Abstract

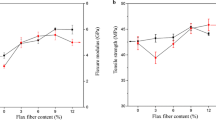

This research studied the influence of formulations of wood-plastic composites on dynamic mechanical properties—storage modulus (E′), loss modulus (E′′) and mechanical loss factor (tan δ)—according to dynamic mechanical analysis spectra. The specimens were made with wood flour, high-density polyethylene (HDPE) and maleic anhydride polypropylene as a coupling agent. Generally, the presence of fillers and a coupling agent in polymer affect the relaxation processes and produce a more complex morphology, thereby influencing the mechanical and viscoelastic properties of the composites. In this work, the addition of a higher content of wood flour resulted in higher values of E′, indicating a better stiffness, but tan δ decreased. The bonding agent significantly improved E′, which can be attributed to an enhanced interface between the wood and the HDPE. Coupled products had better E′ retention at elevated temperatures than uncoupled samples. The addition of wood flour and a coupling agent increased the value of E′, but did not significantly change the range of relaxation transition.

Similar content being viewed by others

References

Balasuriya PW, Ye L, Mai YW (2003) Morphology and mechanical properties of reconstituted wood board waste-polyethylene composites. Compos Interface 10(2–3):319–341

Benthien JT, Ohlmeyer M (2013) Thickness swelling and water absorption of WPC after immersion in cold and boiling water. Eur J Wood Prod 71(4):437–442

Chang F-C, Lam F, Englund KR (2010) Feasibility of using mountain pine beetle attacked wood to produce wood-plastic composites. Wood Fiber Sci 42(3):388–397

Chartoff RP, Weissman PT, Sircar A (1994) The application of dynamic mechanical methods to Tg determination in polymers: an overview. In: Seyler RJ (ed) Assignment of the Glass Transition. American Society for Testing and Materials, Philadelphia, pp 88–107

Chen J, Gardner DJ (2008) Dynamic mechanical properties of extruded nylon-wood composites. Polym Compos 29(4):372–379

Chowdhury MA, Wolcott MP (2007) Compatibilizer selection to improve mechanical and moisture properties of extruded wood-HDPE composites. For Prod J 57(9):46–53

Clemons CM, Ibach RE (2004) Effects of processing method and moisture history on laboratory fungal resistance of wood-HDPE composites. For Prod J 54(4):50–57

Hwang GS, Hsiung JC (2000) Durability of plastics/wood composite boards manufactured with waste wood particles. Taiwan J For Sci 15(2):201–208

Lu JZ, Wu Q, McNabb HS Jr (2000) Chemical coupling in wood fiber and polymer composites: a review of coupling agent and treatments. Wood Fiber Sci 32(1):88–104

Mahieux CA, Reifsnider KL (2002) Property modeling across transition temperature in polymers: application to filled and unfilled polybutadiene. J Elastom Plast 34:79–89

Mortezaei M, Famili MHN, Kokabi (2011) The role of interfacial interactions on the glass-transition and viscoelastic properties of silica/polystyrene nanocomposite. Compos Sci Technol 71(8):1039–1045

Samal SK, Mohanty S, Nayak SK (2009) Polypropylene–bamboo/glass fiber hybrid composites: fabrication and analysis of mechanical, morphological, thermal, and dynamic mechanical behavior. J Reinf Plast Comp 28(22):2729–2747

Santos EF, Mauler RS, Nachtigall SMB (2009) Effectiveness of maleated- and silanized-PP for coir fiber-filled composites. J Reinf Plast Comp 28(17):2119–2129

Selke SE, Wichman I (2004) Wood fiber/polyolefin composites. Compos Part A Appl S 35(3):321–326

Sepe MP (1998) Dynamic mechanical analysis for plastic engineering. Plastic Design Library, Norwich, NY

Sirotkin RO, Brooks NW (2001) The dynamic mechanical relaxation behavior of polyethylene copolymers cast from solution. Polymer 42:9801–9808

Son J, Gardner DJ, O’Neill S, Metaxas C (2003) Understanding the viscoelastic properties of extruded polypropylene wood plastic composites. J Appl Polym Sci 89:1638–1644

Stark NM, Matuana LM, Clemons CM (2004) Effect of processing method on surface and weathering characteristics of wood-flour/HDPE composites. J Appl Polym Sci 93:1021–1030

Swaminathan G, Shivakumar K (2009) A re-examination of DMA testing of polymer matrix composites. J Reinf Plast Comp 28(8):979–994

Tajvidi M, Falk RH, Hermanson, JC, Felton C (2003) Influence of natural fibers on the phase transitions in high-density polyethylene composites using dynamic mechanical analysis. In: Seventh International Conference on Woodfiber-Plastic Composites. Forest Product Society, Madison, WI, 19–20 May 2007, pp 187–195

Tajvidi M, Motie N, Rassam G, Falk RH, Felton C (2010) Mechanical performance of hemp fiber polypropylene composites at different operating temperatures. J Reinf Plast Comp 29(5):664–674

Verhey SA, Laks PE (2002) Wood particle size affects the decay resistance of woodfiber/thermoplastic composites. For Prod J 52(11/12):78–81

Acknowledgments

The authors acknowledge Forestry Innovation Investment Ltd., British Columbia, Canada, for providing financial support to this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chang, FC., Kadla, J.F. & Lam, F. The effects of wood flour content and coupling agent on the dynamic mechanical and relaxation properties of wood-plastic composites. Eur. J. Wood Prod. 74, 23–30 (2016). https://doi.org/10.1007/s00107-015-0962-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-015-0962-5