Abstract

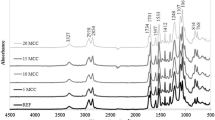

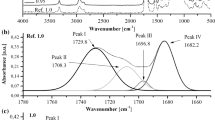

The aim of this work was to obtain bio-based polyurethane composites using biocomponents such as, bio-glycol, modified natural oil-based polyol, and microcrystalline cellulose (MCC). The prepolymer method was used to prepare the bio-based polyurethane matrix. Prepolymer synthesised from 4,4′-diphenylmethane diisocyanate and a polyol mixture containing 75 wt% commercial polyether and 25 wt% hydroxylated soybean oils (H3) was later subjected to chain extension polymerization with bio-1,3-propanediol acting as a chain extender . Different composites were produced by dispersing 5, 10, 15 and 20 wt% of microcrystalline cellulose powder in the polyurethane matrix. The polymerization reaction was catalyzed with 1,4-diazabicyclo[2.2.2]octane. The influence of MCC content on the structure and the mechanical and thermo-mechanical properties of the obtained bio-based polyurethane composites was investigated. The FTIR analysis demonstrated that the addition of MCC did not significantly change the chemical structure of the obtained composites. The SEM images showed good interfacial adhesion between the bio-filler and the partially bio-based matrix of the composites. The results of thermo-mechanical analysis demonstrated that the application of MCC filler affected the storage and loss moduli. The tensile strength and elongation at break decreased with increasing MCC content. Moreover, the addition of MCC improved the hardness of the obtained environmentally friendly materials.

Similar content being viewed by others

References

Aranguren MI, Marcovich NE, Salgueiro W, Somoza A (2013) Effect of the nano-cellulose content on the properties of reinforced polyurethanes. A study using mechanical tests and positron annihilation spectroscopy. Polym Test 32:115–122

Ashori A (2008) Wood—plastic composites as promising green-composites for automotive industries. Biores Technol 99:4661–4667

Auad ML, Contos VS, Nutt S, Aranguren MI, Marcovich NE (2008) Characterisation of nanocellulose reinforced shape memory polyurethanes. Polym Int 57:651–659

Auad ML, Mosiewicki MA, Richardson T, Aranguren MI, Marcovich NE (2010) Nanocomposites made from cellulose nanocrystals and tailored segmented polyurethanes. J Appl Polym Sci 115:1215–1225

Bledzki AK, Gassan J (1999) Composites reinforced with cellulose based fibres. Prog Polym Sci 24:221–274

Cataldi A, Dorigato A, Deflorian F, Pegoretti A (2014) Thermo-mechanical properties of innovative microcrystalline cellulose filled composites for art protection and restoration. J Mater Sci 49(5):2035–2044

Datta J, Głowińska E (2011) Influence of cellulose on mechanical and thermomechanical properties of elastomers obtained from mixtures containing natural rubber. Polimery 11(12):823–827

Datta J, Głowińska E (2014) Effect of hydroxylated soybean oil and bio-based propanediol on the structure and thermal properties of synthesised bio-polyurethanes. Ind Crop Prod 61:84–91

Dimitrov KV, Herzog M, Nenkova S (2013) Fe3O4 modification of microcrystalline cellulose for composite materials. Am J Chem 3(5):140–147

Faruk O, Bledzki AK, Fink H-P, Sain M (2012) Biocomposites reinforced with natural fibers: 2000–2010. Prog Polym Sci 37:1552–1596

Głowińska E, Datta J (2014) A mathematical model of rheological behavior of novel bio-based isocyanate-terminated polyurethane prepolymers. Ind Crop Prod 60:123–129

Haafiz MKM, Hassan A, Zakaria Z, Inuwa IM, Islam MS (2013) Physicochemical characterization of cellulose nanowhiskers extracted from oil palm biomass microcrystalline cellulose. Mater Lett 113:87–89

Hatakeyama H, Kato N, Nanbo T, Hatakeyama T (2012) Water absorbent polyurethane composites derived from molasses and lignin filled with microcrystalline cellulose. J Mater Sci 47:7254–7261

Ismail EA, Motawie AM, Sadek EM (2011) Synthesis and characterisation of polyurethane coatings based on soybean oil-polyester polyols. Egypt J Petrol 20:1–8

Jankauskaitė V, Abzalbekuly B, Lisauskaitė A, Procyčevas I, Fataraitė E, Vitkauskienė A, Janakhmetov U (2014) Silicone rubber and microcrystalline cellulose composites with antimicrobial properties. Mater Sci 20(1):42–49

Kiziltas A, Gardner D, Han Y, Yang HS (2011a) Thermal properties of microcrystalline cellulose-filled PET-PTT blend polymer composites. J Therm Anal Calorim 103(1):163–170

Kiziltas A, Gardner DJ, Han Y, Yang HS (2011b) Dynamic mechanical behavior and thermal properties of microcrystalline cellulose (MCC)-filled Nylon 6 composites. Thermochim Acta 519:38–43

Larkin P (2010) Infrared and Raman Spectroscopy. Principles and Spectral Interpretation, Elsevier, Connecticut

Lopes RVV, Osorio LFB, Santos ML, Sales MJA (2012) Characterisation of polyurethanes from vegetable oils by TG/DTG, DMA and FT-IR. Macromol Symp 319:173–178

Luo X, Mohantya A, Misraa M (2013) Lignin as a reactive reinforcing filler for water-blown rigid biofoam composites from soy oil-based polyurethane. Ind Crops Prod 47:13–19

Marcovich NE, Auad ML, Bellesi NE, Nutt SR, Aranguren MI (2006) Cellulose micro/nanocrystals reinforced polyurethane. J Mater Res 21:870–881

Miao S, Liu Y, Wang P, Zhang S (2012) Castor oil and microcrystalline cellulose based polymer composites with high tensile strength. Adv Mater Res 399(401):1531–1535

Mosiewicki MA, Casado U, Marcovich NE, Aranguren MI (2009) Polyurethanes from tung oil: polymer characterization and composites. Polym Eng Sci 49(4):685–692

Panaitescu DM, Notingher PV, Ghiurea M, Ciuprina F, Paven H, Iorga M, Florea D (2007) Properties of composite materials from polyethylene and cellulose microfibrils. J Optoelectron Adv Mater 9(8):2524–2528

Pandey JK, Nakagaito AN, Takagi H (2013) Fabrication and applications of cellulose nanoparticle-based polymer composites. The Free Library (January, 1), http://www.thefreelibrary.com/Fabrication and applications of cellulose nanoparticle-based polymer.-a0314444342. Accessed 27 Aug 2014

Park SH, Oh KW, Kim SH (2013) Reinforcement effect of cellulose nanowhisker on bio-based polyurethane. Compos Sci Technol 86:82–88

Patricio PS, Pereira IM, Ferreira da Silva NC, Ayres E, Pereira FV, Oréfice RL (2013) Tailoring the morphology and properties of waterborne polyurethanes by the procedure of cellulose nanocrystal incorporation. Eur Polym J 49:3761–3769

Picker KM, Hoag SW (2002) Characterisation of the thermal properties of microcrystalline cellulose by modulated temperature differential scanning calorimetry. J Pharm Sci 91(2):342–349

Prisacanu C (2011) Polyurethane elastomers from morphology to mechanical aspects. Springer, Wien

Rueda L, Saraleguia A, Fernández d’Arlasa B, Zhoub Q, Berglund LA, Corcueraa MA, Mondragona I, Eceizaa A (2013) Cellulose nanocrystals/polyurethane nanocomposites. Study from the viewpoint of microphase separated structure. Carbohyd Polym 92:751–757

Saralegi A, Gonzalez ML, Valea A, Eceiza A, Corcuera MA (2014) The role of cellulose nanocrystals in the improvement of the shape-memory properties of castor oil-based segmented thermoplastic polyurethanes. Compos Sci Technol 92:27–33

Siró I, Plackett D (2010) Microfibrillated cellulose and new nanocomposite materials: a review. Cellulose 17(3):459–494

Sobczak R, Nitkiewicz Z, Koszkul J (2002) Examination of the dynamic mechanical properties of polypropylene composites reinforced glass fibre. Kompozyty 2(3):78–80

Sun X, Lu C, Liu Y, Zhang W, Zhang X (2014) Melt-processed poly(vinyl alcohol) composites filled with microcrystalline cellulose from waste cotton fabrics. Carbohyd Polym 101:642–649

Wu Q, Henriksson M, Liu X, Berglund LA (2007) A high strength nanocomposite based on microcrystalline cellulose and polyurethane. Biomacromolecules 8(12):3687–3692

Xu Y, Petrović Z, Das S, Wilkes GL (2008) Morphology and properties of thermoplastic polyurethanes with dangling chains in ricinoleate-based soft segments. Polymer 49(9):4248

Yakubu A, Tanko MU, Sani SDM (2011) Chemical modification of microcrystalline cellulose: improvement of barrier surface properties to enhance surface interactions with some synthetic polymers for biodegradable packaging material processing and applications in textile, food and pharmaceutical industry. Adv Appl Sci Res 2(6):532–540

Acknowledgments

The authors wish to thank DuPont Company (USA) and International Fibre Corporation, (Belgium) for kindly providing the bio-glycol and microcrystalline cellulose.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Głowińska, E., Datta, J. Structure, morphology and mechanical behaviour of novel bio-based polyurethane composites with microcrystalline cellulose. Cellulose 22, 2471–2481 (2015). https://doi.org/10.1007/s10570-015-0685-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-015-0685-0