Abstract

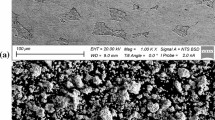

In this study, wear behavior of nanostructured Al and Al/2O3 nanocomposite samples prepared by an advanced technique called microwave- assisted hot press sintering process was investigated. The specimens were characterized by XRD analysis, pin-on-disk wear test and scanning electron microscopy observations. Compared to nanostructured Al, nanocomposite containing 4 wt-%Al2O3 showed a higher hardness of 175 HV and a lower wear rate of 7 × 10-3 mg m-1. Also, wear properties of hot-pressed samples were compared with those of nanocomposite conventionally prepared by Tavoosi et al. method. The results showed that contribution of ceramic particles in enhancing the wear resistance of nanocomposite can be eliminated by increased porosity content. Higher sintering temperature due to rapid heating rate of microwave-assisted hot press sintering method led to more densification and improvement in wear resistance in comparison with conventional method.

Similar content being viewed by others

References

G. Hirt, R. Cremer, T. Witulski, I. Kormendy, L. Kormendy and H. Tinius, Light weight near net shape components produced by thixoforming, Mater. Design, 18 (1997) 315–321.

O. Yilmaz and S. Buytoz, Abrasive wear of Al2O3-reinforced aluminium-based MMCs, Compos. Sci. Technol., 61 (2001) 2381–2392.

M. K ok and K. Özdin, Wear resistance of aluminium alloy and its composites reinforced by Al2O3 particles, J. Mater. Process. Technol., 183 (2007) 301–309.

M. Dao, L. Lu, R. J. Asaro, J. T. M. De Hosson and E. Ma, Toward a quantitative understanding of mechanical behavior of nanocrystalline metals, Acta Mater., 55 (2007) 4041–4065.

M. Tavoosi, F. Karimzadeh and M. H. Enayati, Wear behaviour of Al-Al2O3 nanocomposites prepared by mechanical alloying and hot pressing, Mater. Sci. Technol., 26 (2010) 1114–1119.

M. Oghbaei and O. Mirzaee, Microwave versus conventional sintering: A review of fundamentals, advantages and applications, J. Alloy. Compd., 494 (2010) 175–189.

A. Barba, C. Clausell, C. Feliu and M. Monzo, Sintering of (Cu0.25Ni0.25Zn0.50) Fe2O4 ferrite, J. Am. Ceram. Soc., 87 (2004) 571–577.

N. Saheb, Spark plasma and microwave sintering of Al6061 and Al2124 alloys, Int. J. Min. Metall. Mater., 20 (2013) 152–159.

A. H. Abdulhaqq, P. K. Ghosh, S. C. Jain and R. Subrata, The in?uence of porosity and particles content on dry sliding wear of cast insitu Al(Ti)-Al2O3(TiO2) composite, Wear, 265 (2008) 14–26.

N. Veil, Effect of variable parameters on mechanical properties of ceramic materials, High-temperature research, Moscow, Nauka (1967).

J. F. Archard, Contact and rubbing of flat surface, Appl. Phys., 24 (1953) 1–8.

N. P. Suh, Tribophysics, Prentice-Hall (1986).

M. Jafari, M. H. Enayati, M. H. Abbasi and F. Karimzadeh, Compressive and wear behaviors of bulk nanostructured Al2024 alloy, Mater. Design., 31 (2010) 663–669.

R. Chen, A. lwabuchi, T. Shimizu, H. S. Shin and H. Mifune, The sliding wear resistance behavior of NiAI and SiC particles reinforced aluminum alloy matrix composites, Wear, 213 (1997) 175–184.

A. M. Al-Qutub, I. M. Allam and M. A. A. Samad, Wear and friction of Al-Al2O3 composites at various sliding speeds, J. Mater. Sci., 43 (2008) 797–803.

E. Rabinowicz, Friction and wear of materials, New York, John Wiley and Sons (1995).

G. Kugler and M. Tercelj, Laboratory simulation of wear during hot extrusion of aluminium, Light Met. (2013) 515–520.

M. A. Herbert, R. Maiti, R. Mitra and M. Chakraborty, Wear behaviour of cast and mushy state rolled Al-4.5Cu alloy and in-situ Al4.5Cu-5TiB2 composite, Wear, 265 (2008) 1606.

B. Yalcin, Effect of porosity on the mechanical properties and wear performance of 2% copper reinforced sintered steel used in shock absorber piston production, J. Mater. Sci. Technol., 25 (2009) 577–582.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Jun-Sik Kim

Reza Abedinzadeh received his B.S. and M.S. degrees in Mechanics from Isfahan University of Technology, Iran in 2005 and 2007, respectively. He is a Ph.D. student of mechanical engineering at Isfahan University of Technology. His research activities include automation, modern machining, microwave processing, nanomaterials.

Rights and permissions

About this article

Cite this article

Abedinzadeh, R., Safavi, S.M. & Karimzadeh, F. A comparative study on wear properties of nanostructured Al and Al/Al2O3 nanocomposite prepared by microwave-assisted hot press sintering and conventional hot pressing. J Mech Sci Technol 29, 3685–3690 (2015). https://doi.org/10.1007/s12206-015-0813-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-015-0813-7