Abstract

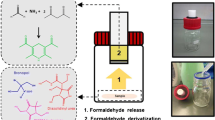

The perforator method is a widely accepted standard method for evaluating formaldehyde contents in medium-density fiber board (MDF) and particle board in most countries in the world. However, the test consumes considerable amounts of toluene, which belongs to a category of poisonous organic solutions. This study was conducted to determine the formaldehyde content of MDF accurately by high-performance liquid chromatography (HPLC), a method that uses significantly less amounts of organic solvents for extraction than other methods. Five extraction solvents, namely, ethyl acetate, acetonitrile, methyl alcohol, dichloromethane, and petroleum ether, were used in the experiment. 2,4-Dinitrophenylhydrazine (DNPH) derivatization and HPLC analysis coupled with UV detection were conducted. Optimum micro-extraction was obtained by using acetonitrile, especially formaldehyde contents below 6 mg/100 g. Three parallel tests demonstrated good average recoveries ranging from 95.4 to 97.9 % and low relative standard deviations ranging from 1.1 to 2.9 %, which is indicative of very high accuracy. A 0.02 mg/100 g limit of detection was also obtained. The formaldehyde–DNPH derivatives remained stable for at least 48 h under ambient conditions, which indicates the applicability of the proposed method in the laboratory.

Similar content being viewed by others

References

Air Resources Board Method 430 (1991) Determination of formaldehyde and acetaldehyde in emissions from stationary sources. California Environmental Protection Agency, Sacramento

AS/NZS 4266.15 (1995) Reconstituted wood-based panels—methods of test-Determination of formaldehyde (perforator method). Australian/New Zealand Standard

ASTM D 5197 (2009) Standard Test Method for Determination of Formaldehyde and Other Carbonyl Compounds in Air (Active Sampler Methodology). ASTM International, West Conshohocken

BS EN 120 (1984, re 1992) Standard addition recovery test Wood based panels Determination of formaldehyde content Extraction method called the perforator method. British Standards Institution

BS EN 717-1 (2004) Wood-based panels-determination of formaldehyde release-Part 1: formaldehyde emission by the chamber method. British Standards Institution

Bulian F, Battaglia R, Ciroi S (2003) Formaldehyde emission from wood based panels the importance of intercalibrating the test methods. Holz Roh- Werkst 61:213–215

Burini G, Coli R (2004) Determination of formaldehyde in spirits by highperformance liquid chromatography with diode-array detection after derivatization. Anal Chim Acta 511:155–158

GB/T 17657 (1999, re 2013) Test methods of evaluating the properties of wood-based panels and surface decorated wood-based panels. Chinese Standard

Geise GM, Falcon LP, Freeman BD, Paul DR (2012) Sodium chloride sorption in sulfonated polymers for membrane applications. J Membr Sci 423–424(15):195–208

GOST 27678 (1988) Wood particle boards. Perforator method for determining formaldehyde content. Gosudarstvennye Standarty State Standard GOST (Russian)

Irakli MN, Samanidou VF, Biliaderis CG, Papadoyannis IN (2012) Development and validation of an HPLC-method for determination of free and bound phenolic acids in cereals after solid-phase extraction. Food Chem 134(3):1624–1632

ISO 12460-5 (2011) Wood-based panels-determination of formaldehyde release-Part 5: extraction method (called the perforator method). ISO International Organization for Standardization

Jones SB, Terry CM, Lister TE, Johnson DC (1999) Determination of submicromolar concentrations of formaldehyde by liquid chromatography. Anal Chem 71:4030–4033

Roffael E, Mehlhorn L (1980) Influence of marginal conditions on the determination of extractable formaldehyde by the perforator method (In German). Holz Roh- Werkst 38:85–88

Soman A, Qiu Y, Chan Li Q (2008) HPLC–UV method development and validation for the determination of low level formaldehyde in a drug substance. J Chromatogr Sci 46:461–465

Wang T, Gao XL, Tong J, Chen LG (2012) Determination of formaldehyde in beer based on cloud point extraction using 2,4-dinitrophenylhydrazine as derivative reagent. Food Chem 131:1577–1582

Xu X, Su R, Zhao X, Liu Z, Li D, Li XY, Zhang HQ, Wang ZM (2011) Determination of formaldehyde in beverages using microwave-assisted derivatization and ionic liquid-based dispersive liquid-liquid microextraction followed by high-performance liquid chromatography. Talanta 85(5):2632–2638

Acknowledgments

This work was financially supported by Special Fund for Forest Scientific Research in the Public Welfare (201304501) and HYPERLINK “javascript:void(0);” Zhejiang HYPERLINK “javascript:void(0);” Province and Chinese Academy of Forestry cooperation projects (2014SY11).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yu, H., Yang, L., Xu, M. et al. Feasibility of micro-extraction and subsequent HPLC analysis for evaluating the extractable formaldehyde content of medium-density fiber board. Eur. J. Wood Prod. 73, 801–806 (2015). https://doi.org/10.1007/s00107-015-0945-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-015-0945-6