Abstract

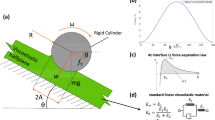

A simple one-dimensional, axisymmetric model of a gas-pressure deformation calorimeter containing a lumped heat source accounts for observed pressure changes in terms of conductive and radiant components of heat transfer. Agreement is generally good between experimental data and the predicted calorimeter response for the range of source dimensions, heating rates, and test temperatures investigated in the study.

Zusammenfassung

Ein einfaches eindimensionales axensymmetrisches Modell eines Gasdruck-Deformationskalorimeters erklärt die beobachteten Druckänderungen in Abhängigkeit der leitenden und strahlenden Komponenten des Wärmetransportes. Für die vorliegend untersuchten Bereiche von Strahlungsquellenabmessungen, Aufheizgeschwindigkeiten und Testtemperaturen wird im allgemeinen eine gute Übereinstimmung zwischen experimentellen Daten und vorausgesagter Kalorimeterwirkung beobachtet.

Similar content being viewed by others

Abbreviations

- Ai :

-

Surface area of the heat source

- Ao :

-

Surface area of the calorimeter cell wall

- β:

-

Dimensionless ratio of radiant to conduction terms

- C:

-

Heat capacity of heat source

- εi, εo :

-

Emissivity of source and cell wall, respectively

- G(x):

-

Derived geometric quantity relating gas pressure change to source and cell parameters

- G(0):

-

Value of G(x) at x=0, i.e. line source

- kg :

-

Thermal conductivity of gas in calorimeter

- ks :

-

Thermal conductivity of heat source in the calorimeter

- lo, l:

-

Sample length in the undeformed and deformed state, respectively

- L:

-

Calorimeter cell length= 0.287 m

- γ:

-

Principle stretch ratio of sample in loading direction, γ=l/lo

- Po :

-

Atmospheric pressure=1 bar=100 KPa

- δP(t):

-

Instantaneous gas pressure change in calorimeter resulting from heat flow

- ρ:

-

Temperature difference between the source and calorimeter cell wall

- \(\dot Q_i^o \) :

-

Total heat flow from source (constant)

- \(\dot Q_i \) :

-

Total heat flow from source (variable)

- \(\dot Q_c \) :

-

Heat flow from source due to conduction

- \(\dot Q_r \) :

-

Radiant heat flow from source

- ri :

-

Source radius

- ro :

-

Calorimeter cell radius=11.1 mm

- ∂:

-

Density of heat source

- σ:

-

Stefan-Boltzmann radiation constant

- Ti :

-

Heat source temperature

- To :

-

Calorimeter cell wall temperature

- τ:

-

Time constant of source

- Vi :

-

Volume of source

- Ω:

-

Electrical resistance of heating wires

- x:

-

Dimensionless ratio of source to cell radii

- ζ:

-

Time variable of integration

References

R. E. Lyon and R. J. Farris, Rev. Sci. Inst., 57 (1986) 1640.

R. E. Lyon, Thermodynamics of Deformation, Ph. D. Thesis, University of Massachusetts, Amherst, MA, 1985.

R. E. Lyon and R. J. Farris, Polym. Eng. Sci., 24 (1984) 908.

J. P. Holman, Heat Transfer, McGraw-Hill 1963, Chapter 8.

R. E. Lyon and R. J. Farris, Thermochim. Acta, 161 (1990) 287.

D. R. Pitts and L. E. Sissom, Theory and Problems of Heat Transfer, McGraw-Hill Book Company, NY 1977, Appendix B.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lyon, R.E., Raboin, P.J. Heat transfer in deformation calorimeters. Journal of Thermal Analysis 44, 777–793 (1995). https://doi.org/10.1007/BF02547264

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02547264