Abstract

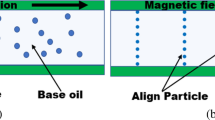

The magnetorheological (MR) damper is one of the utmost progressive applications of asemi-active damper. Uninterrupted controllability in both on and off state is an important factor of its plenitude application. Current research is attempting to make the damper more effective and efficient by minimizing the existing limitations such as MR fluid’s sedimentation, power consumption and temperature rising, and design optimization. We have broadly analyzed the optimization of MR dampers design with finite element simulation where various parameters of the MR damper have been considered for more accurate results. A prototype MR fluid has been prepared by coating the carbonyl iron particles with xanthan gum to reduce sedimentation. The SEM and Turbiscan results noticeably verify the improved sedimentation stability. In addition, a power-saving MR damper model has been developed by finite element analysis using ANSYS software. Prolonged operation raises the damper’s body temperature and degrades the performance. However, in this energy-saving MR damper model the temperature is not rising to a higher value compared to the conventional dampers, and consequently promotes damper efficiency.

Similar content being viewed by others

References

N. Mohammadi, M. J. Mahjoob, B. Kaffashi and S. Malakooti, An experimental evaluation of pre-yield and postyield rheological models of magnetic field dependent smart materials, JMST, 24 (9) (2010) 1829–1837.

S. W. Ko, J. Y. Lim, B. J. Park, M. S. Yang and H. J. Choi, Magnetorheological carbonyl iron particles doubly wrapped with polymer and carbon nanotube, J. of Applied Physics, 105 (7) (2009) 07E703.

J. Wanquan, Y. Zhang, S. Xuan, C. Guo and X. Gong, Dimorphic magnetorheological fluid with improved rheological properties, J. of Magnetism and Magnetic Materials, 323 (24) (2011) 3246–3250.

M. M. Ferdaus, M. M. Rashid and M. M. I. Bhuiyan, Development of an advanced semi-active damper using smart fluid, Advanced Materials Research, 939 (2014) 615–622.

Q. H. Nguyen, S.-B. Choi and J. K. Woo, Optimal design of magnetorheological fluid-based dampers for frontloaded washing machines, Proceedings of the Institution of Mechanical Engineers, Part C: J. of Mechanical Engineering Science, 228 (2) (2014) 294–306.

E.-K. Omar and H. Adeli, Recent advances on vibration control of structures under dynamic loading, Archives of Computational Methods in Engineering, 20 (4) (2013) 353–60.

B. Maryam, S. Hurlebaus and L. R. Barroso, Active and semi-active adaptive control for undamaged and damaged building structures under seismic load, Computer-Aided Civil and Infrastructure Engineering, 27 (1) (2012) 48–64.

Y.-J. Cha, J. Zhang, A. K. Agrawal, B. Dong, A. Friedman, S. J. Dyke and J. Ricles, Comparative studies of semiactive control strategies for MR dampers: Pure simulation and real-time hybrid tests, J. of Structural Engineering, 139 (7) (2013) 1237–1248.

M. M. Ferdaus, M. M. Rashid, M. H. Hasan and M. A. Rahman, Optimal design of Magneto-Rheological damper comparing different configurations by finite element analysis, JMST, 28 (9) (2014) 3667–3677.

J. H. Crews, M. G. Mattson and G. D. Buckner, Multiobjective control optimization for semi-active vehicle suspensions, J. of sound and Vibration, 330 (23) (2011) 5502–5516.

K. Ahn, D. Truong and M. Islam, Modeling of a magneto-rheological (MR) fluid damper using a self-tuning fuzzy mechanism, JMST, 23 (5) (2009) 1485–1499.

M. M. Ferdaus, M. M. Rashid, M. M. I. Bhuiyan, A. G. B. A. Muthalif and M. R. Hasan, Novel design of a self powered and self sensing magneto-rheological damper, IOP Conference Series: Materials Science and Engineering, IOP Publishing, 53 (1) (2013) 012048.

Y.-W. Yun, S.-M. Lee and M.-K. Park, A study on the efficiency improvement of a passive oil damper using an MR accumulator, JMST, 24 (11) (2010) 2297–2305.

Q.-H. Nguyen and S.-B. Choi, Optimal design of a vehicle magnetorheological damper considering the damping force and dynamic range, Smart materials and Structures, 18 (1) (2009) 015013.

Z. Parlak, T. Engin and I. Çalli, Optimal design of MR damper via finite element analyses of fluid dynamic and magnetic field, Mechatronics, 22 (6) (2012) 890–903.

Q. H. Nguyen, N. D. Nguyen and S. B. Choi, Optimal design and performance evaluation of a flow-mode MR damper for front-loaded washing machines, Asia Pacific Journal on Computational Engineering (2014).

J. Fan and Q. Wang, Optimal design and simulation of MR damper based on MATLAB, IEEE 3rd International Conference on Communication Software and Networks (ICCSN), China (2011) 661–663.

W. Jiang, H. Zhu, C. Guo, J. Li, Q. Xue, J. Feng and X. Gong, Poly (Methyl methacrylate)-coated carbonyl iron particles and their magnetorheological characteristics, Polymer International, 59 (7) (2010) 879–883.

H. B. Cheng, J. M. Wang, Q. J. Zhang and N. M. Wereley, Preparation and characterization of composite magnetic particles and aqueous magnetorheological fluids, J. of Physics: Conference Series, IOP Publishing, Germany (2009) 149 (1) 012044.

M. T. López-López, A. Zugaldía, F. González-Caballero and J. D. G. Durán, Sedimentation and redispersion phenomena in iron-based magnetorheological fluids, J. of Rheology, 50 (4) (2006) 543–560.

S. T. Lim, H. J. Choi and M. S. Jhon, Magnetorheological characterization of carbonyl iron-organoclay suspensions, IEEE Transactions on Magnetics, 41 (10) (2005) 3745–3747.

X. Zhang, W. Li and X. L. Gong, Study on magnetorheological shear thickening fluid, Smart Materials and Structures, 17 (1) (2008) 015051.

M. T. López-López, P. Kuzhir and G. Bossis, Magnetorheology of fiber suspensions, I. Experimental, J. of Rheology, 53 (1) (2009) 115–126.

G. T. Ngatu, N. M. Wereley, J. O. Karli and R. C. Bell, Dimorphic magnetorheological fluids: exploiting partial substitution of microspheres by nanowires, Smart Materials and Structures, 17 (4) (2008) 045022.

W. Jiang, Y. Zhang, S. Xuan, C. Guo and X. Gong, Dimorphic magnetorheological fluid with improved rheological properties, J. of Magnetism and Magnetic Materials, 323 (24) (2011) 3246–3250.

H. Böse and J. Ehrlich, Magnetorheological dampers with various designs of hybrid magnetic circuits, J. of Intelligent Material Systems and Structures, 23 (9) (2012) 979–987.

M. M. Ferdaus, M. M. Rashid, M. H. Hasan, H. B. M. Yosuf, M. M. I. Bhuiyan and A. Alraddadi, Temperature Effect Analysis on Magneto-Rheological Damper’s Performance, J. of Automation and Control Engineering, 2 (4) (2014) 392–396.

W. H. El-Aouar, Finite element analysis based modeling of magneto rheological dampers, M.S. Thesis, Virginia Polytechnic Institute and State University (2002).

S. M. H. B. Kasemi, Experimental investigation of magnetorheological fluid damper for semi-active vibration control, M.S. Thesis, International Islamic University Malaysia (2012).

K. W. Song, Y. S. Kim and G. S. Chang, Rheology of concentrated xanthan gum solutions: Steady shear flow behavior, Fibers and Polymers, 7 (2) (2006) 129–138.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Eung-Soo Shin

Muhammad Mahbubur Rashid (M’07) received the B.S. (Eng.) in Electrical and Electronic Engineering from Bangladesh University of Engineering and Technology, Dhaka, Bangladesh, in 1992, and the M.S. and Ph.D. in Electrical Engineering from the University of Malaya, Kuala Lumpur, Malaysia, in 2003 and 2007, respectively. Since 2007, he has been an Assistant Professor and Associate Professor in the Department of Mechatronics Engineering, International Islamic University Malaysia, Kuala Lumpur. His research interests include advanced control system and simulation and nonlinear modeling, industrial automation, instrumentation, neural networks, artificial intelligence, power electronics, and renewable energy.

Mohammad Meftahul Ferdaus received the B.S. (Eng.) dgree in Electrical and Electronic engineering from Rajshahi University of Engineering and Technology, Rajshahi, Bangladesh in 2011. His M.S. in Mechatronics Engineering is from International Islamic University Malaysia (2015). He is working as a research assistant in Mechatronics Engineering Department, International Islamic University Malaysia. His research interests are in vibration control, active and semi-active vehicle suspension system, smart materials and structure.

Muhammad Hasibul Hasan received his B.E. (Hons) in Mechanical Engineering, BUET, Bangladesh, M.S. (Eng) in Mechanical Engineering, Wayne State University, USA, Ph.D. in Mechanical Engineering, University of Nevada Las Vegas, USA. His current research interests are high temperature application of super alloys, ANN, creep-fatigue, fracture mechanics, reactive scheduling, value engineering and manufacturing engineering.

Ataur Rahman, Ph.D., is a Professor in the Department of Mechanical Engineering, Faculty of Engineering, International Islamic University Malaysia since 1996. His research interests are green transportation system: EV/HEV, hybrid engine, intelligent power train for hybrid and electrical vehicle, intelligent steering system and traction control system, electromagnetic actuated CVT and intelligent air-cushion vehicle for swamp and peat terrain.

Rights and permissions

About this article

Cite this article

Rashid, M.M., Ferdaus, M.M., Hasan, M.H. et al. ANSYS finite element design of an energy saving magneto-rheological damper with improved dispersion stability. J Mech Sci Technol 29, 2793–2802 (2015). https://doi.org/10.1007/s12206-015-0608-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-015-0608-x