Abstract

In this work, an experimental investigation was carried out on the grain refinement of molten AA5754 Aluminum alloy through ultrasonic treatment. The cavitation induced heterogeneous nucleation was suggested as the major mechanism for grain refinement in the AA5754 aluminum alloy. A numerical simulation was performed to predict the formation, growth and collapse of cavitation bubbles in the molten AA5754 Aluminum alloy. Moreover, the acoustic pressure distribution and the induced acoustic streaming by ultrasonic horn reactor were investigated. It is suggested that the streaming by ultrasonic could transport the small bubbles formed in the ultrasonic cavitation zone into the bulk of melt rapidly. These micro-bubbles are collapsed due to acoustic vibrations where the resulting micro-jets are strong enough to break the oxide layer and to wet the impurities. These exogenous particles, intermetallics and oxides could contribute to the formation of fine, uniform and equiaxed microstructure across the treated melt. The experimental results confirmed the simulation predictions.

Similar content being viewed by others

References

Z. Fan, S. Ji, and M. J. Bevis, Method and Apparatus for Manufacturing Castings from Immiscible Metallic Liquids, PCT Patent,WO02/13993A1 (Priority date: 11/08/2000).

J. P. Gabathuler, D. Barras, and Y. Krahenbuhl, Evaluation of Various Processes for the Production of Billet with Thixotropic Properties, 2nd International Conference on Semi- Solid Processing of Alloys and Composites, pp.33–46, MIT, Cambridge, USA (1992).

C. Vives, Met. Trans. B. 23B, 189 (1992).

C. Vives, Met. Trans. B. 24B, 493 (1993).

G. Eskin, Ultrasonic Treatment of Light Alloy Melts, Gordon and Breach, Amsterdam (1998).

V. Abramov, O. Abramov, V. Bulgakov, and F. Sommer, Mater. Lett. 37, 27 (1998).

J. Campbell, Int. Met. Rev. 2, 71 (1981).

O. Abramov, Ultrasound in Liquid and Solid Metals, Boca Raton, FL: CRC Press (1994).

O. V. Abramov, High-Intensity Ultrasonics: Theory and Industrial Applications, Gordon and Breach Science Publishers, New York, NY (1998).

G. I. Eskin, Ultrason. Sonochem. 2, 137 (1995).

G. I. Eskin, Ultrason. Sonochem. 8, 319 (2001).

R. Haghayeghi, E. Ezzatneshan, H. Bahai, and L. Nastac, Met. Mater. Int. 19, 959 (2013).

J. Youn and Y. J. Kim, Jpn. J. Appl. Phys. 4807GM14 (5 pages) (2009).

M. C. Schenker, M. J. B. M. Pourquié, D. G. Eskin, and B. J. Boersma, Ultrason. Sonochem 20, 502 (2013).

F. J. Trujillo and K. Knoerzer, Ultrason. Sonochem, 18, 1263 (2011).

ASTM International, Standard Test for Determining Average Grain Size, ASTM International PA, USA (2010).

L. Nastac, 2012 IOP Conf. Ser.: Mater. Sci. Eng. 33, 012079 (2012).

Gambit Tutorial Guide, Release 2.4.6 (2000).

ANSYS Release 14.0, Coupled Field Analysis Guide, ANSYS Inc. (2007).

G. H. Schnerr and J. Sauer, Physical and Numerical Modeling of Unsteady Cavitation Dynamics, Proc. 4th Int. Conf. on Multiphase Flow, New Orleans, USA (2001).

L. Nastac, Modeling and Simulation of Microstructure Evolution in Solidifying Alloys, Springer Verlag, USA (2004).

F. R. Menter, AIAA Journal, 32, 1598 (1994).

O. Coutier-Delgosha, J. L. Reboud, and R. Fortes-Patella, Fluids Engineering 125, 38 (2003).

M. M. Chivate and A. B. Pandit, Ultrason. Sonochem, 2, 19 (1995).

Y. Kojima, Y. Asakura, G. Sugiyama, and S. Koda, Ultrason. Sonochem, 17, 978 (2010).

V. S. Sutkar, P. R. Gogate, and L. Csoka, Chem.Eng. J. 158, 290 (2010).

Author information

Authors and Affiliations

Corresponding author

Additional information

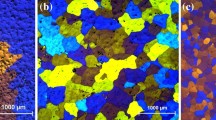

This article has been retracted at the request of the editorial board of Metals and Materials International. The article was examined following the COPE guidelines with regard to suspected plagiarism in a published manuscript. The article contains figures reproduced from a previously published article with no acknowledgement of the source. Fig. 3 has been published previously in: An investigation on physical and chemical refinement of aerospace aluminium alloys R. Haghayeghi, P. Kapranos Mater. Lett. 95 (2013) 121-124 The microstructures in Fig. 3 are reproduced from Fig. 3 (a), (b), (c), while being assigned to different alloys and conditions. The corresponding author R. Haghayeghi submitted the article without the consent of the two co-authors E. Ezzatneshan and H. Bahai. The co-authors also indicate that they did not have knowledge on the previously published data contributed by R. Haghayeghi.

About this article

Cite this article

Haghayeghi, R., Ezzatneshan, E. & Bahai, H. RETRACTED ARTICLE: Grain refinement of AA5754 aluminum alloy by ultrasonic cavitation: Experimental study and numerical simulation. Met. Mater. Int. 21, 109–117 (2015). https://doi.org/10.1007/s12540-014-6015-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-014-6015-5