Abstract

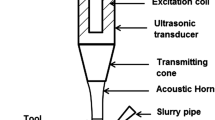

We designed and fabricated suitable vibrational equipment for ultrasonic assisted oblique turning process to enable researchers to perform experimental tests with the operating conditions closest to common assumptions of cutting mechanics theories. Applying ultrasonic vibrations to the tool cutting edge along tangential direction and in the presence of inclination and tool cutting edge angles necessitates a novel design and fabrication of vibrational horn with special oblique geometry. In this vibrational horn, the natural frequency of longitudinal vibration mode is forced to be in a certain frequency range of the ultrasonic power supply. The novel tool-workpiece assembly was designed using modal analysis to provide the most conformity of cutting geometry and process parameters between theory and practice. Three-dimensional cutting forces were measured experimentally in vibrational oblique turning process carried out by the mentioned horn. The most suitable conditions to profit from ultrasonic vibrations in oblique turning process were determined, and these experimental results were in agreement with modal analysis results.

Similar content being viewed by others

References

A. S. Adnan and S. Subbiah, Experimental investigation of transverse vibration-assisted orthogonal cutting of AL-2024, International J. of Machine Tools and Manufacture, 50 (3) (2010) 294–302.

H. Wang, S. To, C. Y. Chan, C. F. Cheung and W. B. Lee, A theoretical and experimental investigation of the tool-tip vibration and its influence upon surface generation in singlepoint diamond turning, International J. of Machine Tools and Manufacture, 50 (2010) 241–252.

H. Soleimanimehr, M. J. Nategh and S. Amini, Modeling of surface roughness in vibration cutting by artificial neural network, International J. of Aerospace and Mechanical Engineering, 4 (3) (2010) 160–155.

S. Amini, H. Soleimanimehr, M. J. Nategh, A. Abudollah and M. Sadeghi, FEM analysis of ultrasonic-vibrationassisted turning and the vibratory tool, J. of Materials Processing Technology, 201 (2008) 43–47.

N. Ahmed, A. V. Mitrofanov, V. I. Babitsky and V. V. Silberschmidt, Analysis of forces in ultrasonically assisted turning, J. of Sound and Vibration, 308 (2007) 845–854.

V. I. Babitsky, A. V. Mitrofanov and V. V. Silberschmidt, Ultrasonically assisted turning of aviation materials: simulations and experimental study, Ultrasonics, 42 (2004) 81–86.

J. Kumabe, K. Fuchizawa, T. Soutome and Y. Nishimoto, Ultrasonic superposition vibration cutting of ceramics, Precision Engineering, 11 (2) (1989) 71–77.

R. Skelton, Effect of ultrasonic vibrations on the turning process, International J. of Machine Tool Design and Research, 9 (4) (1969) 363–374.

K. H. W. Seah, Y. S. Wong and L. C. Lee, Design of tool holders for ultrasonic machining using FEM, J. of Materials Processing Technology, 37 (1-4) (1993) 801–816.

A. Cardoni and M. Lucas, Enhanced vibration performance of ultrasonic block horns, Ultrasonics, 40 (1-8) (2002) 365–369.

J. J. Yang, Z. D. Fang, B. Y. Wei and X. Z. Deng, Theoretical explanation of the ‘local resonance’ in stepped acoustic horn based on Four-End Network method, J. of Materials Processing Technology, 209 (6) (2009) 3106–3110.

M. R. Rani and R. Rudramoorthy, Computational modeling and experimental studies of the dynamic performance of ultrasonic horn profiles used in plastic welding, Ultrasonics, 53 (3) (2013) 763–772.

I. C. Rosca, M. I. Pop and N. Cretu, Experimental and numerical study on an ultrasonic horn with shape designed with an optimization algorithm, Applied Acoustics, 95 (2015) 60–69.

L. Xu, Investigation of a cup-shaped ultrasonic transducer operated in the full-wave vibrational mode, Ultrasonics, 59 (2015) 109–118.

E. Shamoto, N. Suzuki and R. Hino, Analysis of 3D elliptical vibration cutting with thin shear plane model, CIRP Annals - Manufacturing Technology, 57 (2008) 57–60.

M. J. Nategh, H. Razavi and A. Abdullah, Analytical modeling and experimental investigation of ultrasonicvibration assisted oblique turning, part I: Kinematics analysis, International J. of Mechanical Sciences, 63 (2012) 1–11.

H. Razavi, M. J. Nategh and A. Abdullah, Analytical modeling and experimental investigation of ultrasonicvibration assisted oblique turning, part II: Dynamics analysis, International J. of Mechanical Sciences, 63 (2012) 12–25.

E. Shamoto and Y. Altintas, Prediction of shear angle in oblique cutting with maximum shear stress and minimum energy principles, J. of Manufacturing Science and Engineering, 121 (1999) 399–407.

N. Fang, An improved model for oblique cutting and its application to chip-control research, J. of Materials Processing Technology, 79 (1998) 79–85.

L. Meirovitch, Analytical methods in vibrations, London: Macmillan Co., London, UK (1967).

D. M. Stefanescu, Handbook of Force Transducers, Principles and Components, Springer Berlin, Germany (2011).

M. D. Radmanovic and D. D. Manacic, Design and modelling of the power ultrasonic transducers, MPI Company, Switzerland (2004).

M. Lucas, J. N. Petzing, A. Cardonil and L. J. Smith, Design and characterization of ultrasonic cutting tools, CIRP Annals - Manufacturing Technology, 50 (1) (2001) 149–152.

A. I. Markov, Ultrasonic machining of intractable materials, Illife Books, London, UK (1966).

Mechanical properties of steel bolts and screws (Technical Data Chart), Maryland Metrics (http://mdmetric.com/tech/ mech_property_BS3692.pdf).

C. J. Robert and M. M. Kurt, Fundamentals of machine component design, 2nd Ed., Wiley, New York, USA (1991).

H. Razavi, M. J. Nategh and A. Abdullah, Analytical modeling and experimental investigation of ultrasonicvibration assisted oblique turning, part III: Experimental investigation, International J. of Mechanical Sciences, 63 (2012) 26–36.

M. J. Nategh, S. Amini and H. Soleimanimehr, Modeling the force, surface roughness and cutting temperature in ultrasonic vibrations-assisted turning of Al 7075, Advanced Materials Research, 83 (2010) 315–325.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Jihong Hwang

Hamed Razavi received his B.Sc. and M.Sc. in Mechanical Engineering from IAUN and Amirkabir University of Technology, Iran, in 2002 and 2005, respectively. He then received his Ph.D. from Tarbiat Modares University in 2012. Dr. Razavi is currently an Assistant Professor at the Department of Mechanical Engineering at Golpayegan University of Technology, in Golpayegan, Iran. His research interests include ultrasonic engineering, mechanical vibration and waves, metal forming and metal cutting, metrology, test and control of machine tools, automation, non-traditional manufacturing processes.

Rights and permissions

About this article

Cite this article

Razavi, H., Mirbagheri, M. Design and fabrication of a novel vibrational system for ultrasonic assisted oblique turning process. J Mech Sci Technol 30, 827–835 (2016). https://doi.org/10.1007/s12206-016-0137-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-016-0137-2