Abstract

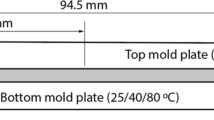

Residual stresses were predicted by a flow analysis in the mold cavity and residual stress distribution in the injection molded product was measured. Flow field was analyzed by the hybrid FEM/FDM method, using the Hele Shaw approximation. The Modified Cross model was used to determine the dependence of the viscosity on the temperature and the shear rate. The specific volume of the polymer melt which varies with the pressure and temperature fields was calculated by the Tait’s state equation. Flow analysis results such as pressure, temperature, and the location of the liquid-solid interface were used as the input of the stress analysis. In order to calculate more accurate gap-wise temperature field, a coordinate transformation technique was used. The residual stress distribution in the gap-wise direction was predicted in two cases, the free quenching and the constrained quenching, under the assumption that the shrinkage of the injection molded product occurs within the mold cavity and that the solid polymer is elastic. Effects of the initial flow rate, packing pressure, and mold temperature on the residual stress distribution was discussed. Experimental results were also obtained by the layer removal method for molded polypropylene.

Similar content being viewed by others

References

G. D. Gilmore and R. S. Spencer,Modern Plastics,27(8), 143 (1950).

R. S. Spencer and G. D. Gilmore,J. Colloid Sci.,6, 1118 (1951).

C. A. Hieber and S. F. Shen,J. Non-Newt. Fluid Mech.,7, 1 (1980).

H. H. Chiang, C. A. Hieber, and K. K. Wang,Polym. Eng. Sci.,31, 116 (1991).

H. H. Chiang, C. A. Hieber, and K. K. Wang,Polym. Eng. Sci.,31, 125 (1991).

W. F. Zoetelief, L. F. A. Douven, and A. J. Ingen Housz,Polym. Eng. Sci.,14, 1886 (1996).

K. M. B. Jansen and G. Titomanlio,Polym. Eng. Sci.,36, 2029 (1996).

K. M. B. Jansen and G. Titomanlio,Polym. Eng. Sci.,36, 2041 (1996).

K. K. Kabanemi, H. Vaillancourt, H. Wang, and G. Salloum,Polym. Eng. Sci.,38, 21 (1998).

R. G. Treuting and W. T. Read Jr.,J. Appl. Phys.,22(2), 130 (1951).

C. H. V. Hastenberg, P. C. Wildervanck, A. J. H. Leenen, and G. G. J. Schennink,Polym. Eng. Sci.,32, 506 (1992).

M. Akay and S. Ozden,J. Mat. Sci.,30, 3358 (1995).

M. Akay and S. Ozden,Polym. Eng. Sci.,13, 1839 (1996).

O. Denizart, M. Vincent, and J. F. Agassant,J. Mat. Sci.,30, 552 (1995).

V. Leo and C. H. Cuvelliez,Polym. Eng. Sci.,15, 1961 (1996).

C. S. Kwok, L. Tong, and J. R. White,Polym. Eng. Sci.,5, 65 (1996).

K. M. B. Jansen, J. J. Orij, C. Z. Meijer, and D. J. V. Dijk,Polym. Eng. Sci.,39, 10 (1999).

A. I. Isayev, “Injection and Compression Molding Fundamentals”, Marcel Dekker, New York, 1987.

S. C. Lee and J. R. Youn,J. Reinf. Plas. Comp.,18, 186 (1999).

J. H. Jung, S. W. Lee, and J. R. Youn,Macromolecular Symposia,148, 263 (1999).

Y. I. Kwon, M. S. Thesis, Seoul National University, Seoul, 1999.

J. Crank, “Free and Moving Boundary Problems”, pp. 163–282, Clarendon Press, Oxford, 1987.

H. See,Korea-Australia Rheology J.,13, 67 (2001).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kwon, Y.I., Kang, T.J., Chung, K. et al. Prediction and measurement of residual stresses in injection molded parts. Fibers Polym 2, 203–211 (2001). https://doi.org/10.1007/BF02875346

Received:

Revised:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02875346