34(3):113–116

Welzbacher CR, Wehsener J, Rapp AO, Haller P (2008) Thermo-mechanical densification combined with thermal modification of Norway spruce in industrial scale—Dimensional stability and durability aspects. Holz Roh Werkst 66(1):39–49

Zhan JF, Gu JY, Cai YC (2009) Dynamic visco-elastic characteristics of larch timber during conventional drying process (in Chinese). J Beijing Forest Univ 31(1):129–134

Zhan JF, Cao J, Gu JY et al (2015) Surface-densification and high-temperature hydrothermal post treatment of the Abies nephrolepis lumber (in Chinese). J Nanjing Forest Univ (Natural Science Edition) 39(3):119–124

Acknowledgments

This research was financially supported by the Fundamental Research Funds for the Central Universities of China (Northeast Forestry University, No. DL13CB17).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhan, Jf., Avramidis, S. Needle fir wood modified by surface densification and thermal post-treatment: hygroscopicity and swelling behavior. Eur. J. Wood Prod. 74, 49–56 (2016). https://doi.org/10.1007/s00107-015-0969-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-015-0969-y