Abstract

The efficiency of granular activated carbon (GAC) was investigated in this study as a catalyst for the elimination of pentachlorophenol (PCP) from contaminated streams in a laboratory-scale semi-batch reactor. The influence of important parameters including solution pH (2–10), radical scavenger (tert-butanol, 0.04 mol/L), catalyst dosage (0.416–8.33 g/L), initial PCP concentration (100–1000 mg/L) and ozone flow rate (2.3–12 mg/min) was examined on the efficiency of the catalytic ozonation process (COP) in degradation and mineralization of PCP in aqueous solution. The experimental results showed that catalytic ozonation with GAC was most effective at pH of 8 with ozone flow rate of 12 mg/min and a GAC dosage of 2 g. Compared to the sole ozonation process (SOP), the removal levels of PCP and COP were, 98, and 79 %, respectively. The degradation rate of kinetics was also investigated. The results showed that using a GAC catalyst in the ozonation of PCP produced an 8.33-fold increase in rate kinetic compared to the SOP under optimum conditions. Tert-butanol alcohol (TBA) was used as a radical scavenger. The results demonstrated that COP was affected less by TBA than by SOP. These findings suggested that GAC acts as a suitable catalyst in COP to remove refractory pollutants from aqueous solution.

Similar content being viewed by others

Introduction

Pentachlorophenol (PCP) is one of the hazardous pollutants extensively used in pesticides, herbicides and wood preservatives. This widespread application could lead to release of PCP into water sources (Öberg et al. 1990). According to US EPA, PCP is one of the prior pollutants whose maximum recommended concentration level in drinking water is 0.001 mg/L. 2, 3, 4, 5, 6 PCP is a white solid which is soluble in water in the range of 10–20 mg/L at room temperature. Even at concentrations less than 0.1 mg/L, this compound is toxic for plants, animals and human beings (Asgari et al. 2014). High levels of PCPs in aqueous environments may be toxic for, and it can also reduce their removal efficiency by the biological processes. Therefore, degradation or removal of PCP contamination often needs chemical and physical techniques. Due to various adverse effects of this compound, several technologies have been used to remove it from aqueous solutions. Advanced oxidation process (AOP) is a new technology used to treat industrial wastewater containing high concentrations of refractory compounds based on generation of very reactive groups, particularly hydroxyl radicals, these processes are used to degrade various organic compounds (Andreozzi et al. 1999). Ozone is a very strong oxidant, but single ozonation process (SOP) performance is not strong enough to remove the organic matter by mineralization because some oxidative reactions are relatively slow and selective. Nowadays, AOPs have been investigated to provide greater ozonation efficiency, the catalytic ozonation is found to be more effective for the removal of several pollutants from aqueous solution. Catalytic ozonation processes (COPs) are recent attractive kinds of AOPs in which various substances are used, as catalysts with the ozone, to generate very strong oxidative radical. (Jung et al. 2007; Moussavi et al. 2009). Based on type of the catalyst, the COPs were classified into homogeneous and heterogeneous processes, with the heterogeneous process having a higher degradation efficiency. (Kasprzyk-Hordern et al. 2003). Nowadays, the capabilities of several materials such as activated carbon, metal ions, metal oxides, natural zeolites and impregnated materials have been investigated as catalyst in COPs (Liotta et al. 2009). In recent years, activated carbon has been taken into huge consideration to be an efficient ozonation catalyst. This adsorbent is added to the ozonation process for the decomposition of O3 and thereby generates reactive radicals such as hydroxyl radicals (Faria et al. 2008). Hydroxyl radicals have high oxidative power in mineralizing refractory organic compounds (Sánchez-Polo et al. 2005).

In this research, GAC was used as a catalyst in catalytic ozonation of PCP from aqueous solutions. In addition, the main objective of this study was to compare and investigate the removal efficiency of PCP by SOP and COP. The catalytic effect of GAC on ozone decomposition and the important parameters (e.g., solution pH, radical scavenger effect, GAC dosage, initial PCP concentration and ozone flow rate) were studied in the COP.

Materials and methods

Materials

The GAC used in this study as catalyst was prepared from German Merck Co. It had a particle size 58°, BET surface area of 155 m2/g. Sodium salt PCP (Na–PCP, purity >98 %) was purchased from Aldrich Co. Concentrated stock solutions of PCP were made by dissolving the PCP powder in sodium hydroxide solutions (0.1 mol/L). Subsequent PCP solutions were prepared at different concentrations by dissolving stock solution in certain amounts of distilled water. All the other reagents such as tert-butanol, 4-aminoantipyrine and potassium-ferro-cyanide were analytical grades without further purification.

Methods

The catalytic ozonation experiments were carried out as a pilot scale in a semi-batch flow reactor. A glass sparger with volume of 1000 mL was used as ozonation, equipped with a sintered-glass diffuser at bottom, an ozone generator and an oxygen generator. Ozone was made using an ozone-making machine, ARDA model COG-OM. Oxygen required for the ozone generator was supplied by oxygen-making machine, model PORSA VF-3 with high purity level and the ability to adjust oxygen injection level. The effect of parameters such as pH, tert-butyl alcohol radical scavenger, catalyst dosage, initial PCP concentration and ozone flow rate was tested in different contact time (10–30 min). In this study, the effect of pH in range of 2–10 was studied on the both SOP and COP (under the selected condition; PCP concentration = 100 mg/L; catalyst dosage = 8.333 g/L; dissolved ozone dosage = 0.49 g/min). In the next step, after the optimum pH was identified, the effect of tert-butanol alcohol was tested as a radical scavenger on the SOP and COP efficiency in removal of PCP. Moreover, to determine optimum concentration of GAC as catalyst in the COP, various concentrations of GAC in range of 0.416–8.33 g/L were tested under selected condition (pH = 8; PCP concentration = 100 mg/L, contact time = 15 min). Also the effects of various concentration of PCP (from 100 to 1000 mg/L) were evaluated on COP efficiency. In the next step, to determine optimum ozone flow rate, changes of ozone flow were studied in range of 2.3–12 mg/min.

The catalytic ozonation potential of the GAC on the degradation of PCP was obtained from subsequent Eq. (1)

To illustrate the effects of GAC on PCP degradation, the degradation kinetics was investigated. The kinetics of degradation in ozonation processes can be written as (Asgari et al. 2013):

However, as CGAC is constant, a second constant phrase can be described as follows:

Subsequently, equation can be written as follows:

K obs represents the pseudo-first-order rate constants (min−1). The data from both COP and SOP fitted well to the pseudo-first-order kinetics. Ksop was calculated via method reported by Asgari et al. (2013). Finally, the COP efficiency under optimum condition in removal of COD was investigated.

Analysis

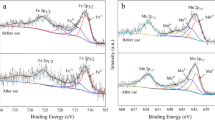

PCP concentrations in solution were measured by colorimetric method using UV–Vis spectrophotometer (DR 5000) in 500 nm wavelength (Asgari et al. 2014). The mass velocity of ozone was measured by standard iodometry; also the values of COD were determined with a standard potassium dichromate oxidation method (Rand et al. 1976). Point zero charge (pHpzc) of activated carbon was determined using the pH drift method. To determine pHzpc, of activated carbon, NaCl solution (0.01 M) was used as an inert electrolyte. HCL and NaOH (0.1 M) were used and the initial pH of solution was adjusted from 2 to 12. The quantities (0.5 g) of GAC were added to each flask. Flasks were placed on the shaker (Model GFL 3017) with 120 rpm for 48 h. Then, the contents of each flask were filtered using 0.45 µm and final pH was measured using pH meter (Hatch Sinsion1). The pHpzc was determined by drawing initial pH versus final pH (Asgari et al. 2014, 2013).

Results and discussion

Influence of initial pH

Since solution pH plays a key role in the oxidation process, in this part of study the effect of solution initial pH (in range of 2–10) was studied on the degradation of PCP. The results of these tests are shown in Fig. 1. As revealed in this figure, the maximum removal efficiency of PCP was obtained at pH 10 and 8 in SOP and COP, respectively, after 30 min. As it can be found from Fig. 1, the maximum removal efficiency of PCP was 98 and 69 % by COP and SOP, respectively. In addition, the minimum removal efficiency of PCP was seen at pH 2 in both COP and SOP. These findings designate that under the selected condition, the oxidation of PCP in both processes increased with the increase of initial pH and reaction time. Additionally, at different pH points, the performance of COP was better in PCP removal than that of SOP, which explains the effect of pH on the properties of catalyst surface (Faria et al. 2008; Li et al. 2009) and on the ozone transfer from the gas phase to the liquid phase and ozone decomposition. In effect, the formation of active oxidant is highly related to the solution pH, so that, at acidic pH the ozone molecules react with compounds with specific functional groups through selective reactions such as electrophilic, nucleophilic and dipolar addition (Xie et al. 2012). In contrast, at alkaline pH, ozone decomposes yielding hydroxyl radicals, which are extremely oxidizing species that react (non-selectively) with a large series of organic and inorganic compounds in aqueous solutions (Xie et al. 2012; Liu et al. 2013) In addition, the obtained results of present study show that the pHpzc of GAC was 8.6. Previous studies suggested that at pH values above than pHpzc hydroxyl groups of GAC surface could be deprotonated. Thus, dissociated surface acid groups might increase the nucleophilic character. In this condition dissociated acid groups that are placed on the GAC surface led to increased reaction rate with ozone (Asgari et al. 2014, 2013). Also, the difference in the rates of PCP degradation at different initial pH values could be attributed to the different structures of PCP of PCP, which may influence the degradation reaction. PCPs in aqueous solution can exist in ionized or non-ionized forms depending on pH, which at pH 2.7 it is only 1 % ionized and at pH 9, the maximum of it is ionized and is easily leachable (Warwick Fisher 1990). Hence, in this research, the oxidation of PCP with ozone was already strong under an alkaline solution. This observation is consistent with the results of reactive red 198 removal in a COP with pistachio hull conducted by Moussavi et al. In the current study, the maximum catalytic potential occurred at alkaline pH of 10 (Moussavi and Khosravi 2012). Also, Zhao et al. observed an increase in the COP efficiency in removal of nitrobenzene with the increase in solution pH (Zhao et al. 2008). In another similar study, the color removal efficiency in the COP was higher than that in SOP, also the COP efficiency increased with the increase of pH. Optimum pH for catalytic oxidation of color in this study was 6.8 (Liu et al. 2013). Therefore, the initial pH of solution significantly affected both COP and SOP.

Influence of radical scavenger

A radical scavenger is a chemical substance added to a reactor to remove or de-activate impurities. Also, these compounds react with the free radicals in the oxidation process that can slow the rate of oxidation. Thus, a radical scavenger can be used as an indicator of hydroxyl radical reactions. To explain the effect of GAC on the generation rate of hydroxyl radicals, the influence of tert-butanol as radical scavengers in COP was studied. Here tert-butanol which has the reaction rate constants of 6 × 108 M−1 S−1 with hydroxyl radicals and 3 × 10−3 M−1 S−1 with ozone was established as scavengers (Andreozzi et al. 1999; Buxton et al. 1998). tert-Butanol solution (0.04 mol/L–2 ml) was added to 120 ml reaction solutions. Figure 2 shows the influence of tert-butanol on the degradation of PCP in catalytic ozonation with GAC. As shown here, after 30 min in the presence of tert-butyl alcohol, the SOP efficiency in PCP removal decreased from 79 to 54 %. In addition, in similar conditions, the efficiency of COP decreased from 95 to 86 %. Therefore, the presences of tert-butanol significantly reduced the degradation rate of PCP in both SOP and COP. However, the effect of radical scavenger on the COP was less than that of SOP. These parts of experiments showed that the COP was less affected by tert-butanol as radical scavengers. This can be attributed to the role of GAC in the COP. In other words, in COP, the GAC provided a contact surface for the adsorption of PCP molecules and subsequent O3 molecules directly oxidized after both of them were adsorbed on the GAC (Liu et al. 2013). Since ozonation in the presence of catalysts like GAC can take place through direct reaction with O3 molecules and indirect reaction with hydroxyl radicals, hence radical scavenger did not affect the COP significantly. These findings are consistent with a study by Xiaoyu et al. who used salicylic acid as radical scavenger in catalytic ozonation of Acid Red B over Fe–Cu–O (Liu et al. 2013). Asgari et al. also observed that heterogeneous ozone decomposition processes were less affected by dissolved radical scavenger (Asgari et al. 2013). In contrast, a different result was taken by Martins and Quinta-Ferreira in catalytic ozonation with Mn–Ce–O in removal of phenolic acids (Martins and Quinta-Ferreira 2009).

Influence of catalyst dosage on degradation

The influence of catalyst dosage in range of 0.416–8.33 g/L on PCP removal in the COP was studied under condition of solution volume of 120 ml and reaction time of 15 min. As shown in Fig. 3, the COP efficiency in removal of PCP in the presence of 0.416 and 8.33 g/L of GAC was 10 and 97.5 %, respectively. Therefore, in catalytic ozonation the degradation of PCP increased with the increase of catalyst dosage. This can be attributed to the greater availability surface site. In addition, the increase of GAC dosage directly affects the degradation of PCP. In the Liu et al. study, the dye and COD removal was 66 and 48 % but when the catalyst was used the removal efficiency increased to 90 and 70 %, respectively (Faria et al. 2008; Liu et al. 2013; Warwick Fisher 1990; Moussavi and Khosravi 2012; Zhao et al. 2008). The optimum dosage of catalyst in the COP depends deeply on the type of catalyst, target compounds, reaction conditions and desired performance. In the present study, the value of 1 g/120 ml (8.33 g/L) was determined as the optimum dosage for GAC in the COP. The increase of PCP degradation with increasing catalyst dosage is associated to the increase of GAC surface area and of active sites available for ozone decomposition; these increases therefore enable enhanced generation of reactive radicals, mainly hydroxyl radical (Liu et al. 2013; Alvarez et al. 2009), resulting in improvement of the PCP removal. Asgari et al. also suggested that the ozone decomposition rate increased with bone charcoal dosage as a catalytic in ozonation process (Asgari et al. 2013).

Influence of initial PCP concentration

Another significant parameter in the COP is initial pollutant concentration entering the reactor, thus it is important to survey how the initial pollutant concentration affects the efficiency of COP. Thus in the present study, COP experiments were carried out on kinetic samples with different initial concentration of PCP in range of 100–1000 mg/L. The results of this part of study are shown in Fig. 4. As it can be seen here, PCP removal efficiency decreased with the increase of PCP initial concentration. According to the results, the removal efficiency of PCP in initial concentration of 100 and 1000 mg/L was 96 and 58.2 % after 30 min, respectively. The increase of PCP initial concentration to 1000 mg/L caused the decrease of COP efficiency in removal of PCP. This can be attributed to the fact that the COP produced only a limited amount of hydroxyl radical, thus the removal efficiency by COP reduced with increasing initial PCP concentration. This result is in accordance with the finding of color removal study conducted by Liu et al.; the results of mentioned study also indicated that the degradation efficiency of color and COD was reduced with increasing color initial concentration (Liu et al. 2013).

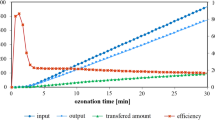

Influence of ozone flow rate

In this step of study, the effect of ozone flow rate in range of 2.3–12 mg/min on the COP efficiency in removal of PCP was studied. As shown in Fig. 5, the minimum removal efficiency of PCP was 17 % in 2.3 mg/min of ozone flow rate, while the maximum efficiency in removal of PCP was 97.6 % in 12 mg/min of ozone flow rate after 15 min, therefore the removal efficiency of PCP by COP increased with the increase of ozone flow rate. Moreover, an ozone flow rate of 12 mg/min was chosen as optimum condition for following experiments.

Evaluation the role of GAC in the COP

In this step of experiments, used GAC in the ozonation process of PCP was investigated as an alternative to fresh one. The obtained results indicated that the removal efficiency of PCP did not decrease obviously compared to that of fresh GAC under the same experimental conditions. This phenomenon demonstrated that the GAC was stable in ozonation process and had high potential to be reused in several times (Sánchez-Polo et al. 2005). These findings are consistent with similar study on the Fe–Cu–O as a used catalyst in the ozonation process of acid red B (Liu et al. 2013). Figure 6 shows the removal efficiency of PCP from aqueous solution by COP, SOP and single GAC (adsorption) process under the same conditions (PCP concentration, pH 8, and 8.33 g/L−1 GAC dosage). The results demonstrate that when GAC and ozonation come together, their synergistic effect increased in PCP degradation. As shown in Fig. 6, the removal efficiency of PCP in COP was 95 % after 30 min, which was about 1.2 and 6.7 times higher than that of SOP and GAC adsorption process (76 and 14 %, respectively). These findings can be related to the role of surface chemistry of GAC on the ozone decomposition. Previous studies reported that in catalytic ozonation in aqueous solution in presence of GAC yields hydroxyl radicals. These radicals arise chiefly from the ozone decomposition on the GAC surface sites, then hydroxyl radicals over GAC oxidized directly the organic compounds in aqueous solution (Alvarez et al. 2009). Therefore, the surface chemistry of GAC plays a significant role in decomposition of ozone in aqueous solution into more reactive radical, then led to increased COP efficiency in removal of PCP. The results show that the similar pattern was seen in other contact times; additionally, it is significant to note that the PCP could not be adsorbed on the surface of GAC catalyst in beginning of the process.

COD removal in COP under optimum conditions

In this study, the removal of COD was measured only in optimal conditions due to lack of funds. The removal of COD by COP was evaluated at optimum conditions (catalyst dosage = 8.33/L and pH = 8). According to Fig. 7, the removal efficiency of COD and PCP by COP was 42 and 50 %, respectively, within the first 10 min. Also as can be found from Fig. 7, after 30 min, the removal efficiency of COD and PCP in aqueous solution was 79 and 98 %, respectively. Therefore, the COD removal was less than that of PCP removal by COP. In addition, the pH values of the solution also were measured during the reaction. As can be observed from Fig. 7, the pH values decreased during the ozonation process and finally reached 2.2; the decrease in pH can be attributed to the acid generated during the process. Some previous studies have found that intermediate species production is formed in the COP and one of the most degradation intermediates was acetic acid. Therefore, the produced acid during COP could lead to the decrease of pH (Liu et al. 2013; Zhao et al. 2008). Thus, the rapid decline in solution pH versus the increase of PCP removal efficiency proves the formation of acidic intermediates in the oxidation of PCP.

Kinetic study

The PCP rates are presented in Table 1. As shown in Table 1, the PCP degradation rate in both processes increased with increasing pH. Table 1 illustrates that the COP process performed better than SOP. At each pH level, GAC had a greater effect on PCP decomposition or degradation rates compared to SOP. The pseudo-first-order rate (ksop) of SOP increased from 0.02 to 0.06 min−1, while the COP Kobs value increased from 0.1 to 0.5 min−1 when pH increased from 5 to 8.33. The ratio of kobs/ksop in acidic conditions is 5. Hence, the presence of GAC increased rate of reaction fivefold in acidic conditions. In alkaline conditions, the Kobs/ksop ratio increased to 7.5 (at pH 8) and 8.33 (at pH 10). This confirms that GAC acts as a catalyst promoting PCP degradation. This data demonstrate that catalytic ozonation with GAC is valuable process in degradation PCP from aqueous solution. The results suggested that the heterogeneous catalytic ozonation process is a suitable process for replacement of SOP and other AOPs (Devi et al. 2014).

Conclusions

The present study has explained the role of GAC as a catalyst in the catalytic ozonation of PCP in aqueous solution. The optimum pH, GAC dosage and ozone flow rate in the COP were determined to be 8, 8.33 g L−1 and 12 mg/min, respectively. This work also demonstrated that the COP was less affected than that of SOP by tert-butanol as radical scavengers. After reusing a used GAC in ozonation process the removal efficiency of PCP did not decrease obviously compared to that of fresh GAC under the same experimental conditions, indicating a stable activity in ozonation process. Moreover, the removal efficiency of PCP in the COP was about 1.2 and 6.7 times higher than that of SOP and GAC adsorption process. In addition, the kinetic models investigated in this study indicated that pseudo-second-order kinetic model gave better results than other models. Therefore, these findings suggested that GAC acts as a suitable catalyst in COPs for removal of refractory pollutants from aqueous solution.

References

Alvarez PM, Beltran FJ, Masa FJ, Pocostales JP (2009) Comparison between catalytic ozonation and activated carbon adsorption/ozone-regeneration processes for waste water treatment. Appl Catal B: Environ 92:393–400

Andreozzi R, Caprio V, Insola A, Marotta R (1999) Advanced oxidation processes (AOP) for water purification and recovery. Catal Today 53(1):51–59

Asgari G, Seid Mohammadi A, Mortazavi SB, Ramavandi B (2013) Investigation on the pyrolysis of cow bone as a catalyst for ozone aqueous decomposition: kinetic approach. J Anal Appl Pyrolysis 99:149–154

Asgari G, Seidmohammadi A, Chavoshani A, Rahmani AR (2014a) Microwave/H2O2 efficiency in pentachlorophenol removal from aqueous solutions. JRHS 14(1):36–39

Asgari G, Seid Mohammadi A, Poormohammadi A, Ahmadian M (2014b) Removal of cyanide from aqueous solution by adsorption onto bone charcoal. Fresenius Environ Bull 23(3):720–727

Buxton GV, Greenstock CL, Helman WP, Ross AB (1998) Critical review of rate constants for reactions of hydrated electrons, hydrogen atoms and hydroxyl radicals. Phys Chem Ref Data 17:513–886

Devi RashmiR, Iohborlang M, Umlong Bodhaditya Das, Borah Kusum, Thakur AshimJ, Raul PrasantaK, Banerjee Saumen, Singh Lokendra (2014) Removal of iron and arsenic(III) from drinking water using iron oxide-coated sand and limestone. Appl Water Sci 4:175–182

Faria PCC, Orfao JJM, Pereira MFR (2008a) A novel ceria-activated carbon composite for the catalytic ozonation of carboxylic acids. Catal Commun 9:2121–2126

Faria PCC, Orfao JJM, Pereira MFR (2008b) Activated carbon catalytic ozonation of oxamic and oxalic acids. Appl Catal B: Environ 79:237–243

Jung H, Park H, Kim J, Lee J-H, Hur H-G, Myung NV et al (2007) Preparation of biotic and abiotic iron oxide nanoparticles (IOnPs) and their properties and applications in heterogeneous catalytic oxidation. Environ Sci Technol 41(13):4741–4747

Kasprzyk-Hordern B, Ziółek M, Nawrocki J (2003) Catalytic ozonation and methods of enhancing molecular ozone reactions in water treatment. Appl Catal B: Environ 46(4):639–669

Li L, Ye W, Zhang Q, Sun F, Lu P, Li X (2009) Catalytic ozonation of dimethyl phthalate over cerium supported on activated carbon. J Hazard Mater 170:411–416

Liotta L, Gruttadauria M, Di Carlo G, Perrini G, Librando V (2009) Heterogeneous catalytic degradation of phenolic substrates: Catalysts activity. J Hazard Mater 162(2):588–606

Liu X, Zhou Z, Jing G, Fang J (2013) Catalytic ozonation of Acid Red B in aqueous solution over a Fe–Cu–O catalyst. Sep Purif Technol 115:129–135

Martins RC, Quinta-Ferreira RM (2009) Catalytic ozonation of phenolic acids over a Mn–Ce–O catalyst. Appl Catal B: Environ 90:268–277

Moussavi G, Khosravi R (2012) Preparation and characterization of a biochar from pistachio hull biomass and its catalytic potential for ozonation of water recalcitrant contaminants. Bioresour Technol 119:66–71

Moussavi G, Khavanin A, Alizadeh R (2009) The investigation of catalytic ozonation and integrated catalytic ozonation/biological processes for the removal of phenol from saline wastewaters. J Hazard Mater 171(1):175–181

Öberg LG, Glas B, Swanson SE, Rappe C, Paul KG (1990) Peroxidase-catalyzed oxidation of chlorophenols to polychlorinated dibenzo-p-dioxins and dibenzofurans. Arch Environ Contam Toxicol 19(6):930–938

Rand M, Greenberg AE, Taras MJ (1976) Standard methods for the examination of water and wastewater: Prepared and published jointly by American Public Health Association, American Water Works Association, and Water Pollution Control Federation

Sánchez-Polo M, Von Gunten U, Rivera-Utrilla J (2005) Efficiency of activated carbon to transform ozone into OH radicals: Influence of operational parameters. Water Res 39(14):3189–3198

Warwick Fisher S (1990) The pH dependent accumulation of PCP in aquatic microcosms with sediment. Aquat Toxicol 18(4):199–217

Xie Q, Dong X, Huang W, Xu H, Du H (2012) Reaction kinetics and thiourea removal by ozone oxidation. EPE 38(3):78–98

Zhao L, Ma J, Sun Z, Zhai X (2008) Catalytic ozonation for the degradation of nitrobenzene in aqueous solution by ceramic honeycomb -supported manganese. Appl Catal B: Environ 83:256–264

Acknowledgments

The authors would like to thank Hamadan University of Medical Science for its financial support.

Conflict of interest

The authors have declared no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Asgari, G., Samiee, F., Ahmadian, M. et al. Catalytic ozonation of pentachlorophenol in aqueous solutions using granular activated carbon. Appl Water Sci 7, 393–400 (2017). https://doi.org/10.1007/s13201-014-0254-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13201-014-0254-y